Institution Based Solar Steam Cooking Systems in India

DOI: http://dx.doi.org/10.12944/CWE.15.2.07

Copy the following to cite this article:

Aggarwal R. K. Institution Based Solar Steam Cooking Systems in India. Curr World Environ 2020; 15(2). DOI:http://dx.doi.org/10.12944/CWE.15.2.07

Copy the following to cite this URL:

Aggarwal R. K. Institution Based Solar Steam Cooking Systems in India. Curr World Environ 2020; 15(2). Available from: https://bit.ly/3i67ZYY

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 26-05-2020 |

|---|---|

| Accepted: | 27-07-2020 |

| Reviewed by: |

Issa Ahmed Abed

Issa Ahmed Abed

|

| Second Review by: |

Diane Palmer

Diane Palmer

|

| Final Approval by: | Dr Gopal Krishan |

Introduction

Approximately 27 million rural population rely on biomass for cooking.1 Fuelwood, Liquid Petroleum Gas (LPG) and biomass wastes are being used for community cooking. Traditional fuels being used, release hazardous smoke. Use of traditional inefficient biomass burning cookstove causes poor air quality, affecting human health, deteriorating forest eco system, global warming and climate change. According to WHO, 1.5 million people die annually worldwide due to indoor air pollution.2-9

Renewable energy share is 12% of a total 200 GW of electricity produced in India. Due to rise in population, economic development, and changing lifestyles electricity requirement in India has been increasing despite of continuous rise in capacity.

India receives solar radiations ranging 3.0–6.5 kWhm-2 per day.10 Solar radiations can be utilized for cooking, heating, lighting and other applications. With the technology advancement and economical viability the SPV, SWH, solar desalination, solar drying and steam cooking system are popular practical applications of solar energy. Solar steam cooking (SSC) system is solar energy based technology used to cook food for large number of persons. In solar steam cooking system, the solar radiation falls on a solar concentrator, water become steam at high T&P, which is taken to the kitchen using insulated pipes.11-14 The solar concentrators being propagated in the country are single axis TFFS dish and dual axis TFP (ARUN© Dish).(15,16)

A solar cooking system of community size consists of number of automatically TPRs (Scheffler dish), assembled in series and parallel combinations to generate steam for cooking food for thousands of people twice a day without polluting environment with in short period of time.

In SSC, temperature of 350-4000C is generally achieved. A 7m2 sized solar dish can cook the food for 50 people and large sized dish (16m2) can prepare meal for more than 50–100 person.17 Traditional food such as chapattis, boiling or frying rice, vegetables, cereal, pulses, regional dishes etc. can be prepared. The JNNSM aimed to support solar based heating system that has set the ambitious target for domestic and industrial applications. The MNRE will install 20 million m2 of collector/reflector area during phase III (2017-2022) under the mission.18 Scheffler type dish is used as concentrator for cooking.19-21 Because of simple design, the industrial & maintenance expenditure of a Scheffler dish is cheaper than the other concentrators.15,22-23

Components of Solar Steam Cooking System

|

Figure1: The various components of solar steam cooking system are presented in this section. |

Design and Dimensions of Solar Steam Cooking System

The design specifications of various components of SSC have been presented in this section.

Scheffler Dish

Wolfgang Scheffler initially developed Scheffler reflector in 1986 which is a parabolic dish in which single axis tracking is provided to move along with sun. Scheffler reflector has a fixed focal point, which makes cooking easily and temperatures, rises to 450° - 650°C. The Scheffler reflector system installed at Scheffler reflector system installed at Prajapita Brahma Kumaris Ishwariya Vishwa Vidhyalaya, Om Shanti Bhawan, Madhuban, Mount Abu Rajasthan, India in 1999 has capacity to cook food for 35,000 persons daily was a largest in the world. The Scheffler dish concentrates solar beam at concentration ratio of 100 at absorber to get steam.25

Dimensions

Diameter: 1 m

Reflector Material: Acrylic

Steam pressure: 10 bar

Steam temperature: 1800C

Absorber

The absorber is used to receive the concentrated solar radiation to convert water into steam.26

(a) Specifications

Capacity: 2 kg

Material: Aluminum

(b) Design Calculation:

Steam jacketed utensils

Initial temperature of rice, T1: 200C

Final temperature of rice, T2: 1000C

Steam Jacketed Utensils

The steam from absorber is carried to kitchen using insulated pipe 27.

