The Effect of Utilizing Rice Husk Ash on Some Properties of Concrete - A Review

1

Department of Civil Engineering,

CGCTC,

Jhanjeri,

India

2

Department of Civil Engineering,

PAU Ludhiana,

India

Corresponding author Email: deepaulakh4@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.13.2.07

Copy the following to cite this article:

Aulakh D. S, Singh J, Kumar S. The Effect of Utilizing Rice Husk Ash on Some Properties of Concrete – A Review. Curr World Environ 2018;13(2). DOI:http://dx.doi.org/10.12944/CWE.13.2.07

Copy the following to cite this URL:

Aulakh D. S, Singh J, Kumar S. The Effect of Utilizing Rice Husk Ash on Some Properties of Concrete – A Review. Curr World Environ 2018;13(2). Available from: http://www.cwejournal.org?p=1079/

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2018-04-04 |

|---|---|

| Accepted: | 2018-06-26 |

| Reviewed by: |

Dr. Ozgur Ekincioglu (Turkey)

Dr. Ozgur Ekincioglu (Turkey)

|

| Second Review by: |

Dr. Payam Shafigh (Malaysia)

Dr. Payam Shafigh (Malaysia)

|

| Final Approval by: | Dr. Umesh Chandra Kulshrestha |

The major environmental issues emerge these days are change in the climate, drain of the resources and so on. The climatic changes are increasing air contamination such as smog, depletion of ozone layer, greenhouse effect etc., which is a fundamental concern for researchers nowadays. The utilization of cement for urbanization and industrialization is significant cause for the air contamination because 10 quintal of CO2 emitted from the manufacturing of 10 quintal of cement, which contributes to 5–7% of CO2 emissions in global warming.1-3 Several industrial and agricultural by-products such as blast furnace slag, rice husk ash (RHA), fly ash, condensed silica fume (SF), wood waste ash, coconut shell &fibers etc. might be adopted as an add-on cementitious substantial in order to reduce CO2 emissions.4-9

Size, fineness of the particle, surface area, silica crystallization phase, silica content, 24 It was found from the study that the mechanical strength of the mortar increases with 10% by weight RHA replacement with cement.25,26 From the previous study, it was concluded that fractional substitution of cement by RHA reduces the heat of hydration, improves the strength which is making concrete more economical and also environmental friendly.

In the present review paper, the results and discussion of some researchers on using rice husk ash (RHA) as additional cementitious material on the properties of concrete like compressive strength, workability, permeability and tensile strength are reviewed.

Properties of Rice Husk Ash

The color of rice husk ash depends upon the source of raw material, process, time, duration and temperature of burning and varies from whitish grey to black. According to the code IS 456, RHA is categorized as N type pozzolana.27 Table 1 enlists the chemical properties and table 2 depicts the physical properties of RHA respectively.

Table1 enlists the components of RHA and cement. It is well known fact that the main binding component of cement is CaO, which is also a constituent of RHA although lower in percentage that cement. It can be observed from the table that all other components are nearly similar in both RHA and cement. Therefore, RHA can also be used a fractional substution of cement in concrete.

Table 1: Chemical Properties of RHA by Weight %age19,28-33are:

|

Component |

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

SO3 |

Na2O |

K2O |

LOI* |

|

RHA |

86.8 -95.1 |

0.2 - 0.5 |

0.1 -0.9 |

0.5 -2.9 |

0.3 -0.9 |

0.0 -1.2 |

0.1 -1.0 |

0.5 -3.1 |

0.5 -8.5 |

|

Cement |

21.8-22.0 |

4.7-5.5 |

2.3-3.4 |

60.5 - 61.6 |

2.6 - 4.3 |

2.0 - 2.2 |

0.1 - 0.4 |

0.7 - 1.1 |

0.5 - 2.3 |

Table 2: Physical Properties of rice husk ash given by various authors33-40are:

