Bioremediation of Liquid Waste Oil Through Bioreactor: A Case Study

Hasmawaty 1 *

Corresponding author Email: hasmawaty@binadarma.ac.id

DOI: http://dx.doi.org/10.12944/CWE.11.3.04

This article aims to explain the process of bioremediation of waste oils and found the rate of reaction kinetics model microbes. Samples were taken from liquid waste petroleum oil and gas companies Prabumulih South Sumatra, Indonesia. The isolation process using a medium Zobell’s and produces ten types of bacteria from the group Citrobacter sp, Micrococcaceaekarbon, and Flavobacterium sp. These bacteria’s is used in wastewater treatment bioreactor which have characteristic as follow: operate semi-continuously, using aeration column that contain polyurethane foam, variation of air discharge is 2 and 6 ml/sec, volume waste variation is 5 and 10 liters, 10 liters’ isolate, KNO3 (640 gram) and K2HPO4 (10 gram) as nutrition. The results showed that when bioremediation process contains 10 liters’ liquid waste, 10 liters’ isolate, and 6 ml/sec air discharge, it can reduce pH, specific gravity, BOD level, and the final weight of waste. Remediation process also increases the number of microbes, fatty oils and DO. Microbial maximum productivity is 59.50 with saturated concentration (Ks) at 3.25, and its slope is 0.43. Kinetics equation model following could be formulated as μ = 0.43/s/3.25+s.

Copy the following to cite this article:

Hasmawaty. Bioremediation of Liquid Waste Oil Through Bioreactor: A Case Study. Curr World Environ 2016;11(3). DOI:http://dx.doi.org/10.12944/CWE.11.3.04

Copy the following to cite this URL:

Hasmawaty. Bioremediation of Liquid Waste Oil Through Bioreactor: A Case Study. Curr World Environ 2016;11(3). Available from: http://www.cwejournal.org/?p=16531

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2016-11-03 |

|---|---|

| Accepted: | 2016-12-07 |

Introduction

Indonesia is one of the oil producers and consumer’s country. In 2014, Indonesia's oil production reached 289.878 million barrels.1 Indonesia's oil wells spread in several areas, both on land and sea. In the Province of South Sumatra, one of the regions that have oil wells is Prabumulih Municipality. In this city, oil drilling activity has begun in the 1950s by Pertamina, a state-owned Indonesian government, until today. In 2016, crude oil production in Prabumulih reaches 897.350 barrels per year.2 The existence of drilling activity and processing of crude oil have led to Prabumulih as a region which highly vulnerable to environmental pollution caused by wastewater. The liquid waste can be derived from the residual drilling mud, oil droplets, and formation water. This incident not only disrupts the activities of residents who mostly work as farmer’s rubber, but has the potential to worsen the quality of the environment.

Petroleum liquid waste containing aliphatic and aromatic hydrocarbon compounds that have a high molecular weight. In the aquatic environment, liquid waste petroleum can cause the diffusion of oxygen into the water. In the terrestrial environment, liquid waste petroleum can cause delays in the process of absorption of nutrients plant roots. Therefore, the liquid waste petroleum can cover the surface of roots under the soil surface. However, liquid waste oil can produce contamination of microorganisms in a location that makes petroleum hydrocarbons as a source of food and energy. In other words, the polluted environment of waste oils provides natural remedies to overcome environmental pollution caused by petroleum wastewater. This process is popularly known as bioremediation.

Bioremediation can be defined as a strategy, technique, methods, and approach to degrade pollutants and restore environmental quality using living organism, especially microorganism.3–5 It is part of biotechnology which represents the convergence of biology, computer science, chemistry, physics, and engineering. These component technologies work in synergy, and they are each advancing rapidly. Biotechnology is an important component needed to successfully achieve the goal of sustainability. “Value-added” products from by-products/waste and novel technologies employing biotechnical principles represent areas where significant opportunities exist.6 Bioremediation can clean unwanted substances from soil, water, air, and materials from industrial processing.7

To create genetically manipulated microorganisms, the metabolic pathways responsible for biodegradation of toxic compounds need to be understood, and the genes encoding the appropriate enzymes must be cloned and analyzed in detail8.Optimization of bioremediation processes generally requires the addition of inorganic materials (bio stimulation), such as utilizable sources of nitrogen, phosphorus, and oxygen.9 In bio stimulation, nutrients are injected into the subsurface to stimulate and enhance the growth of microorganisms. The injected nutrients, like nitrogen and phosphorus, are essential to the growth and activity of microorganisms.10

There are several technologies in common use, divided broadly between ex situ and in situ methods. Ex situ technologies usually involve the construction of windrows or bio piles, either on site or at a remote location. In situ technologies are much less obtrusive, involve significantly fewer earthworks, but also require longer treatment times and suffer from a lack of control compared to ex situ technologies.11 New bioremediation approaches are emerging based on advances in molecular biology and process engineering. Bioremediation continues to be the favored approach for processing biological wastes and avoiding microbial pathogenesis. Bioremediation may also play an increasing role in concentrating metals and radioactive materials to avoid toxicity or to recover metals for reuse.12

Bioremediation is still a popular and relevant topic, stimulating a vast number of important research.13 It can clean unwanted substances from soil14–17 and water.18–21 This research is designed to contribute to the scientific discussion about bioremediation, especially in the sectors of petroleum wastewater treatment.