(a) Specifications

Capacity: 2 kg

Material: Steel

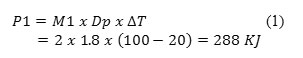

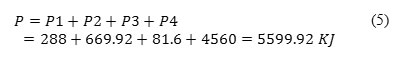

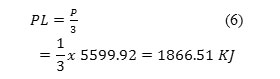

(b) Energy Required in Solar Collector Energy for Cooking Rice:

M1: 2Kg

Dp: 1.8 KJ(Kg oC) -1

Estimation of the useful energy required for cooking has been reported by.28-31

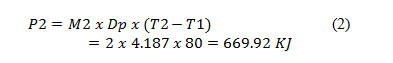

Energy Requirement for Water Boiling

M2: 2 Kg

Specific heat of Water: 4.187 KJ(Kg oC) -1

Water temperature initially, T1: 20 oC

Final temperature of water, T2: 100 oC

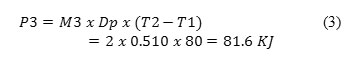

Energy Required for Cooking Pot

M3: 2 Kg

Specific heat capacity of Stainless steel: 0.510 KJ(Kg oC) -1

Initial temperature, T1: 20 oC

Final temperature, T2: 100 o C

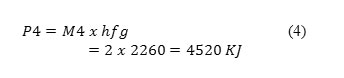

Energy for Water Vaporization

Mass of water (M4): 2 Kg

hfg = 2260 KJKg-1

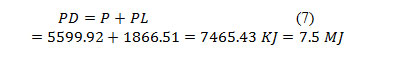

Total Energy

The one-third of the required energy for cooking get lost

Loss

Total Energy Required for Cooking 2 Kg of Rice

Collector Area

Energy for cooking rice (2kg) = 7.5 MJ

Hourly GSR = 1.583MJm-2

Cooking time

Time required = 7.5/ 1.583 = 4.74 hours.

Collector area = 6 m2

Cooking time with 6 m2 = 7.5/ (6 × 1.583) = 0.79 hours

Installation of Solar Cooking System

Due to high temperature achieved in the system, the cooking time has reduced by 45 minutes than conventional solar cookers.32 The suitability of solar steam cooking in institute’s kitchen with SR was found by More.33 Four dishes of 16 m2 SR were used to cook food for 500 persons daily by generating steam of 230 kgd-1 resulted in saving of 19 kg of LPG/day. A SSC system was installed at automobile department, Nehru College of Engineering and Research Centre, Kerala. The maximum water temperature at the outlet was 140.20 C by using aluminum sheet reflector. GI sheet is not better option to cook food.34

A SSC system was installed at Sai Baba Shridi, Ahmednagar, Maharashtra for cooking 20,000 people per day during 2009. The system is generating 3,500 kg of steam daily, which resulted in saving of 100,000 kg of cooking gas.35 The system cost was about Rs 133 lakh out of which 43% was paid by the government. TTD, Andhra Pradesh has set up a SSC system for preparing meal for 15,000 persons daily. The system generates around 4,000 kg of steam d-1 at 1800C and ten kgcm-2 that sufficient to prepare food two time for nearly15,000 devotees. It was modular and consisted of 106 automatic TPC arranged in series & parallel combination, each of 9.2 m2 reflector area. The all concentrators were attached to a central steam piping connected to the kitchen. The system helped in saving of 1,18,000 liters of diesel annually amounting Rs. 0.23 million. The system cost was about Rs. 11crore with 5.5 crore paid by MNRE, rest was paid by the TTD trust.36 A SSC system was installed at Golden Temple, Amritsar in 2017 for cooking food for 50,000 persons costing Rs. 17.25 million, which significantly reduced daily consumption of 600 LPG cylinders and 30,000 kg of firewood.37