|

Property |

Specific gravity |

Specific surface area (m2/kg) |

Pozzolanic activity Index (%) |

Bulk density (Kg/m3) |

Median particle size (μm) |

Nitrogen adsorption (m2/kg) |

Surface area, (cm2/g) |

|

RHA |

2.1 - 2.2 |

240.0 -376.8 |

81.3 - 88.9 |

420.0 - 429.1 |

5.0 - 7.4 |

24.3 - 28.8 |

4091 - 5685 |

|

Cement |

3.1 - 3.3 |

3310 |

- |

830 - 1650 |

4.6 – 10.5 |

- |

- |

Properties of Concrete Containing RHA

Workability

The effortlessness with which concrete can be mixed, transported and placed is known as workability. As a permeable material, fractional substitution of RHA in cement diminishes the workability of fresh concrete. Although, the workability can be improve by the use of high-quality superplasticizer. Salas et al., determined that with 15 or 20% RHA, the mix becomes stiffer therefore extra super plasticizer has been required to keep up the vital workability.41 Suaiam and Makul stated that by replacing RHA up to 25% gives the adequate results whereas if fine aggregates are partially replaced by the large quantity of RHA, workability is going to decrease.42 Le et al., find out the consequence of various percentage of RHA on high performance fine grained concrete and found that as the RHA content amplify workability decline because of huge specific surface area of RHA.43 Due to huge surface area and carbon content in RHA, a large quantity of water reducing admixture to be used for maintaining the constant workability than that of the controlled concrete.43 The workability of concrete containing two different RHAs, one controlled combustion rice husk ash from USA while the other uncontrolled combustion rice husk ash from Uruguay were explored and it was found that uncontrolled combustion rice husk ash concrete require less superplasticizer as compared controlled combustion rice husk ash concrete due to low unconsumed carbon content.44

Safiuddin et al., studied that the concrete made with super plasticizer (3.5 to 4.5%), RHA (5 to 30%) and water cement ratio (0.30 to 0.40) exhibited 265–280 mm slump which is same as of 0% RHA concrete, however the deformability of concrete enhanced significantly.17 Sensale performed slump test and found that normal concrete exhibit medium workability (52mm), whereas for RHA concrete possesses low workability (45-48mm). Nagrale et al., stated that with increase in RHA in concrete the water required for workable mix increases due to increase of the fineness material in the concrete.45 It was revealed from the literature that specific surface area, void size scattering, and water demand of RHA were the key factor controlling the flowability of mortar.46 Moulick stated the reason for the low slump that with the increase in the RHA quantity by weight increase the concrete volume, as density of cement higher that the RHA i.e. 3.11g/cm3 as compare to 2.1 g/cm3 in RHA.47

Compressive Strength

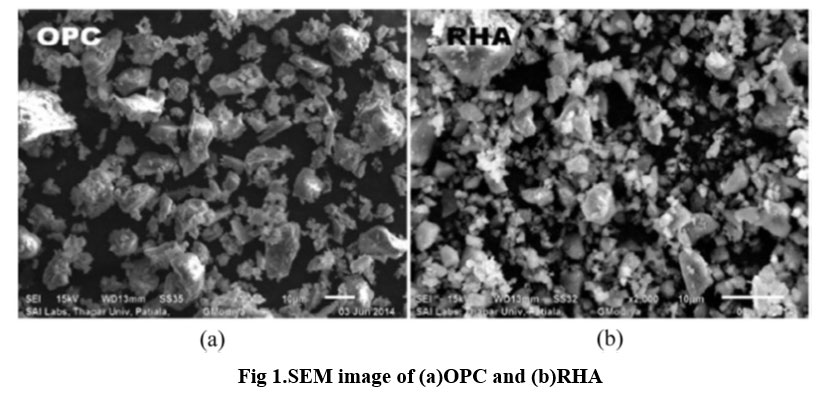

From the previous study it had been found that the strength increases with partial substitution RHA in concrete.29,48,49 Most suitable RHA replacement varies from 5% to 30% by weight of cement. Specific surface area and bulk density of RHA are the important parameters affecting cement properties. As the specific surface area increase, it displays a remarkable pozzolanicity by consuming calcium hydroxide present in concrete, whereas the bulk density escalates the mechanical strength due to less void fraction. Replacing cement with 10% RHA increase the compressive strength irrespectively to ages due to high pozzolanicity and silica content.23,30,50 Lung et al., examined RHA and normal concrete properties and concluded that at 7, 14 and 28 days strength are 47MPa,52 MPa, 61MPa and 50MPa, 54MPa, 56 MPa respectively.30 Muthadhi et al., and Ganesan et al., detected that the existence of amorphous silica and fine particle size of RHA, 20%RHA concrete exhibits the maximum compressive strength.48,49 Figure 1 depicts the SEM of ordinary Portland cement and rice husk ash.32

