An Investigation on the Possible Radioactive Contamination of Environment during a Steam-Line Break Accident in a VVER-1200 Nuclear Power Plant

Abid Hossain Khan1

*

, Angkush Kumar Ghosh2

, Angkush Kumar Ghosh2

, Md Sumon Rahman1

, Md Sumon Rahman1

, S M Tazim Ahmed1

, S M Tazim Ahmed1

and C L Karmakar 1

and C L Karmakar 1

Corresponding author Email: abid.khan_ipe@just.edu.bd

DOI: http://dx.doi.org/10.12944/CWE.14.2.14

Copy the following to cite this article:

Khan A. H, Ghosh A. K, Rahman M. S, Ahmed S. M. T, Karmakar C. L. An Investigation on the Possible Radioactive Contamination of Environment during a Steam-Line Break Accident in a VVER-1200 Nuclear Power Plant. Curr World Environ 2019;14(2). DOI:http://dx.doi.org/10.12944/CWE.14.2.14

Copy the following to cite this URL:

Khan A. H, Ghosh A. K, Rahman M. S, Ahmed S. M. T, Karmakar C. L. An Investigation on the Possible Radioactive Contamination of Environment during a Steam-Line Break Accident in a VVER-1200 Nuclear Power Plant. Curr World Environ 2019;14(2). Available from: http://bit.ly/2YTW779

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 02-07-2019 |

|---|---|

| Accepted: | 09-08-2019 |

| Reviewed by: |

Ali Aghababai Beni

Ali Aghababai Beni

|

| Second Review by: |

Vahid Beygzadeh

Vahid Beygzadeh

|

| Final Approval by: | Dr. Gopal Krishan |

Introduction

A major or severe accident in a nuclear power plant is a highly feared event due to its alarming consequences. Contamination of environment by radioactive elements is, perhaps, of more concern rather than on-spot casualties because of the long-term consequences associated with it. The memories of nuclear accidents such as Three Mile Island, Chernobyl, Fukushima Daiichi, etc. are still fresh to thousands of people living all over the world. Three Mile Island accident in 1979 was the first warning to mankind about the sensitivity of a nuclear facility. However, the event was somewhat ignored as it had no record of radioactive emission or loss of life. This ignorance led to Chernobyl nuclear accident in 1986 which caused death of around 31 individuals, or even more.1 People living within a large radius around the accident site were exposed to high dose of radiation due to radioactive emission.2 Thousands of people died due to carcinoma as long-term effect of radiation exposure.3 In order to reduce the entry of radioactive contaminants in the human body, remedial measures are still in place in multiple countries across Europe.4 Even the vast majority of people of Ukraine who were exposed to subclinical radiation dose during the nuclear accident have gone through serious psychological effects. The affected individuals have shown poorer subjective well-being, causing an annual welfare loss of 2-6% of Ukraine’s GDP.5 The results from a 20-years investigation reveal that there has been significant increase in the prevalence of congenital abnormalities in social abortuses, fetuses and newborns.6

Fukushima Daiichi nuclear accident in 2011 was a combination of natural calamity and design insufficiency.7 The radio-nuclides released due to this accident have spread throughout the central-east Japan.8 This has caused radioactive contamination of both seawater9] and soil.10 It is estimated that there have been a total release of 12-37.6 PBq of Cesium-137 and 150-160 PBq of Iodine-131. It is also estimated that maximum human mortality due to the Fukushima Accident is 10000, among which 1500 are cancer mortality.11 The accident has also caused serious psychological problems among the people who were evacuated from the accident zone.12

In order to avoid situations like these, precautions are to be taken to avoid a nuclear accident that may result in radioactive contamination of the environment. International Atomic Energy Agency (IAEA) has established multiple safety fundamentals and safety principles to prevent severe accidents.13 The newly developed Gen-III and III+ nuclear power plants have different active and passive safety features to ensure safety of human life as well as environment. VVER-1200 is a Gen-III+ pressurized water type nuclear power reactor. It has been designed in such a manner that the radioactive elements are confined within the system in case an accident occurs, preventing radioactive contamination14 It also has five levels of safety barriers for preventing release of radioactive materials to the atmosphere during a severe accident. Nevertheless, different unlikely situations must be pre-investigated before the plant becomes operational in order to promote emergency preparedness as well as avoidance of uncontrollable accident.