A solar steam cooking system was installed at Shantivan Complex, Gyan Sarovar Complex and Madhuban campuses; Mount Abu in 1988 in collaboration with Switzerland based Wolfgang Scheffler, along with Brahma Kumaris World Spiritual University (BKWSU’s) for catering meal for 35,000 persons.38 The roof consisted of 84 parabolic concentrators of 96m² size. The temperature reached to 500ºC at its focal point. It generates 3500 Kg of steam daily and cooking time for 50 kg of rice was 12-14 minutes. It saveda bout 200 liters of diesel, 1.2 tons of CO2 daily and saved 184 kg of LPG every day (ENVIS Center on Human Settlement’s Hosted by School of Planning and Architecture, Delhi). Sarkari Kumar Chhatralay, Vyra has installed the Parabolic Dishes based Concentrated Solar Cooking System consisted of 4 concentrators of 16 m2 each of collector area. The system was commissioned in 2011 costing Rs. 8 Lakh out of which Gujarat State Tribal Development Residential Educational Institutions Society (GSTDREIS) has granted Rs. 5.6 Lakh & MNRE granted of Rs. 2.4 Lakh as subsidy. The system is cooking 20 kg of rice, 10 kg of Dal and 10 kg of vegetables daily resulted in saving 120 of LPG/year. The Uttrakhand Renewable Energy Development Agency, Department of Renewable Energy GOI, Uttrakhand has installed solar steam cooking system at various locations which has been summarized in Table 1.

Table 1: Details of Solar Steam Cooking Systems installed/being installed in Uttarakhand39

|

S. No. |

Name of Site/Beneficiary |

Capacity (sqm.) |

No. of Systems |

Year |

|

1 |

Shantikunj, Haridwar for cooking of food to 1000 persons |

160 |

1 |

2009-2010 |

|

2 |

GauTirth Ashram, Koteshwarpuram, Tehri for distillation of cow urine for medicinal use |

16 |

1 |

2011-12 |

|

3 |

Jindal Refinery, Kashipur for 30,000 ltr. Of water heating to feed in boiler |

480 |

1 |

2011-12 |

|

4 |

Indian Institute of Technology (IIT), Roorkee for cooking food in hostels |

976 |

9 |

2012-13 |

|

5 |

Unique Hotel and Restaurant Pvt. Ltd., 97 Rajpur Road, Dehradun for water heating |

80 |

1 |

2013-14 |

|

6 |

Swami Ramtirth Mission, Rajpur Road, Dehradun for cooking |

16 |

1 |

2013-14 |

|

7 |

Rajiv Gandhi NavodayaVidyalaya, Shikarpur, Haridwar for cooking of food for 300 children |

64 |

1 |

2014-15 |

|

8 |

Rajiv Gandhi NavodayaVidyalaya, Chaunoliya, Almora for cooking of food for 300 children |

64 |

1 |

2014-15 |

|

9 |

Eco Gole Girls International School, Dehradoon |

256 |

1 |

2015-16 |

|

10 |

M/s TTK Prestige Ltd., Roorkee. Non imaging concentrator |

195 |

1 |

2015-16 |

Discussion

The study revealed that solar steam cooking system can be installed at community level for energy conservation in various institutions. It will help in reduction of CO2 for mitigating climate change also. It reduces the consumption of LPG thus saving the fuel bill of the institutions. It will also reduce the cooking time and labour for cleaning of utensils as the washing of utensils is done using steam only. On the basis of successful functioning of solar steam cooking system at various locations, this university intends to install the similar system for 1500 students under a common mess for boys and girls.

Conclusions

It is evident from the above discussion that solar steam cooking system is suitable for cooking food for 50 to 50,000 persons thus, reducing the consumption of conventional fuels. It can also be used for water heating also. It will also reduce the cooking time without detouring indoor air quality. It will result in reducing the emission of greenhouse gases and mitigating the climate change. The number of LPG cylinder saved can be utilized for providing LPG to low income group families.

