An Experimental Investigation of the Efficiency of A Stationary Helical Solar Water Heater

Mojtaba Moravej1,2 * and Abdolkarim Soozanyar2

DOI: http://dx.doi.org/10.12944/CWE.12.2.08

The shape and geometry of a solar collector is an important factor in solar-to-thermal energy conversion. In this paper, a new stationary solar collector called helical solar collector was designed and investigated. The performance of this collector was experimentally studied using ASHRAE standard. Experiments were performed with water as a working fluid in the outdoor condition of Ahwaz, a city in the south of Iran. The findings indicate that the average of its thermal efficiency is about 53%, and that it can be used as an efficient new water heater. The experiments show that the efficiency of the helical solar water heater increases through adding the mass flow rate.

Copy the following to cite this article:

Moravej M, Soozanyar A. An Experimental Investigation of the Efficiency of A Stationary Helical Solar Water Heater. Curr World Environ 2017;12(2). DOI:http://dx.doi.org/10.12944/CWE.12.2.08

Copy the following to cite this URL:

Moravej M, Soozanyar A. An Experimental Investigation of the Efficiency of A Stationary Helical Solar Water Heater. Curr World Environ 2017;12(2). Available from: http://www.cwejournal.org/?p=17292

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2016-03-12 |

|---|---|

| Accepted: | 2017-07-10 |

Introduction

Due to increasing demand for energy and rising cost of fossil fuels, solar energy is considered an attractive source of green energy that can be used to heat water in domestic and industrial sectors. Solar water heating systems generally consist of a solar radiation collector, working fluid, a storage tank, a pump, a piping unit and an auxiliary heating unit.1, 2 The most important factor in solar water heating is its efficiency. The efficiency of a solar water heating system is based on the proportion of useful energy that is received from the heated water to solar irradiance.5,6 Solar collectors' properties play the main role in the efficiency of solar water heating systems [7]. Scientists and engineers have been seeking new ways to increase the performance of solar water heating systems in order to increase their performance and utility and to lower their costs. Numerous studies have investigated ways to increase the efficiency of solar collectors worldwide. Kalogirou reviewed several different types of solar thermal collectors and provided the relative thermal analysis and applications of each type.8-12

|

Table 1 Click here to View figure |

The efficiency value of a solar collector is largely affected by its absorbent surface.13 The color, configuration factors and the heat transfer between the absorbent and working fluid are also important.14,15 The amount of heat transfer is a function of the employed working fluid, the type of contact between the absorbent and working fluid, area and the geometry of the absorbent and the collector.16,17 Many studies are carried out on heat transfer between the absorbent and working fluid and some focus on the geometry of the absorbent and the collector. These studies recommend gas-particle suspension,18 fluid-film19 and metal-foam20 to increase heat transfer. To maximize the overall incident radiation for a surface, solar tracking mechanisms are used, which can lead to an increase in the yearly solar radiation gain up to 1.45 times compared with optimal tilted solar collectors.21 Since the operation of such tracking mechanisms is complicated, they are not cost-effective to be used in solar heating systems. Employing an appropriate and symmetric surface as in spherical or helical collectors makes it possible to eliminate the tracking mechanism with no obvious loss in their efficiency. The spherical solar collector has already been investigated by some researchers.22,23

In this study, the efficiency of a helical solar collector with new geometry is experimentally investigated. To obtain the efficiency of this collector, mass flow rate of the water as a working fluid, the heat transfer from the collector to the water and the solar energy received by the collector were measured.

Materials and Methods

In the present work, a novel type of stationary collector, namely, helical solar collector is proposed. It consists of a conical body, a glass cover, piping around the absorbing plate, isolated surface and working fluid that are shown in the Fig. 1.

The main benefit of the helical collector is that it has symmetric sections in every side and has circular section when the incident beam radiation is normal to it at the top of collector shown in Fig. 2.