Steam-line break accident followed by SCRAM (Safety Control Rod Axe Man) is one type of Design Based Accident (DBA). This type of accident may occur due to pressure buildup inside the pipeline. Since steam is the secondary coolant in a Pressurized Water Reactor (PWR) based nuclear power plant, steam-line break accident may also be considered as a variation of Loss of Coolant Accident (LOCA). There have been numerous studies on the effect of steam-line break accident on the transient response of a nuclear power plant. The response varies with the type of reactor used in the power plant. Lim et al., have assessed the performance of passive safety systems for a main steam-line break accident15 Pavlova et al., have investigated steam-line break accident for VVER-1000 type nuclear power plant under full load condition16 Shawxin et al., have studied the transient response of a high-power passive reactor during a steam-line break accident17 Kliem et al., have tested the performance NURESIM platform for analyzing main steam-line break accident of a pressurized water reactor18 Kang et al., have studied main steam-line break accident for an advanced pressurized water reactor.19 Alzaben et al., have analyzed steam-line break accident for a generic SMART-plant with boron-free core20

From the above literature study, it is evident that there are multiple options for analyzing a steam-line break accident. One of the most common accident simulators for nuclear power plants is Personal Computer Transient Analyzer (PCTRAN). Numerous studies have been conducted using PCTRAN to simulate a variety of accident conditions. Ibrahim et al., have conducted a study on the possible ways of simulating the safety and transient responses of a pressurized water reactor using PCTRAN21 Hadad and Esmaeili-Sanjavanmareh have analyzed large break loss of coolant accident for a VVER-1000 type nuclear power plant22 Chiang et al., have combined a number of other nuclear thermal hydraulic codes with PCTRAN to simulate Fukushima-like accident for Chinshan BWR/4 NPP23 Po has shown the use of PCTRAN for simulation of Indonesian conceptual HTR reactor24 Mollah has demonstrated the use of PCTRAN as an education tool for simulation of a pressurized water reactor25 Saha et al., have simulated the steam generator tube rupture accident for a VVER-1200 nuclear power plant26 Fyzaet al., have studied the transient response of VVER-1200 plant parameters during a loss of coolant accident27 There have been other similar studies which have used PCTRAN as a simulation tool for analyzing different accident scenarios for different nuclear power reactors. However, a study on the steam-line break accident of a VVER-1200 based nuclear power plant is yet to be conducted using PCTRAN.

In this work, the transient response of a VVER-1200 based nuclear power plant during a steam-line break accident has been investigated using PCTRAN. A break of 1000 cm2 size in the main steam-line has been considered in this study. It has also been assumed that off-site power supply is unavailable during the accident. The possibility of radioactive contamination of surrounding environment has been investigated afterwards on the basis of the simulation results.

Methodology

In this simulation-based study, the possibility of system failure of a VVER-1200 based nuclear power plant and subsequent contamination of environment by radioactive materials has been investigated during a steam-line break accident. Personal Computer Transient Analyzer (PCTRAN), developed by Micro Simulation Technology Inc., has been used to obtain response of plant safety parameters for this purpose. The PCTRAN module for VVER-1200 is shown in Figure 1.