List of Acronym

|

GW |

Giga Watt |

|

SPV |

Solar photovoltaic |

|

SWH |

Solar water heating system |

|

CST |

Concentrated Solar Thermal |

|

GI |

Galvanized Iron |

|

kJ |

Kilo Joule |

|

DT |

Temperature difference |

|

JNNSM |

Jawaharlal Nehru National Solar Mission |

|

MNRE |

Ministry of New and Renewable Energy |

|

T&P |

Temperature and pressure |

|

TFFC |

Tracked fixed focus Scheffler |

|

TFP |

Tracked Fresnel paraboloid |

|

TPRs |

Tracked paraboloidal reflectors |

|

TPC |

Tracked parabolic concentrators |

|

M1 |

Mass of rice |

|

Dp |

Specific heat of rice |

|

M2 |

Mass of water |

|

M3 |

Mass of steel |

|

hfg |

Latent heat of vaporization of water |

|

GSR |

Global solar radiation |

|

SR |

Scheffler reflector |

|

TTD |

Tirumala Tirupathi Devasthanam |

Acknowledgement

The facilities provided by department of Environmental Science, Dr Y S Parmar University of Horticulture & Forestry, Nauni are highly acknowledged.

Conflict of Interest

There is no conflict of interest of this paper.

References

- IEA. 2011. World Energy outlook, Energy for all.

- Iqbal, J.M., Cecil, F., Ahmad, K., Iqbal, M., Mushtaq, M., Naeem, M.A., Bokhari, T.H. 2013. Kinetic study of Cr (III) and Cr (VI) biosorption using Rosa damascenaphytomass: a rose waste biomass. Asian Journal of Chemistry, 25, 2099.

- Amadi, S., Ukpaka, C. 2015. Role of molecular diffusion in the recovery of water flood residual oil. Chemistry International, 2, 103-114.

- Iqbal, M., Bhatti, I.A. 2015. Gamma radiation/H 2 O 2 treatment of a non ylphenoleth- oxylates: degradation, cytotoxicity, and mutagenicity evaluation. Journal of hazardous materials, 299, 351-360.

- Iqbal, M., Khera, R.A. 2015. Adsorption of copper and lead in single and binary metal system onto Fumariaindica biomass. Chemistry International, 1, 157b-163b. j.rser.2017.03.044.

- Iqbal, M., Abbas, M., Arshad, M., Hussain, T., Khan, A.U., Masood, N., Tahir, M.A., Hussain, S.M., Bokhari, T.H., Khera, R.A. 2015. Gamma radiation treatment for reducing cytotoxicity and mutagenicity in industrial wastewater. Pol. J. Environ. Stud, 24, 2745-2750.

- Babarinde, A., Ogundipe, Kemi, Sangosanya, K.T., Akintola, B.D., Elizabeth Hassan, A.-O. 2016. Comparative study on the biosorption of Pb(II), Cd(II) and Zn(II) using Lemon grass (Cymbopogoncitratus): kinetics, isotherms and thermodynamics. Chemistry International, 2, 89-102.

- Babarinde, A., Onyiaocha, G.O. 2016. Equilibrium sorption of divalent metal ions onto groundnut (Arachishypogaea) shell: kinetics, isotherm and thermodynamics. Chemistry International, 2, 37-46.

- Iqbal, M. 2016. Viciafaba bioassay for environmental toxicity monitoring: a review. Chemosphere, 144, 785-802.

- Cassie F. Quigley Dani Herro Faiza M Jamil. 2017. Developing a Conceptual Model of Steam Teaching Practices. School science and mathematics, 117(1-2):1-12.

- Ummadisingu A, M.S. Soni. 2011. Concentrating solar power - technology, potential and policy in India. Renew. Sustain. Energy Rev, 15: 5169-5175.

- Naik H, P. Baredar, A. Kumar. 2017. Medium temperature application of concentrated solar thermal technology: Indian perspective, Renew. Sustain. Energy Rev, 76: 369-378.

- Jayasimha B. 2006. Application of Scheffler reflectors for process industry, in: Int. Sol. Cooker Conf., Granada, Spain, 1-2.

- Kumar A, O. Prakash, A.K. Kaviti. 2017. A comprehensive review of Scheffler solar collector. Renew. Sustain. Energy Rev. https://doi.org/10.1016/.

- CSH India. 2014. Scheffler Dish Operations and Maintenance Manual. UNDP-GEF Concentrated Solar Thermal Heat (CSH) Project, Ministry of New and Renewable Energy, Government of India, New Delhi, India.