This configuration enables this collector to collect incident beam radiation during the day. Other profits of this collector and the drawbacks of the existing collectors such as a flat plate solar water heater, as a common stationary solar collector, are shown in Table1

|

|

|

|

Table 1: Comparison between flat plate and conical solar collectors

| Conical solar collector | Flat plate solar collector | Specification |

| 1 m2 | 1 m2 | Absorber area |

| Copper with 6.2 mm | Copper with 6.2 mm | Piping |

| - | Metal fixture with 45 tilt angle | Fixture |

| Only bottom | Edge sides | Isolation |

| Bottom | ||

| Every sides | Only upper side | Absorption ability of sunshine |

| Has symmetric geometry and do not need any recommendation for install | According to location | Install recommendation |

| 7,500,000 | 8,030,000 | Total cost (Iran Rials) |

Experimental procedure

The schematic of the experimental is shown in Fig.4. This helical solar collector was experimentally investigated at the Shahid Chamran University of Ahvaz, Iran (latitude is 310 19' 16'' N and longitude is 480 40' 16'' E). The relative collector position is shown in Fig. 3.

|

|

The specifications of the helical solar collector used in this experimental test are presented in Table 2. The tilt angle of the collector is always 900, so it is normal to the earth in every location.

Table 2: Specifications of the helical solar collector

|

Specification |

Dimension |

Unit |

|

Diameter of absorber (conical body) |

0.6 |

m |

|

Absorber area |

1.0 |

m2 |

|

Absorber high (Con altitude) |

1.07 |

m |

|

Absorber thickness |

1.5 |

mm |

|

Thickness of Frame (totally glass) |

6 |

mm |

|

Thickness of pipe Diameter of pipe |

1.1 6.2 |

mm mm |

|

Weight |

34 |

Kg |

|

Thickness of Insulation (Polystyrene and wood) |

20 |

mm |

The solar system is a force convection system with an electrical pump (6 in Fig. 4). As shown in this figure, it does not have any cycles, so the system is open. Water was used as a working fluid in this collector. A flow meter (4 in Fig. 4) was connected to the water tube before the electrical pump. Three K thermocouples were used to gauge the air temperature (10 in Fig. 4) and the fluid temperature in the inlet (3 in Fig. 4) and outlet (2 in Fig. 4) of the helical collector. These thermocouples were connected to a channel data logger (TES data logger model). A TES solar meter was used to record the solar radiation. The calibration of the gauging instrument was undertaken before, during and after the experimental data gathering. An independently calibrated platinum resistance thermometer was employed to regulate the thermocouples; the flow meter was adjusted using a data logging sub-routine for water draw off from the collector into a container and measuring the mass with accuracy scales, and the solar meter using a calibrated reference solar meter with a valid calibration certificate.

|

|

Test method

ASHRAE Standard for testing the thermal efficiency of collectors is definitely the most widely used standard employed to test the performance of stationary solar water heater.24 The thermal performance of the solar collector is established by getting the values of instantaneous performance for different combinations of received radiation, ambient air and inlet fluid temperature.25 It necessitates experimental measurements to obtain the level of incident radiation and the amount of energy added to the working fluid circulating the collector at either steady state or quasi-steady-state conditions.

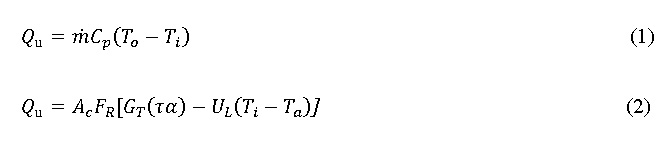

ASHRAE Standard recommends performing the experiments in various inlet fluid temperatures. After steady state conditions, the result for each test are averaged and used to derive a single point while other results are rejected. As the mass flow rate and input and output fluid temperatures of the fluid are measured, the useful energy can be obtained by means of equation (1). The useful energy can also be described on the basis of the energy taken in by the absorber and the energy lost from it as stated by equation (2).

Where, Cp is the heat capacity of the working fluid.

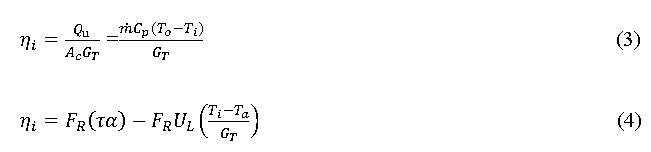

The instantaneous collector efficiency relates the useful energy to the total incident radiation on the collector surface by equation (3) or (4).