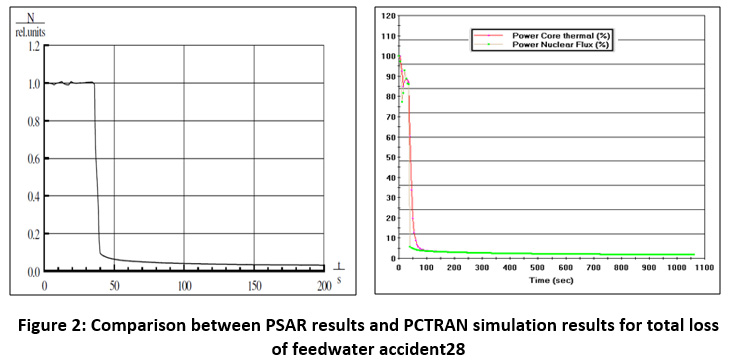

Since VVER-1200 is one of the latest models of pressurized water reactors, very few existing nuclear power plant have been able to complete installation and commissioning of this reactor. As a result, real-time experimental data for most of the accidental scenarios are yet not available. From the Preliminary Safety Assessment Reports (PSARs) and Final Safety Assessment Reports (FSARs), data for limited number of accident types can be obtained. However, some of the accident types are somewhat comparable. For example, total loss of feedwater accident may be compared to steam-line break accident. This is because of the fact that both are initiated in the secondary coolant circuit of the nuclear power plant. feedwater supply line may be considered as the “cold leg” of the secondary coolant circuit while steam supply line may be considered as the “hot leg” of the same. As a result, the response of the plant safety systems for loss of feedwater accident should be, to some extent, similar to that of steam-line break accident. Similarly, if a simulation tool is capable of predicting the transient response of a nuclear power plant during a loss of feedwater accident, it should be capable of predicting the transient response for steam-line break accident too. Figure 2 shows a comparison between the experimental results (core thermal power) obtained from the PSAR of a VVER-1200 based nuclear power plant (Novovoronezh NPP-II) with the results obtained from PCTRAN simulation. From Figure 2, it may be observed that the results are almost identical for both cases. As a result, it may be opined that PCTRAN is capable of simulating loss of feedwater accident with acceptable accuracy, and the same should be for steam-line break accident.

|

Figure 1: PCTRAN console for VVER-1200 type nuclear power plant. Click here to view Figure |

|

Figure 2: Comparison between PSAR results and PCTRAN simulation results for total loss of feedwater accident28 Click here to view Figure |

In order to generate the transient response data of the nuclear power plant, a demo version of PCTRAN has been used. As a result, the transient response of the plant systems may be obtained for not more than 300 seconds. However, the available simulation time is sufficient for the study since the plant safety systems for most Gen-III+ nuclear power plants usually respond within 50 seconds time from accident initiation. Nevertheless, the time has been counted from the beginning of the accident initiation so that maximum possible transient response data may be obtained for accident condition.

A break of 1000 cm2 in the main steam-line of the secondary coolant circuit has been considered in this study. A break size greater than or equal to 1000 cm2 is called a “Large-Break”29 Large break may result in rapid removal of coolant from the system and thus result in catastrophic events. As a result, it is one of the most feared situations. Since steam-line break accident is essentially a Loss of Coolant Accident (LOCA), 1000 cm2 break size should correspond to a Large Break Loss of Coolant Accident (LBLOCA). LBLOCA has been the responsible for a number of serious nuclear accidents. Therefore, this break size has been selected for this study. It has also been assumed that there is external AC power supply from grid during the accident in order to account for “worst case scenario”. The simulation results are then analyzed to identify the deviations from nominal operating values (presented in Table 1). Finally, the possibility of system failure due to any of these deviations was investigated to understand whether there is any chance of contamination of the environment by radioactive elements.

Table 1: Plant Nominal Operating Condition30]

|

Plant Parameters |

Operating Value |

|

Core Thermal Power |

3200 MW |

|

Pressure inside Reactor Core Structure |

162.0 bar |

|

Pressure inside Reactor Containment Building |

1.03 bar |

|

Maximum Cladding Temperature |

610.8oC |

|

Maximum Fuel Temperature |

1800oC |

The objective of the study is to investigate the possibility of system failure which may result in contamination of environment. Contamination should not occur theoretically if the radioactive material does not escape from the five safety barriers of VVER-1200 type nuclear power plant. The five barriers are13, 30:

- Fuel pellet: To confine fission products inside fuel element.

- Fuel Cladding: To confine fission products and prevent contamination of primary coolant in case fuel failure occurs

- Pressure Vessel: To confine the fission products if cladding failure occurs.

- Primary Containment Building: To confine the radioactive elements inside the building in case radioactive products escape the coolant circuits.

- Secondary Containment Building: To confine the radioactive elements in case primary containment failure occurs.

The contamination of the environment is possible only if radioactive elements breach through the fifth barrier i.e. secondary containment building. The possible scenarios in which this may happen are:

Scenario 1

In this scenario, failure of fuel element, fuel pellet and pressure vessel has occurred. As a result, the radioactive fission products are released to the reactor building air. This air will get mixed with fission products and may escape to the environment if either the containment buildings fail or the stack monitoring and air filtration system fails.

Scenario 2

In this scenario, the pressure vessel is unharmed. However, failure of both fuel element and fuel cladding has led to direct contact between primary coolant and radioactive fission products. This may lead to sudden increase in radioactivity level of reactor building air around the primary coolant circuit. This radioactive air may escape to the environment if either containment buildings fail or the stack monitoring and air filtration system fails.