|

Figure 1: SEM image of (a)OPC and (b)RHA Click here to view figure |

(chemical activator) and 21,51 Salas et al., observed that compressive strength increase significantly by replacing 5–10% cement with RHA.41 Suaiam and Makul detected diminution in the compressive strength with each replacement of fine aggregates with 0–100% RHA.42 Siddique et al., found 10.2%, 11.8% and 14.7% upsurge in the strength of RHA and (Bacillus aerius strain) bacteria concrete than normal concrete at 7, 28 and 56 days respectively because of the calcite generation in the voids of cement sand.22 Kulkarni et al., found that by varying RHA percentage from 0 to 30 % there was slight increase in the strength (0.75%-4%) at 7th day, whereas there was significant increase in the strength (7.5%-15.5%) except 30% RHA replacement gave same result as normal concrete at 28th day.52

Tensile Strength

ratio of water to cement are 0.35, 0.50, 0.65 % respectively had exhibited 9%, 33% and 43% additional strength then conventional concrete after 91 days of curing.4SO2Gastaldini et al., and Chindaprasirt et al. revealed that concrete with 20% RHA, 1% K

Madandoust et al., observed that concrete with 20% RHA replacement had a splitting tensile 53 respectively which is much greater than the normal concrete, but suffered a great fall with 30% RHA substitution.2 Another study was conducted by Saraswathy and Song with 15%, 20%, 25% and 30% RHA replacement in concrete on cylindrical samples and observed that split tensile strength of various percentages RHA concrete were 4.92, 4.60, 4.58 and 3.67 N/mm.41 Salas and group observed that RHA concrete exhibit remarkable results of flexural tensile strength than conventional concrete.50 Tensile strength is the resistance of a material to fail under tension. As the compressive strength increase with curing period, so do tensile strength. Alex J et al., examined the split tensile strength of partially replaced RHA concrete to the conventional concrete by considering aspects such as bulk density, specific surface area, practical size, RHA percentage added and discovered that conventional concrete lacks in most levels of replacement to RHA composite concrete, apart from the 7-day strengths of samples with 15 and 20 wt% replacementstrength 21% less than the normal concrete at 3 days that amplified to 4% higher after 1 year.25 The failure component of RHA concrete were investigated by Giaccio et al., and Akinwonmi el al. which revealed that cracks develop under the stresses are higher than the control concrete due to the presence of RHA in concrete.39,54 This can be attributed to the fact that with the increase in the percentage of RHA, the concrete become lighter and stiffer as compared to control concrete hence show more cracks.54

Permeability

The resistance from chloride is a significant factor for the concrete toughness because chlorides will initiate and accelerate the corrosion process of reinforcement in concrete. Madandoust et al., observed that a pozzolanic material enhances the protection from chloride entrance and diminishes the corrosion start time of steel reinforcement25 Le et al., stated that by increasing RHA percentage diminishes permeability of concrete and the lowest permeability value was obtained with 20 % RHA replacement.11 Sensale studied that with 15% RHA replacement in concrete, tolerance to chloride ion infiltration was the best because of voids refining ability of RHA.44 Ganesan et al., concluded from his trial that upto 30% RHA replacement the total charge passing through concrete containing RHA consistently decreases.48 Another researcher Ramasamy studied that with the use of RHA in concrete, chloride ion diffusion increases but yet remain in the ‘‘very low category”. The minimum charge passed was obtained in 15% RHA motar because voids ratio reductions which led to low permeability.55 Hesami et al., conducted a test with varying w/c ratio (0.27, 0.33 and 0.44) on pervious concrete pavement and found that permeability vary with w/c ratio (0.33 < 0.27 < 0.44) and ranges between 0.08-0.48cm/s which is very high to be used as a drain layer.56

Industrial and practical use of RHA.

