Chemical and Microbiological Analysis of Organic Manure of Nisargruna Biogas Plant and its Applications as Carrier Materials for Biofertilizers

1

Department of Microbiology,

Rayat Shikshan Sanstha’s Karmveer Bhaurao Patil College,

Vashi, Navi Mumbai,

India

2

Nuclear Agriculture and Biotechnology Division,

Bhabha Atomic Research Center,

Mumbai,

India

Corresponding author Email: shubhada009@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.15.3.17

Theuse ofNisargruna biogas plant is an efficient approach to recycle the biodegradable wastematerials into valuable products like organic manure, methane carbon dioxide and water. In the current study, the manureobtained from five different Nisargruna biogas plants was analyzed for its characteristic properties. These properties included their chemical composition (carbon, hydrogen, nitrogen, sulphur and macro/micro-nutrients), water holding capacity and heavy metal concentration and coliform bacteria and fungi. The results indicated the presence of a high concentration of macro- and micronutrients, and the absence of coliforms. The samples with good nutrient contents were used as a carrier material forAzotobactersp., Rhizobiumsp. and phosphate solubilizing Bacillussp. On analysis, themanurewas found to be useful as carrier for selected cultures even after six months of production, hence confirming its stability and practical application.

Copy the following to cite this article:

Nayak S, Kale S. Chemical and Microbiological Analysis of Organic Manure of Nisargruna Biogas Plant and its Applications as Carrier Materials for Biofertilizers. Curr World Environ 2020;15(3). DOI:http://dx.doi.org/10.12944/CWE.15.3.17

Copy the following to cite this URL:

Nayak S, Kale S. Chemical and Microbiological Analysis of Organic Manure of Nisargruna Biogas Plant and its Applications as Carrier Materials for Biofertilizers. Curr World Environ 2020;15(3). Available From: https://bit.ly/2UXozkc

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 01-09-2020 |

|---|---|

| Accepted: | 18-11-2020 |

| Reviewed by: |

Roshan Kumar

Roshan Kumar

|

| Second Review by: |

Jasvarinder Chalotra

Jasvarinder Chalotra

|

| Final Approval by: | Dr Hiren B Soni |

Introduction

The primary component of the food chain, i.e., plants invest an enormous amount of solar energy to support all life forms on earth. Every living creature is dependent on plants for their survival, either directly or indirectly. The perfection of natural processes is evident from the biogeochemical life cycles that occur sustainably. In order to balance the exploitation of resources obtained from nature and maintain continuity in life, it is necessary that we recycle the elements derived from plants. Although incineration can achieve this purpose faster, it is not proper approach as it would delay the recycling considerably. The eco-friendly way in which this can be achieved is through the process of microbiological treatment of biodegradable wastes. If left untreated, these wastes can negatively affect the biological cycles occurring in nature and hence may eventually challenge sustainability on this planet. Hence, wastes should not be considered as futile, but a vital reserve of precious elements and handled intelligently. Moreover, appropriate treatment of organic wastes can provide manure to replenish vanishing topsoil layers in nature, and overcome the energy crisis due to the production of bioenergy.

The Nisargruna biogas technology developed at Bhabha Atomic Research Centre, Mumbai, India,represents a simple biphasic system thatconverts the biodegradable wastes into nature-friendly end-products. Nisargrunais a Sanskrit word and in simple terms, it means returning the loan of Nature. We are borrowing everything that is needed for our life requirements. It is our duty to return these resources to Nature in an appropriate manner for sustainability. The Nisargruna biogas plant works on the principle of zero garbage and zero effluent production system togenerate energy in the form of methane gas. Besides, these are economically viable as they are designed to handle bulk waste generated in large establishments in a decentralized manner.

The blending of aerobic and anaerobic phases, in the current study, proved successful in terms of reduction in retention time, high process stability with a better-quality (purer)methane yield and better manure quality.Manure is rich in nutrients, odourless, and free from all heavy metals and weeds. The manure formed can be used as bio fertilizer and soil conditioner in agriculture practices.

Many studies have suggested the fulfilment of plant growth requirements on the application of bio-slurry and organic manure from bio digesters1,2,3. These studies encourage the use of manure as organic fertilizer, as it is more eco-friendly compared to chemical fertilizers. The solid fraction, obtained from the digester, is rich in organic matter as well as organic nitrogen and phosphorus. The properties of the solid fraction, if added to soils, are comparable to compost with one major exception: it is relatively more abundant in lignocellulose. This is due to the inability of lignin to decompose completely during anaerobic digestion, and further indicates the soil building ability of the solid fraction of digestate to decompose in the soil as compared to compost. The nitrogen mineralization of organic products strongly depends on their ability to decompose i. e. C/N-ratio of the organic matter in the manure4. The effectiveness of organic manure in increasing crop yield has been reported by several researchers5,6.

Every aspect of Nisargruna biogas plant is attractive in terms of its application. For instance, the by-products like biogas and manure provide economic feasibility. The manure generated in the process can help in rejuvenating the depleting organic carbon contents in our top layers of agricultural soils. Thus, considering these advantages, the chemical and microbiological analysisof the organic manure was crucial and was carried out with a hopeful attempt to change the aesthetic look of our country throughNisargruna technology.

The present study was carried out to study the characteristic properties of organic manure samples and improvise on their suitability to be used as a carrier material for bio fertilizers.