Scenario 3

In this scenario, both fuel element and fuel cladding are unharmed. However, failure of pressure vessel has led to release of highly radioactive water to the reactor building air. This may lead to massive increase in radioactivity level of reactor building air. This highly radioactive air may escape to the environment if either containment buildings fail or the stack monitoring and air filtration system fails.

Scenario 4

In this scenario, fuel element, fuel pellet and pressure vessel are all unharmed. However, slightly radioactive air inside the reactor building may escape to the environment if either containment buildings fail or the stack monitoring and air filtration system fails.

Since there are multiple possible ways in which the contamination of surrounding environment may occur, the only way to prevent contamination with absolute certainty is to prevent failure of all of the safety barriers. This may be done by keeping the system parameters within the limiting values presented in Table 2.

Table 2: Safe operating limits for different safety barriers

|

Safety Barrier |

Safe Operating Limit |

|

Fuel Pellet |

Temperature ≤ 2200oC to prevent meltdown31 |

|

Fuel Cladding |

Temperature ≤ 1480 oC to prevent embrittlement31 |

|

Pressure Vessel |

Pressure ≤ 110% of Nominal Value31 |

|

Primary Containment Building |

Pressure ≤ 414 kPa32 |

Here the safe operating limit of secondary containment building is not mentioned since the design value varies from plant to plant. Also, it is better to prevent failure of the first four safety barriers so that the fifth barrier remains in hand as a last resort. In this work, the possibility of failure of any of the four safety barriers has been investigated for a steam-line break accident so that the possible way of contamination of surrounding environment may be identified.

Results and Discussion

In this study, it has been assumed that steam-line break accident was initiated at the beginning of the time count i.e. at 0.5 second time. This has been done in order to utilize the PCTRAN software to its maximum in generating simulation data for accident scenario. As soon as the steam-line break accident is generated, multiple plant safety systems are activated and deactivated in a sequential form to keep the situation under control. The transient report of the plant just after the emergence of the steam-line break is presented in Table 3.

From the transient report, it may be observed that within 22.5 seconds time, SCRAM (Safety Control Rod Axe Man) is initiated to bring all the control rods down instantaneously inside the reactor core. As a result, the reactivity of the core and subsequently of the primary coolant is brought down within seconds. Since the secondary coolant has no direct contact with the primary coolant, rather they are separated by steam generator tube walls, the reactivity of the steam should be much lower than the primary coolant, and it should be lowered further due to SCRAM initiation. And since it is the steam that is being released through the break area, the increase in radioactivity of the air inside the reactor building should not increase significantly from baseline value after SCRAM. Turbine trip has occurred along with SCRAM at 22.5 seconds since SCRAM should bring down power production significantly. As a result, there shouldn’t be sufficient steam supply to the turbine for electric power generation. Turbine bypass valve is opened at 23.0 seconds time to dump steam directly to the condenser.

Table 3: Transient Report for the Accident

|

Time (sec) |

Response of Plant Safety Systems |

|

19.5 |

Main Steam isolation Valve (MSIV) is closed |

|

22.5 |

Reactor SCRAM |

|

Turbine trip |

|

|

23.0 |

Turbine Bypass Valve is opened |

|

28.0 |

Containment spray starts at 1.3 bar pressure |

|

Containment Vent Valve (CVV) is closed |

|

|

30.5 |

Turbine Driven Auxiliary Feedwater (TDAFW) Pumps 1 and 2 are activated |

|

32.5 |

Steam Generator Safety Relief Valve (SRV) is opened |

|

53.0 |

Steam Generator Safety Relief Valve (SRV) is closed |

|

69.0 |

Feed Water Isolation Valves (FWIVs) are closed |

|

91.0 |

Turbine Bypass Valve is closed |

Containment Vent Valve (CVV) is closed at 28.0 seconds time in order to prevent escape of air mixed with radioactive steam to the surrounding atmosphere. As a result, contamination of environment should be prevented. Simultaneously, Containment Spray system is initiated as the pressure inside the reactor primary containment building has risen above 1.3 bar. This pressure buildup is due to the release of steam to containment building air, which results in rise in temperature. Containment spray is activated to keep temperature and thus pressure of air inside containment building under control.