RHA has been used in various industries of cement, steel, rubber, cosmetic, food etc. Presence of Silica and calcium oxide content govern the suitability of RHA for various applications. Rice husk ash was found to be better supplementary material than silica fumes, fly ash, furnace slag etc. for industrial use. In Steel industry, RHA has been used as an excellent insulator due to its low thermal conductivity, low bulk density etc. RHA is also used for coating molten metal because it does not allow rapid cooling of metal. In cement industry, upto 10% RHA replacement with cement showed remarkable results in the strength for the mixture. Due to high presence of silica in RHA, extraction of silica is quiet economical. This silica can be used as reinforcing agent in rubber industry, it can also be used as cleaning agent in cosmetic industry and anti cracking RHA mixed with cement/lime can be used as a stabilizing agent for soil as it 57,58 agent in food industry.improve the index properties and particle size distribution of soil.59,60

Conclusion

As per the literature review, the following closures are initiated:

- As the percentage of rice husk ash (RHA) increases in the mix, there is decrease in the workability due to which good superplasticizer is mandatory to achieve the required workability. considerable

- The compressive and tensile strength of the mix increase with the addition in the RHA percentage, whereas 20% RHA replacement could be considered optimal.

- As RHA percentage increases in the concrete, chloride ion penetration and permeability decreases because of voids refining ability of RHA.

- emission can 2With the use of RHA in concrete, problems like resources depletion, solid waste disposal andCObe

- emission from rice husk burning is 10% which is little as 2decrease to a greater extent due to CO compare to CO2 emission from cement manufacturing.61

- The above facts concluded that rice husk ash (RHA) is a great substitution component which can be used in concrete yet further investigation for the utilization of rice husk ash (RHA) in pervious concrete can be carried out.

Acknowledgments

This review was carried out and supported by the authors of this paper. Authors are thankful to PAU, Ludhiana resources and one of the author D S Aulakh would like to thank colleagues and staff of CGCTC, Mohali & Mandeep Kaur for their consistent support and valuable suggestions during the work.

References

- Chungsangunsit T, Gheewala S H and Patumsawad S. Emission assessment of rice husk combustion for power production. Int J Energy and Env Engg. 2009;3(5):625-630.

- Roy A. Soil stabilization using Rice husk ash and cement. Int J Civil Engg Res. 2014;5(1):49-54

- Akinyele J O, Salim R W, Oikelome K O and Olateju O T (2015) The use of rice husk ash as a stabilizing agent in lateritic clay soil. Int J Civil and Env Engg. 2016;9(11):1410-1414.

- Bhusari S. Industrial application of rice husk ash as a insulating material: A solution for reduction in land pollution. Int J of Adv Engg Tech. 2016;8(1):552-553.

- Mistry B. Properties and industrial applications of rice husk. Int J Engg Sci and Computing. 2016;16(10):2677-2679.

- Hesami S, Ahmadi S and Nematzadeh M. Effects of rice husk as and fibers on the mechanical properties of pervious concrete pavement. Constr Build Mater. 2014;53:680-691.

CrossRef - Ramasamy R. Compressive strength and durability properties of rice husk ash concrete. J Civil Eng. 2011;16: 93–102.

- Akinwonmi, Samuel A and Emmanuel. Fracture behavior of concrete with rice husk ash replacement under uniaxial compressive load. Res J Engg and Applied Sci. 2013;2(2):132-136.

- Saraswathy V and Song H W. Corrosion performance of rice husk ash blended concrete. Constr Build Mater. 2007;21:1779–1784.

CrossRef - Kulkarni M S, Mirgal P G, Bodhale P P and Tande S N. Effect of rice husk on properties of concrete. J Civil Engg and Env Tech. 2014;1(1):266-29.

- Gastaldini A L G, Isaia G C, Gomes N S and Sperb J E K. Chloride penetration and carbonation in concrete with rice husk ash and chemical activators. Cem Concr Comp. 2007;29:176–180.

CrossRef - Alex J, Dhanalakshmi J and Ambedkar B. Experimental investigation on rice husk ash as replacement on concrete production. Constr Build Mat. 2016;127: 353-362

CrossRef - Muthadhi A and Kothandaraman S. Experimental Investigations of Performance Characteristics of Rice Husk Ash–Blended Concrete. Journal of Materials in Civil Engineering. 2013;25(8):1115-1118.

CrossRef - Ganesan K, Rajagopal K and Thangavel K. Rice husk ash blended cement Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr Build Mat. 2008;22:1675–1683.

CrossRef - Moulick K K. Prospective use of rice husk ash to produce concrete in India. Int J Civil and Env Engg. 2015;9(3):324-329.