Methods

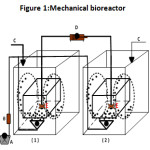

The study is conducting in two stages: isolation of samples (isolation, purification, selection, rejuvenation of isolates culture, and producing mix-culture) and bioremediation with continuous semi-batch process. We use completely randomized design as research design. It is consisting two factorial treatments: the volume of petroleum liquid waste (R1 = adding 5 liters’ liquid waste for 100 liters at medium; R2 = adding 10 liter’s liquid waste for 100 liter’s at medium) and air discharge as aeration (Q1 = 2 liter’s/second; Q2 = 6 liter’s/second). The total number of treatment combination is four unit, and each unit will be repeated twice so that it will produce eight experiments. We make bioreactor from the glass and consist two boxes. The first box has size 40 x 40 x 80 cm.3 In the first box, we put the second box which size 28 x 28 x 40 cm3 (see, Figure 1). We treat this bioreactor with the continues semi-batch process with agitation speed reaches 120 rpm.

|

|

Note: A (air pump), B (flow meter), C (waste, nutrition, and isolate aquades), D (motor), and E (agitator)

We measure several variables such as decreasing pH medium, specific gravity, BOD, the final weight of waste, increasing the waste solubility, and DO. We collected liquid waste sample from the waste container vessel owned by Pertamina located in Prabumulih Municipality. For isolation samples, we borrow laboratories facility at Laboratory of Microbiology, Faculty of Mathematics and Natural Sciences, Sriwijaya University. While bioremediation process carried out at the Laboratory of Chemistry, Chemical Engineering, Sriwijaya Polytechnic, Palembang. The final results of the analysis will be compared to the environmental quality standards (BML) is arranged in South Sumatra Governor Regulation Number 18/2005 on Standard Quality for Liquid Waste (see Table 1).

Table 1: Standard quality for oil liquid waste

|

No |

Parameter |

Unit |

Type of standards quality |

|

|

I |

II |

|||

|

1 |

pH |

unit |

6-9 |

6-9 |

|

2 |

BOD5 |

mg/l |

50 |

150 |

|

3 |

COD |

mg/l |

100 |

300 |

Result

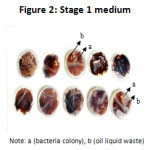

In the first step (isolation process), we get ten bacteria and labelling them as A, B, C, D, E, F, G, H, I, and J. All of them are bacillus, gram-negative, do not spore, and able to grow at medium containing petroleum waste (see Figure 2). They are a part of Citrobacter sp, Micrococcaceaekarbon, and Flavobacterium. The addition of KNO3 and K2HPO4 simultaneously will decreasing the value of the specific gravity and the final weight of waste. The use of aeration in bioremediation processes greatly affect the effectiveness of mixed cultures of bacterial metabolism to degrade hydrocarbons. It is indicated by decreasing value of pH medium, specific gravity, the final weight of the waste, and BOD. For pH and BOD value, our data show that they are lower than threshold value as regulated by South Sumatra Governor Regulation Number 18/2005 on Standard Quality for Liquid Waste. At the same time, it increases the solubility waste, the number of microbes and fatty oils.

|

|

As shown in Table 2, the second treatment (R2 and Q2) give better effect against microbes growth (Pm = xm/tm) when compared to the first treatment (R1 and Q1). For example, when we give substrate from five liter to ten liter, microbe productivity increased from 57.5 to 59.5. In other word, the speed and acceleration of microbes growth rate are better when the provision of oxygen is proper. Based on saturated coefficient (Ks) at 3.25, and its slope is 0.43, kinetics equation model for bioremediation process could be formulated as μ = 0.43 s/3.25+s.

Table 2: Microbes productivity

|

Q, 2 ml/sec |

|||||

|

5 (liter) |

10 (liter) |

||||

|

Xm |

Tm |

Pm |

Xm |

Tm |

Pm |

|

1.87 |

10 |

18.7 |

3.50 |

10 |

35.0 |

|

Q, 6 ml/sec |

|||||

|

5 (liter) |

10 (liter) |

||||

|

Xm |

Tm |

Pm |

Xm |

Tm |

Pm |

|

5.75 |

10 |

57.5 |

5.95 |

10 |

59.5 |

Discussion

The results of this study reinforce previous few prepositions in research on bioremediation, namely: first, environmental pollution, especially those derived from petroleum processing, can be solved by identifying and maximizing indigenous bacteria. Second, the use of nutrients in the right proportions can optimize bioremediation process. In the future, research on bioremediation should not only focus on to identify the type of bacteria that have the best ability to degrade petroleum waste. However, it needs to be directed to determine the types of compounds that occur after bioremediation, analyze microbes that prefer to use straight-chain hydrocarbon or a ring shape, and validated with toxicity tests.