Turbine Driven Auxiliary Feedwater (TDAFW) Pumps are activated at 30.5 seconds in order to maintain feedwater supply inside steam generator, which is necessary for heat removal of primary coolant and thus reactor core. Also, Steam Generator Safety Relief Valve (SRV) is opened at 32.5 seconds time to relieve steam and reduce pressure inside steam generator. However, within 53.0 seconds time, the pressure inside steam generator becomes quite low due to reduced heat supply from primary coolant. Therefore, Safety relief Valves are closed. At 69.0 seconds, Turbine Driven Auxiliary Feedwater (TDAFW)) are closed to cut-off feedwater supply to steam generator as there is negligible heat generation in the core that may be removed by Residual Heat Removal (RHR) systems. Finally, Turbine Bypass Valve is closed at 91.0 seconds as there is almost no steam to bypass to the condenser.

The change in core thermal power with time for the plant is shown in Figure 3. From Figure 3, it may be observed that the maximum core thermal power is just below 105% of the nominal value. However, it is immediately brought down SCRAM is initiated. Within 75 seconds time, reactor core thermal power has dropped below 5% of normal operating value. The decrease is due to the instantaneous insertion of negative reactivity inside the reactor core by control rods, which has resulted in rapid decrease in reactivity and thus in rate of power generation. Therefore, it may be stated that the plant safety systems are capable of keeping power generation within safety limits during a steam-line break accident and overheating of components is unlikely.

|

Figure 3: Change in Core Thermal Power with Time. Click here to view Figure |

The change in peak temperature of fuel pellet and fuel cladding with time is shown in Figure 4. From Figure 4, it may be observed that the peak temperatures of fuel pellet and fuel cladding are recorded to be around 1850oC and 620oC respectively. These values are well within the safety limits specified by IAEA acceptance criteria31 As a result, there is no overheating of either fuel element of cladding material. So, it may be stated that failure of either fuel pellets or fuel cladding should not be observed for steam-line break accident and the possibility of radioactive contamination of environment due to the conditions similar to Scenario 1 and Scenario 2 may be discarded.

|

Figure 4: Change in Peak Fuel and Cladding Temperature with Time. Click here to view Figure |

The change in average temperature of reactor core structure and reactor building air with time is presented in Figure 5. From Figure 5, it may be observed that the average temperature of reactor core structure, i.e. fuel assembly and primary coolant has gone down with time. This is due to the reduction in core thermal power due to SCRAM. However, the temperature of air inside primary containment building has risen above 100oC. If someone is trapped inside the building during the accident, there is a possibility of loss of human life.

|

Figure 5: Change in Average Temperature of Reactor Core Structure and Reactor Building Air with Time. Click here to view Figure |

The change in pressure inside Reactor Core Structure (RCS) or pressure vessel with time is shown in Figure 6. From Figure 6, it may be observed that RCS pressure has at first been maintained steadily for around 22.5 seconds. After that, the pressure inside the system has fallen down. The reason behind this is the active pressure regulation by the pressurizer until the SCRAM is initiated. However, pressurizer has seized to function after SCRAM since there is no need of pressure regulation of the system if there is no electric power generation. As a result, pressure has been brought down rapidly within 120.0 seconds time. Nevertheless, the pressure inside pressure vessel has never crossed the acceptance value of 110% of nominal pressure for Design Based Accident (DBA). So, it may be stated that the integrity of pressure vessel should be unaffected and the possibility of Scenario 3 may also be discarded.

|

Figure 6: Change in Reactor Core Structure Pressure with Time. Click here to view Figure |

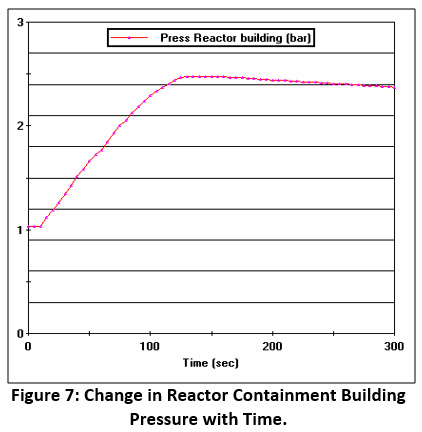

The change in pressure of air inside reactor containment building with time is shown in Figure 7. From Figure 7, it may be observed that pressure has increased for around 120.0 seconds due to release of hot steam to the building air. However, the containment spray system has been able to bring it down afterwards as the rate of steam generation in steam generator has fallen down. An important observation from Figure 6 is that the building air pressure has been kept within 2.5 bar by the plant safety systems. This value is much lower than the design value of 4.14 bar observed in most plants in USA32 Since the safety factors in VVER-1200 is even higher than the previous designs, it may be assumed that containment building should be strong enough to withstand this pressure and failure of containment due to over-pressure should not be encountered for steam-line break accident. As a result, the possibility of encountering Scenario 4 may also be omitted.