- Le H T, Kraus M, Siewert K and Ludwig H M. Effect of macro-meso porous rice husk ash on rheological properties of mortar formulated from self-compacting high performance concrete. Constr Build Mater. 2015;80:225–235.

CrossRef - Nagrale S D, Hajare H and Modak P R. Utilization of rice husk ash. Int J Engg Res and App. 2012;2(4):001-005.

- Sensale G R. Effect of Rice-Husk Ash on Durability of Cementitious Materials. Cem Concr Comp. 2010;32:718–725.

CrossRef - Ferraro R M, Nanni A, Vempati R K and Matta F. Carbon Neutral Off-White Rice Husk Ash as a Partial White Cement Replacement. Mat Civil Engg. 2010;22(10):1078-1083.

CrossRef - Suaiam G and Makul N. Utilization of high volumes of unprocessed lignite-coal fly ash and rice husk ash in self-consolidating concrete. J Clean Prod. 2014;78:184–94.

CrossRef - Salas A, Delvasto S, de Gutierrez R M and Lange D. Comparison of two processes for treating rice husk ash for use in high performance concrete. Cem Concr Res. 2009;39:773–778.

CrossRef - Della V P, Kuhn I and Hotza D. Rice husk ash as an alternate source for active silica production. Mater Lett. 2002;57(4):818–821.

CrossRef - Giaccio G, de Sensale G R and Zerbino R. Failure mechanism of normal and high strength concrete with rice-husk ash. Cem Concr Compos. 2007;29:566–474.

CrossRef - Chao-Lung H, Anh-Tuan B L and Chun-Tsun C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr Build Mater. 2011;25:3768–3772.

CrossRef - Park KB, Kwon S J and Wang X Y. Analysis of the effects of rice husk ash on the hydration of cementitious materials. Constr Build Mater. 2016;105:196–205.

CrossRef - Van V T A, Robler C, Bui D D and Ludwig H M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem Concr Compos. 2014;53:270–278.

CrossRef - Antiohos S K, Papadakis V G and Tsimas S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem Concr Res. 2014;61–62:20–27.

CrossRef - Madandoust R, Ranjbar M M, Moghadam H A andMousavi S Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst Eng. 2011;110:144–152.

CrossRef - Zahedi M, Ramezanianpour A A and Ramezanianpour A M. Evaluation of the mechanical properties and durability of cement mortars containing nano silica and rice husk ash under chloride ion penetration. Constr Build Mater. 2015;78:354–361.

CrossRef - Thomas B S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material – A comprehensive review. J Renewable and Sustainable Energy Reviews. 2017;82(3):3913-3923.

- Zebrino R, Giaacio G and Isaia G C. Concrete incorporating Rice Hush Ash without processing. Constr Build Mat. 2011;25:371-378.

CrossRef - Chao-Lung H, Anh-Tuan B L and Chun-Tsun C. Effect Of Rice Husk Ash on the Strength And Durability Characteristics Of Concrete. Constr Build Mat. 2011;25:3768–3772.

CrossRef - Le H T, Nguyen S T and Ludwig H M. A Study on High Performance Fine-Grained Concrete Containing Rice Husk Ash. Concr Str Mat. 2014;8(4):301–307.

- Chopra D, Siddique R and Kunal. Strength, permeability and microstructure ofself-compacting concrete containing rice husk ash. Biosyst Eng. 2015;130:72–80.

CrossRef - IS 456, Plain and reinforced concrete – code of practice, Bureau of Indian Standard, New Delhi. 2000.

- Bie R, Song X, Liu Q, Ji X and Chen P. Studies on effects of burning conditions and rice husk ash (RHA) blending amount on the mechanical behavior of cement. Cem Concr Compos. 2015;55:162–168.

CrossRef - Madandoust R, Mohammad M and Ahmadi H. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst Eng. 2011;110:144–152.

CrossRef - Zain M F M, Islam M N, Mahmud F and Jamil M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr Build Mater. 2011;25:798–805.

CrossRef - Nair D, Fraaij A, Klaassen A and Kentgens A. A structural investigation relating to the pozzolanic activity of rice husk ashes. Cem Concr Res. 2008;38:861–869.

CrossRef - Siddique R, Singh K, Kunal, Singh M, Corinaldesi V and Rajor A. Properties of bacterial rice husk ash concrete. Constr Build Mater. 2016;121:112–119.