- CSH India. 2016. Fresnel Reflector Based Dish. UNDP-GEF Concentrated Solar Thermal Heat (CSH) Project, Ministry of New and Renewable Energy, Government of India, New Delhi, India.http://www.cshindia.in/images/pdf/ Fresnel Reflector Based Dish.pdf.

- Solar cooker. Energetica India. 2016. file:///C:/Users/EVS/Downloads/27vsCM5wUN89ijnVUkKPWOQldwoccOLSK7NH50cG7ZofBzmJE0YUj.pdf downloaded on 7th July 2020.

- https://cleanleap.com/2-overview-indian-solar-energy-sector/21-jawaharlal-nehru-national-solar-mission downloaded on 7th July, 2020.

- Kalogirou S A. 2004. Solar thermal collectors and applications, Prog. Energy Combust. Sci, 30: 231-295.

- Scheffler W. 2006. Introduction to the revolutionary design of Scheffler reflectors, in: Sol. Cookers Food Process. Int. Conf., 12-16 July 2006, Granada, Spain.

- Dang A. 1986. Concentrators: a review. Energy Convers. Manag, 26: 11-26.

- CSH India. 2015. Material and component specifications: fixed focus automatically tracked elliptical dish (Scheffler), in: UNDP-GEF Concentrated Solar Thermal Heat (CSH) Project, Ministry of New and Renewable Energy, Government of India, New Delhi, India: 1-31.

- Indora S., and Kandpal, T. C. 2018. Financial Appraisal of Using Scheffler Dish for Steam Based Institutional Solar Cooking in India. Renewable Energy, 35,1400-1411.

- Prasanna U R. 2010. Modeling, optimization and design of solar thermal energy transport system for hybrid cooking application. Faculty of Engineering, IIS, Bangalore. Ph D thesis.

- Abdallah E, Mohammed Al_Soud, Ali Akaylehand Salah Abdallah. 2010. “Cylindrical Solar Cooker with Automatic Two Axes Sun Tracking System”, Jordan Journal of Mechanical and Industrial Engineering, 477-486.

- MeenakshiSundaram, Arulkumaran and William Christraj. 2012. Experimental Analysis of Non Tracking Solar Parabolic Dish Concentrating System for Steam Generation, EJ Engineering Journal, 53-60.

- Patil M Rand P S Patil. 2012. Techno-economic assessment of solar steam cooking system, World Journal of Science and Technology, 12-14.

- Ravindranath N H, J. Ramakrishna. 1997. Energy options for cooking in India, Energy Pol, 25, 63-75.

- Sinha C S and T.C. Kandpal. 1991. Optimal mix of technologies in rural India: the cooking sector, Int. J. Energy Res, 15, 85-100.

- Wijayatunga, P D C R.A. Attalage. 2002. Analysis of household cooking energy de- mand and its environmental impact in Sri Lanka, Energy Convers. Mana,. 43, 2213-2223.

- Ang B W. 1986. A method for estimating non-commercial energy consumption in the household sector of developing countries, Energy, 11, 315-325.

- MaximeMussard and Ole JørgenNydal. 2013. Charging of a heat storage coupled with a low-cost small-scale solar parabolic trough for cooking purposes, Solar Energy, 144-154.

- More, A. and Wagh, M. 2017. Feasibility of Solar Steam Cooking for 500 Students Using Scheffler Dishes at Institute Canteen. International Review of Mechanical Engineering (IREME), 11 (10), 737-742.

- Mohanand B and Deepika Vasanthakumar. 2015. Analysis of the effectiveness of solar assisted steam cooking using parabolic trough collector. International Research Journal of Engineering and Technology (IRJET), 2(4),932-939.

- Mat McDermott. https://www.treehugger.com/renewable-energy/worlds-largest-solar-cooking-system-installed-in-india.html.

- Chaturvedi P, May. 2005. Renewable Energy in India Programmes and Case Studies. ISESCO Science and Technology Vision,1, 61-64

- (https://solarenergydemystified.wordpress.com/2010/03/08/solar-steam-cooking-system-at-tirumala/).

- ENVIS Center on Human Settlement's, Hosted by School of Planning and Architecture, Sponsored by Ministry of Environment, Forests& Climate Change, Government of India.

- http://ureda.uk.gov.in/pages/display/137-solar-steam-cooking.