|

Figure 7: Change in Reactor Containment Building Pressure with Time. Click here to view Figure |

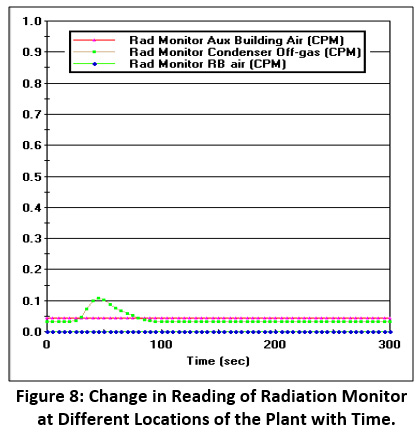

Since Scenario 1 to 4 are unlikely to be encountered for a steam-line break accident in VVER-1200 type nuclear power plant, the only possible way in which contamination of the surrounding environment may occur is by the failure of stack monitoring system. However, if the system air has low amount of radioactivity, the fear of contamination is unjustified. Therefore, the activity of air at different locations needs to be investigated. The change in reading of radiation monitor at different locations of the plant with time is presented in Figure 8. From Figure 8, it may be observed that the activity of air inside the nuclear facility has always been low at almost all locations, much lower than 0.2 CPM (counts per minute). The logical explanation of this is that the air inside the reactor building is in direct contact with steam, which is the secondary coolant of the system. Since steam is only slightly radioactive due to exposure to primary coolant in the steam generator, mixing of steam with air has not increased activity of air significantly. Therefore, it may be stated that even if stack monitoring and air filtration system fails during a steam-line break accident, the contamination of the environment should be insignificant as the plant safety systems should keep the radioactivity of the air inside the nuclear facility low enough.

|

Figure 8: Change in Reading of Radiation Monitor at Different Locations of the Plant with Time. Click here to view Figure |

From the above results, it may be assumed that the plant safety systems of VVER-1200 type nuclear power plants are sufficient to prevent serious radioactive contamination of the environment if a steam-line break accident occurs.

Conclusion

In this work, the possibility of radioactive contamination of environment due to a steam-line break in a VVER-1200 type nuclear power plant accident has been investigated. Personal Computer Transient Analyzer (PCTRAN) has been used for obtaining the transient response of the plant. A break of 1000 cm2 in the main steam-line has been considered. Also, it has been assumed that off-site AC power supply is completely cut-off from the system during the accident.

Results indicate that multiple plant safety systems are sequentially activated and deactivated in order to cope with the situation. SCRAM is initiated within 22.5 seconds time along with turbine trip. Turbine bypass valve is opened at 23.0 seconds and closed at 91.0 seconds time. Containment Vent Valve (CVV) is closed at 28.0 seconds to prevent escape of radioactive air from reactor building to the atmosphere. Also, Containment spray is activated to keep pressure inside containment building within safety limits. Turbine Driven Auxiliary Feedwater (TDAFW) Pumps are activated at 30.5 seconds in order to maintain feedwater supply inside steam generator. Steam Generator Safety Relief Valve (SRV) is opened at 32.5 seconds and closed at 53.0 seconds time.

The peak core thermal power is recorded to be around 105% of the nominal operating value. This is brought down to below 5% within 75.0 seconds. Peak fuel and cladding temperatures are recorded to be around 1850oC and 620oC respectively, which are both within acceptance criteria by IAEA. Temperature inside the primary containment building has reached a value higher than 100oC. However, the pressure inside primary containment building has been kept below 2.5 bar. As a result, it is safe from failure due to pressure buildup. The pressure inside reactor pressure vessel has gradually decreased from 162.0 bar, thus has not crossed the 110% limiting value for Design Based Accident. Therefore, it may be opined that all four safety barriers of VVER-1200 based nuclear power plant are intact. Finally, the activity levels inside the nuclear facility at different locations are well below 0.2 CPM, which is a very insignificant value. Therefore, leakage of air from the nuclear facility to the atmosphere should not cause serious contamination.