FR(ζα) and FR UL are absorbed energy and energy loss parameters respectively. After testing the thermal efficiency of the solar collector , FR(ζα) and FR UL can be calculated from the obtained data. Both FR(ζα) and FR UL remain unchanged when the efficiency tests are administered near the normal incidence conditions. Based on Eq. (4), if the data of efficiency tests are plotted, it will be a straight line with vertical axis as efficiency against (Ti-Ta/GT) as the horizontal axis. The intersection point of this line with the vertical axis shows the peak collector efficiency, when the inlet temperature of the collector is close to the ambient temperature. Also, at the intersection of this line with horizontal axis, stagnation point, the collector efficiency is zero and usually happens when the working fluid stops flowing through in the system.

Results and Discussions

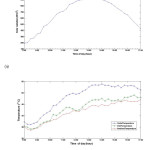

The experimental results consist of efficiency and changes in inlet-outlet temperatures in the helical solar collector. All the data were tested in a quasi-steady state condition. In each test, the highest differences in the inlet, outlet and ambient temperatures are 0.6, 0.6 and 0.5 0 C, respectively and 19W/m2 for solar radiation. The collector tilt angle is 90 0 and normal to the earth and use usual water as working fluid. The tests were performed for many days in the latter part of summer during the day time at 8.00 to 17.00. The data were logged every 15 minutes. The experimental findings are given in the form of equations and graphs expressing the collector's efficiency. Figure 5 illustrates typical data for working fluid at 1.1 Lit/min in one of the test days.

|

|

According to the experimental data and equation (3), the average efficiency of the helical solar collector in the outdoor condition of the test area was about 53%, which is suitable to use for a solar water heating system in houses. Figure 5 shows that the difference between the inlet and outlet temperatures is high enough to use it as an appropriate solar water heater.

|

|

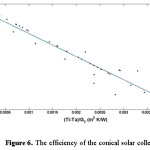

Figure 6 shows the variation of collector efficiency versus the reduced temperature parameters, (Ti–Ta)/GT during the tests. According to equation (4) the efficiency of the helical collector decreases with increasing this parameter. Experimental results are fitted with linear equations to calculate the characteristic parameters of this solar collector. The collector efficiency parameters, and , are 25.91 and 0.585 respectively and the goodness parameter of the fitness, R2, is 0.937 , which shows suitable fitting. These results are similar to previous works of Yousefi et al 2-4 and Goudarzi et al.9

|

|

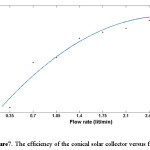

Figure 7 illustrates the impact of flow rate on thermal efficiency of the conical solar collector. Based on this figure, the efficiency of the collector increases by adding to the flow rate. This trend is in line with the experimental works of Minsta et al. 26 and Cristofari et al.27 in that they studied the effect of mass flow rate on a solar collector.

Conclusion

In this study, the efficiency and performance of a novel stationary solar collector with conical geometry was experimentally investigated. The temperature changes in the collector were experimented. The findings indicate that the average efficiency of a helical collector with 1 m2 of absorber plate and 0.6 m diameter is about 53%. As shown in the diagrams, the instantaneous efficiency of the helical solar collector decreases as the ratio of temperature to incident radiation increases. The experiments showed that the difference between the inlet and outlet temperatures and the efficiency of the conical solar collector is satisfactory both in the morning and in the afternoon due to its special geometry. In addition, the experiments showed that the efficiency of the conical solar collector increases by adding to the mass flow rate.

Acknowledgment

The authors would like to thank shahid Chamran University of Ahvaz for support.

References

- Esen, M.&Esen, H. Experimental investigation of a two-phase closed thermosyphon solar water heater. Solar Energy 79, 459-468, 2005.

CrossRef - Yousefi, T., Shojaeizadeh, E., Veysi, F. &Zinadini, S. An experimental investigation on the effect of pH variation of MWCNT-H2O nanofluid on the efficiency of flat plate solar collector. Solar Energy 86, 771-779, 2012.

CrossRef - Yousefi, T., Veysi, F., Shojaeizadeh, E. &Zinadini, S. An experimental investigation on the effect of MWCNT-H 2 O nanofluid on the efficiency of flat-plate solar collectors. Experimental Thermal and Fluid Science 39, 207-212, 2012.

CrossRef - Yousefi, T., Veysi, F., Shojaeizadeh, E. & Zinadini, S. An experimental investigation on the effect of Al 2 O 3–H 2 O nanofluid on the efficiency of flat-plate solar collectors.Renewable Energy 39.1, 293-298, 2012.

CrossRef - Chen, Z., Furbo, S., Perers, B., Fan, J.& Andersen, A. Efficiencies of flat plate solar collectors at different flow rates. Energy Procedia 30, 65-72, 2012.