CrossRef - Chindaprasirt P, Rukzon S and Sirivivatnanon V. Resistance to chloride penetration of blended Portland cement mortar containing palm oil fuel ash rice husk ash and fly ash. Constr Build Mater. 2008;22:932–938.

CrossRef - Zerbino R, Giaccio G and Isaia G C. Concrete incorporating rice-husk ash without processing. Constr Build Mater. 2011;25:371–378.

CrossRef - De Sensale G R. Strength development of concrete with rice-husk ash. Cem Concr Compos. 2006;28:158–160.

CrossRef - De Sensale G R. Effect of rice-husk ash on durability of cementitious materials. Cem Concr Compos. 2010;32:718–725.

CrossRef - Safiuddin M, West J S and Soudki K A. Properties of freshly mixed self-consolidating concretes incorporating rice husk ash as a supplementary cementing material. Constr Build Mater. 2012;30:833–842.

CrossRef - Yuzer N, Cinar Z, Akoz F, Biricik H, Gurkan Y Y, Kabay N and Kizilkanat A B. Influence of raw rice husk addition on structure and properties of Concrete. Constr Build Mater. 2013;44:54–62.

CrossRef - Chungsangunsit T, Gheewala S H and Patumsawad S. Environmental assessment of electricity production from rice husk: a case study in Thailand. Int Energy J. 2004;6(1):47-52.

- Chabannes M, Bénézet J C, Clerc L and Garcia-Diaz E. Use of raw rice husk as natural aggregate in a lightweight insulating concrete: an innovative application. Constr Build Mater. 2014;70:428–438.

CrossRef - Bhattacharya S C, Joe M A, Kandhekar Z, Salam P A and Shrestha R M. Greenhouse-gas emission mitigation from the use of agricultural residues: the case of ricehusk.Energy. 1999;24(1):43–59.

CrossRef - Aprianti E S. A huge number of artificial waste materials can be supplementary cementitious material (SCM) for concrete production a review part II. J Clean Prod. 2016;142(4): 4174-4194.

- Le H T, Siewert K and Ludwig H M. Alkali silica reaction in mortar formulated from self-compacting high performance concrete containing rice husk ash. Constr Build Mater. 2015;88:10–19.

CrossRef - Bui D D. Rice Husk Ash as a mineral admixture for high performance concrete [Ph.D.thesis]. The Netherlands: Delft University of Technology. 2001.

- Thomas B S, Gupta R C and Panicker V J. Recycling of waste tire rubber as aggregate in concrete: durability-related performance. J Clean Prod. 2016;112:504–513.

CrossRef - Thomas B S, Gupta R C, Kalla P and Cseteneyi L. Strength, abrasion and permeation characteristics of cement concrete containing discarded rubber fine aggregates. Constr Build Mater. 2014;59:204–212.

CrossRef - Thomas B S, Damare A and Gupta R C. Strength and durability characteristics of copper tailing concrete. Constr Build Mater. 2013;48:894–900.

CrossRef - Mehra P, Gupta R C and Thomas B S. Assessment of durability characteristics of cement concrete containing jarosite. J Clean Prod. 2016;119:59–65.

CrossRef - Mehra P, Gupta R C and Thomas BS. Properties of concrete containing jarosite as a partial substitute for fine aggregates. J Clean Prod. 2016;120:241–248.

CrossRef - Kumar S, Gupta R C, Shrivastava S, Csetenyi L and Thomas B S. Preliminary study on the use of quartz sandstone as a partial replacement of coarse aggregate in concrete based on clay content, morphology and compressive strength of combined gradation Constr Build Mater. 2016;107:103–108.

- Prasittisopin L and Trejo D. Hydration and phase formation of blended cementitious systems incorporating chemically transformed rice husk as. Cem Concr Compos. 2015;59:100–106.

CrossRef - Aprianti E, Shafigh P, Bahri S and Nodeh J. Supplementary cementitious materials origin from agricultural wastes – a review. Constr Build Mater 2015;74:176–87.

CrossRef - Antiohos S K, Tapali J G, Zervaki M, Sousa-coutinho J,Tsimas S and Papadakis V G. Low embodied energy cement containing untreated RHA: A strength development and durability study. Constr Build Mater. 2013;49:455–463.

CrossRef