The above study has focused only on the safety of a VVER-1200 type nuclear power plant during a steam-line break accident. Other types of power plants may also be studied for similar accident. Also, the break size may be varied to see the response of the plant for other conditions. Finally, this study has assumed that SCRAM was available when the accident occurred. In some unexpected situation, malfunction may lead to unavailability of SCRAM. This type of scenario, also known as Anticipated Transient without SCRAM (ATWS) may also be studied for steam-line break accident.

Nomenclature

|

Abbreviations |

Meaning/ Explanation |

|

ATS |

Anticipated Transient With Scram |

|

ATWS |

Anticipated Transient without Scram |

|

CPM |

Counts Per Minute |

|

CVV |

Containment Vent Valve |

|

DBA |

Design Based Accident |

|

FSAR |

Final Safety Assessment Report |

|

FWIV |

Feed Water Isolation Valves |

|

IAEA |

International Atomic Energy Agency |

|

LOCA |

Loss of Coolant Accident |

|

MSIV |

Main Steam isolation Valve |

|

PCTRAN |

Personal Computer Transient Analyzer |

|

PSAR |

Preliminary Safety Assessment Report |

|

PWR |

Pressurized Water Reactor |

|

RCB |

Reactor Containment Building |

|

RCS |

Reactor Core Structure |

|

SCRAM |

Safety Control Rod Axe Man |

|

SRV |

Safety Relief Valve |

|

TBV |

Turbine Bypass Valve |

|

TDAFW |

Turbine Driven Auxiliary Feedwater |

References

- Highfield, R. How many died because of the Chernobyl disaster? We don’t really know. New Scientist. Article published on April 21, 2011.

- Kortov V, Ustyantsev Y. Chernobyl accident: Causes, consequences and problems of radiation measurements. Radiation Measurements. 2013;55:12-6.

CrossRef - Baverstock K, Williams D. The Chernobyl accident 20 years on: an assessment of the health consequences and the international response. Environmental Health Perspectives. 2006;114(9):1312-7.

CrossRef - Beresford NA, Fesenko S, Konoplev A, Skuterud L, Smith JT, Voigt G. Thirty years after the Chernobyl accident: what lessons have we learnt?. Journal of environmental radioactivity. 2016;157:77-89.

CrossRef - Danzer AM, Danzer N. The long-run consequences of Chernobyl: Evidence on subjective well-being, mental health and welfare. Journal of Public Economics. 2016;135:47-60.

CrossRef - Lazjuk GI, Satow Y. Some Issues of Long-Term Investigations on Genetic Consequences by the Chernobyl Accident. http://www. rri. kyoto-u. ac. jp/NSRG/reports/kr139/pdf/lazjuk. pdf. 2016.

- Khan AH, Hasan S, Sarkar MAR. Analysis of Possible Causes of Fukushima Disaster. International Journal of Nuclear and Quantum Engineering. 2018;12(2):53-8.

- Kinoshita N, Sueki K, Sasa K, Kitagawa JI, Ikarashi S, Nishimura T, Wong YS, Satou Y, Handa K, Takahashi T, Sato M. Assessment of individual radionuclide distributions from the Fukushima nuclear accident covering central-east Japan. Proceedings of the National Academy of Sciences. 2011;108(49):19526-9.

CrossRef - Buesseler K, Aoyama M, Fukasawa M. Impacts of the Fukushima nuclear power plants on marine radioactivity. Environmental Science & Technology. 2011;45(23):9931-5.

CrossRef - Yasunari TJ, Stohl A, Hayano RS, Burkhart JF, Eckhardt S, Yasunari T. Cesium-137 deposition and contamination of Japanese soils due to the Fukushima nuclear accident. Proceedings of the National Academy of Sciences. 2011;108(49):19530-4.

CrossRef - Aliyu AS, Evangeliou N, Mousseau TA, Wu J, Ramli AT. An overview of current knowledge concerning the health and environmental consequences of the Fukushima Daiichi Nuclear Power Plant (FDNPP) accident. Environment International. 2015 Dec 1;85:213-28.

CrossRef - Hasegawa A, Ohira T, Maeda M, Yasumura S, Tanigawa K. Emergency responses and health consequences after the Fukushima accident; evacuation and relocation. Clinical Oncology. 2016;28(4):237-44.