Acknowledgement

The research was funded by Center for Research, Development, and Regional Innovation South Sumatra Province (BALITBANGNOVDA) through contract number: 500.a/kptsbalitbangda/2013, 07 July 2013. Part of this paper has been presented at the seminar on “Assessment of Potential Industrial Development Zone in South Sumatra”, organized by BALITBANGNOVDA in the Palembang City, 18 December 2013. Researchers would like to thanks to all the people who have helped this study.

Reference

- Badan Pusat Statistik. Environment Statistics of Indonesia 2015. (Badan Pusat Statistik, 2015). doi:10.1017/CBO9781107415324.004

CrossRef - BPS Kota Prabumulih. Prabumulih Municipality in Figures 2016. (BPS Kota Prabumulih, 2016).

- Naseri, M., Barabadi, A. & Barabady, J. Bioremediation treatment of hydrocarbon-contaminated Arctic soils: influencing parameters. Environmental Science and Pollution Research 21, 11250–11265 (2014).

CrossRef - Atlas, R. M. & Cerniglia, C. E. Bioremediation of petroleum pollutants. International Biodeterioration and Biodegradation 45, 332–338 (1995).

- Crawford, R. L. in Bioremediation: principle and application (eds. Crawford, R. L. & Crawford, D. L.) 1–2 (Cambridge University Press, 1996).

CrossRef - Englande, A. J. & Jin, G. Application of biotechnology in waste management for sustainable development. Management of Environmental Quality: An International Journal17, 467–477 (2006).

CrossRef - Rowley, W. R. Biotechnology overview. Foresight 4, 4–13 (2002).

CrossRef - Pohland, F. G. & Tedder, D. W. Emerging Technologies in Hazardous Waste Management V An Overview. 1–8 (1995).

- Crawford, R. L. & Rosenberg, E. Bioremediation. The Prokaryotes: Applied Bacteriology and Biotechnology (Springer Berlin Heidelberg, 2013). doi:10.1007/978-3-642-31331-8

CrossRef - Drell, D., Palmisano, A. & Broido, M. Ethical, Legal, and Societal Implications of Bioremediation. Natural Resources & Environment 13, 533–536 (1999).

- Gillespie, I. M. M. & Philp, J. C. Bioremediation, an environmental remediation technology for the bioeconomy. Trends in Biotechnology 31, 329–332 (2013).

CrossRef - Bonaventura, C. & Johnson, F. M. Healthy environments for healthy people: bioremediation today and tomorrow. Environmental Health Perspectives 105, 5–20 (1997).

CrossRef - Puglisi, E., Trevisan, M., Grotenhuis, T. & Adrian, L. EUROSOIL 2012 bioremediation session: preface to special issue. Biodegradation 24, 451–453 (2013).

CrossRef - Hanson, K. G., Nigam, A., Kapadia, M. & Desai, A. J. Bioremediation of crude oil contamination with Acinetobacter sp. A3. Current Microbiology 35, 191–193 (1997).

CrossRef - Tissot, P. Calorimetric study of the bioremediation of a polluted soil. Journal of Thermal Analysis and Calorimetry 57, 303–312 (1999).

CrossRef - Margesin, R., Hämmerle, M. & Tscherko, D. Microbial activity and community composition during bioremediation of diesel-oil-contaminated soil: Effects of hydrocarbon concentration, fertilizers, and incubation time. Microbial Ecology 53, 259–269 (2007).

CrossRef - Lin, X. et al. Changes in microbial populations and enzyme activities during the bioremediation of oil-contaminated soil. Bulletin of Environmental Contamination and Toxicology 83, 542–547 (2009).

CrossRef - Bhadbhade, B. J., Sarnaik, S. S. & Kanekar, P. P. Bioremediation of an Industrial Effluent Containing Monocrotophos. Current Microbiology 45, 346–349 (2002).

CrossRef - Dash, H. R., Mangwani, N., Chakraborty, J., Kumari, S. & Das, S. Marine bacteria: potential candidates for enhanced bioremediation. Applied Microbiology and Biotechnology 97, 561–571 (2013).

CrossRef - Ojumu, T. V, Bello, O. O., Sonibare, J. A. & Solomon, B. O. Evaluation of microbial systems for bioremediation of petroleum refinery effluents in Nigeria. African Journal of Biotechnology 4, 31–35 (2005).

- Kumar, R., Singh, P., Dhir, B., Sharma, A. K. & Mehta, D. Potential of Some Fungal and Bacterial Species in Bioremediation of Heavy Metals. Journal of Nuclear Physics, Material Sciences, Radiation and Applications 1, 213–223 (2014).

CrossRef