CrossRef - Kalogirou, S. Prediction of flat plate collector performance parameters using artificial neural networks. Solar Energy 80, 248-259, 2006.

CrossRef - Kalogirou, S. Solar thermal collectors and applications. Progress in Energy and Combustion Science 30, 231-295, 2004.

CrossRef - Tian, Y.& Zhao, C. Y. A review of solar collectors and thermal energy storage in solar thermal applications.Applied Energy 104, 538-553, 2013.

CrossRef - Goudarzi, K., Shojaeizadeh, E. & Nejati, F. An experimental investigation on the simultaneous effect of CuO–H 2 O nanofluid and receiver helical pipe on the thermal efficiency of a cylindrical solar collector. Applied Thermal Engineering 73.1,1236-1243, 2014.

CrossRef - Moghadam, A.J., Farzane-Gord, M., Sajadi, M. & Hoseyn-Zadeh, M. Effects of CuO/water nanofluid on the efficiency of a flat-plate solar collector.Experimental Thermal and Fluid Science58, 9-14, 2014.

CrossRef - Esen, M.&Esen, H. Experimental investigation of a two-phase closed thermosyphon solar water heater. Solar Energy 76, 751-757, 2004.

CrossRef - Zambolina, E.& Del, D. Experimental analysis of thermal performance a flat plate and evacuated tube solar collectors in stationary standard and daily condition. Solar Energy 84, 1382-1396, 2010.

CrossRef - Bogaerts, W. F.& Lampert, C. M. Materials for photothermal solar-energy conversion. Journal of Materials Science 18, 2847-2875, 1983.

CrossRef - Tripanagnostopouios, Y., Souliotis,.M.&Nousia, TH.Solar collectors with colored.Solar Energy 68, 343-5, 2000.

CrossRef - Orel, Z., Gunde, M.&Hutchinc, M. Spectrally selective solar absorbers in different Non-black colours. Solar Energy Materials and Solar Cells 85, 41-50, 2005.

- Close, D. J. Solar air heaters for low and moderate temperature applications. Solar Energy 7, 117-24, 1963.

CrossRef - Kolb, A., Winter, E.&Viskanta, R. Experimental studies on a solar air collector with Metal matrix absorber. Solar Energy 65, 91-8, 1999.

CrossRef - Bertocchi, R., Karni, J. &Kribus, A. Experimental evaluation of a non-isothermal high temperature solar partier.Receiver Energy 29, 687-700, 2004.

CrossRef - Bohn, M. S. & Wang, K. Y. Experiments and analysis on the molten Salt direct absorption receiver concept.ASME Journal of Solar Energy Engineering 110, 45-51, 1988.

CrossRef - Fend, T., Pitz-paal, R., Reutter, O., Bauer, J.&Hoffschmid, B. Two novel high-porosity materials as volumetric receivers for concentrated solar radiation.Solar Energy Materials and Solar Cells 84, 291-304, 2004.

CrossRef - Mousazaeh, H. A review of principal and sun-tracking methods for maximizing solar systems output. Renewable and Sustainable Energy Reviews 13: 1800-1818, 2009.

CrossRef - Samanta, B.&Khamis Rajab AI Balushi.Estimation of incident radiation on a novel spherical solar collector.Renewable Energy 14, 241-247, 1998.|

CrossRef - Pelece, I., Iljins, U., Ziemelis, E.&Ziemelis, I. Theoretical calculation of energy received by semi-spherical solar collector. Proceeding of the International scientific Conference ‘’Engineering of Agricultural Technologies 2008’’, Latvia. P: 263-269, 2008.

- ASHRAE Standard 93-86. Methods of testing and determine the thermal performance of solar collectors. Atlanta, GA, USA, 1986.

- Duffie, J. A.& Beckman. W. A. Solar Engineering of Thermal Processes. fourth edition. Wiley, 2013.

CrossRef - Mintsa Do Ango, A. C., Medale, M.&Abid, C. Optimization of the design of a polymer flat plate solar collector.Solar Energy 87, 64-75, 2013.

CrossRef - Cristofari, C., Notton, G., Poggi, P. & Louche, A. Mmodeling and performance of a copolymer solar water heating collector,Solar Energy, vol.72, pp. 99-112, 2002.

CrossRef