CrossRef - Principles IF. Safety Fundamentals.IAEA Safety Standards Series SF-1, International Atomic Energy Agency, Vienna, Austria. 2006.

- Asmolov VG, Gusev IN, Kazanskiy VR, Povarov VP, Statsura DB. New generation first-of-the kind unit–VVER-1200 design features. Nuclear Energy and Technology. 2017;3(4):260-9.

CrossRef - Lim J, Choi SW, Yang J, Lee DY, Rassame S, Hibiki T, Ishii M. Assessment of passive safety system performance under main steam line break accident. Annals of Nuclear Energy. 2014;64:287-94.

CrossRef - Pavlova M, Andreeva M, Groudev P. Steam Line Break investigation at full power reactor for VVER-1000/V320. Nuclear Engineering and Design. 2015;285:65-74.

CrossRef - Shaoxin Z, Wei S, Jianping J, Jieru A, Chunming Z. Transient Analyses of Main Steam Line Break Accident for High-Power Passive Reactor. Proceedings of the 20th Pacific Basin Nuclear Conference. 2016;3:365-73.

CrossRef - Kliem S, Kozmenkov Y, Hadek J, Perin Y, Fouquet F, Bernard F, Sargeni A, Cuervo D, Sabater A, Sánchez-Cervera S, Garcia-Herranz N. Testing the NURESIM platform on a PWR main steam line break benchmark. Nuclear Engineering and Design. 2017;321:8-25.

CrossRef - Kang KH, Park YS, Bae BU, Kim JR, Choi NH, Choi KY. Code assessment of ATLAS integral effect test simulating main steam-line break accident of an advanced pressurized water reactor. Journal of Nuclear Science and Technology. 2018;55(1):104-12.

CrossRef - Alzaben Y, Sanchez-Espinoza VH, Stieglitz R. Analysis of a steam line break accident of a generic SMART-plant with a boron-free core using the coupled code TRACE/PARCS. Nuclear Engineering and Design. 2019;350:33-42.

CrossRef - Ibrahim SJ, Ewim DR, Edeoja OA. Simulation of Safety and Transient Analysis of a Pressurized Water Reactor using the Personal Computer Transient Analyzer. Leonardo Electronic Journal of Practices and Technologies. 2013;22:93-105.

- Hadad K, Esmaeili-Sanjavanmareh M. PCTRAN enhancement for large break loss of coolant accident concurrent with loss of offsite power in VVER-1000 simulation. Kerntechnik. 2017;82(2):176-83.

CrossRef - Chiang Y, Chen SW, Wang JR, Wang TY, Chen HC, Hsu WS, Chiang SC, Shih C. Code crosswalk of Fukushima-like simulations for Chinshan BWR/4 NPP using MELCOR2. 1/SNAP, TRACE/SNAP, PCTRAN and MAAP5. 03. Nuclear Engineering and Design. 2017;325:12-24.

CrossRef - Po LC. A PC-based high temperature gas reactor simulator for Indonesian conceptual HTR reactor basic training. Journal of Physics: Conference Series. 2018;1013(1); 012183.

CrossRef - Mollah AS. PCTRAN: Education Tool for Simulation of Safety and Transient Analysis of a Pressurized Water Reactor. International Journal of Integrated Sciences and Technology. 2018;3:1-10

- Saha A, Fyza N, Hossain A, Sarkar MR. Simulation of tube rupture in steam generator and transient analysis of VVER-1200 using PCTRAN. Energy Procedia. 2019;160:162-9.

CrossRef - Fyza N, Hossain A, Sarkar R. Analysis of the thermal-hydraulic parameters of VVER-1200 due to loss of coolant accident concurrent with loss of offsite power. Energy Procedia. 2019;160:155-61.

CrossRef - PCTRAN VVER-1200 Manual. 2012.

- Joyce M. Nuclear Engineering: A Conceptual Introduction to Nuclear Power. Butterworth-Heinemann. 2017.

- Advanced Reactors Information System (ARIS). Status Report 108- VVER-1200 (V-491).2006

- Accident Analysis for Nuclear Power Plants with Pressurized Water Reactors, IAEA Safety Report Series No.3.2003, International Atomic Energy Agency, Vienna, Austria. 2003.

- Hossain M, Khan AH, Sarkar MAR. A Numerical Approach for Designing the Primary Containment Building of a Pressurized Water Reactor. Transactions of American Nuclear Society, 2018;118:809-810.