Material and Methods

Manure samples used

The manure samples collected from fiveNisargruna biogasplantsat different locations in Mumbai viz.Deonar abattoir, Shatabdi hospital, Govandi, Training School Hostel, Anushaktinagar, Nursery (Bhabha Atomic Research Centre)and Navy Nagar(Colaba), were used in the present study.All the selected plants used biodegradable kitchen waste, except Deonar abattoir plant which was fed purely with abattoir waste.

Estimation of water holding capacity of manure

To estimate the water holding capacity (WHC) of the air-dried manure, a 50g sample was weighed on a Whatman filter paper no.1 and placed in a funnel. The manure was wholly saturated with distilled water and excess was allowed to drain by keeping the manure covered, overnight. It was then dried in an oven, at 105°C, until a constant weight was obtained. The WHC was calculated using the formula represented below7.

Where, “A” is the weight of water retained by manure, “B” is the weight of wet manure and filter paper, “C” is the weight of oven-dried manure and filter paper, “D” is the weight of water held by filter paper, “E” is the weight of oven-dried manure and filter paper, “F” is the weight of dry filter paper and “G” is the weight of oven-dried manure.

Estimation of phosphorus in manure by Koenig and Johnson method

Digestion of the manure

The Perchloric acid method of digestion was carried out to oxidize the organic matter of manure effectively. A 0.5g manure sample was taken in a conical flask to which 20ml of digestion mixture (concentrated nitric acid and perchloric acid in 5:1 proportion) was added. The mixture was then heated on a hot plate, and evaporated gently until dense white fumes of HClO4 just appeared. The digested solution was cooled, filtered and transferred to 50ml volumetric flask.

The volume was made up to 50ml with distilled water. The acid digested sample (0.5ml) was treated similarly as standards, and the developed colour was measured spectrophotometrically at 420nm7.

The concentration of phosphorus in the sample was determined by extrapolating the absorbance of the sample on the standard graph. The standard graph was prepared by Koenig and Johnson method. Various standard concentrations of phosphorus were prepared from aliquots of KH2PO4 stock (100ppm) and calculated using the formula represented below.

Estimation of potassium by flame photometer

The concentration of potassium in 5 different manure samples was estimated by using flame photometer [Model no. CL360, Elico, India]. The manufacturer’s recommendations were followed for operation and measurement. The potassium content was determined and calculated according to the standard protocol 7.

Estimation of heavy metals and micronutrients in manure

The estimation of heavy metals like- arsenic, cadmium, chromium, nickel, lead, and cobalt was essential in order to determine the safety with regards to the use of the manure obtained from Nisargruna biogas plant, as a fertilizer and soil conditioner. The heavy metals and micronutrients were measured by using flame atomic absorption spectrophotometer (Perkin-Elmer GBS-932plus). For this purpose, the manure was digested using the perchloric acid method described above. The manufacturer’s operating instructions were followed during the measurement. After stabilization of flame for a few minutes, a blank consisting of deionized water was aspirated, and the instrument reading was adjusted to zero. For standardization, three concentrations of each standard metal solution, to bracket the expected metal concentration of a sample, were selected. After rinsing the atomizer, the standard and test samples were aspirated and absorbance was recorded. The concentration of each metal was calculated by referring to the appropriate calibration curves.

Analysis of carbon, hydrogen, nitrogen, sulphur and total organic carbon content of manure

Manure samples (100µg) from five different Nisargruna biogas plants were analyzed for their carbon, hydrogen, nitrogen and sulphur content by automated CHNS analyzer (EURO EA 3000 Elemental analyzer, EuroVector). The total organic carbon content was measured by TOC analyzer [TOC-V CSH- Shimadzu TOC analyzer].

Estimation of total bacterial count and total fungal count of manure

Ten gram of organic manure sample was added to 90ml of sterile saline and mixed well. The supernatant was diluted further by serially diluting it up to 10-6dilutions. Dilutions were spread on sterile pre-dried plates of sterile nutrient agar and Rose Bengal potato dextrose agar for isolation of bacteria and fungi, respectively. The experiments were carried out in triplicates, and the plates were incubated at 27°C for 24-48h. After incubation, colonies were counted, and colony-forming units per ml (cfu/ml) were estimated8.

Detection of coliforms and pseudomonads in manure

The presence of coliforms and pseudomonads in manure was checked by spreading the various dilutions of manure on MacConkey’s agar plates and Cetrimide agar plates respectively. The plates were incubated at 37°C for 24h and observed for the presence of colonies8.

Determination of suitability of the manure as a carrier material for Azotobactersp., Rhizobiumsp. and phosphate solubilizing Bacillus sp.

The manure sample (250g) having 30% moisture was autoclaved was mixed with 1% inoculum consisting of fresh suspensions of Azotobacter sp., Rhizobium sp. and Bacillus sp.(a phosphate solubilizer). The mixture was then stored in plastic bags and kept at room temperature. The viability of all the above cultures was checked every week for six months, by spreading the suspension of manure on Ashby’s mannitol agar, Congo red yeast extract mannitol agar and Pikovasky’s agar, respectively. The plates were incubated at room temperature for 48-72h and observed for the presence of growth8.

Statistical analysis

All experiments were carried out in triplicates, and the data was analyzed by ANOVA. The results were considered to be significant at p ≤ 0.05.

Results and Discussion

The characteristic properties of the second important product of Nisargruna biogas technology, i.e., the manure, including the WHC, CHNS composition, macro- and micronutrient content and heavy metal concentrationsfrom five different plants were analyzed in our study. This was done to evaluate the quality and suitability of the manure to be applied as a fertilizer and soil conditioner in agriculture.

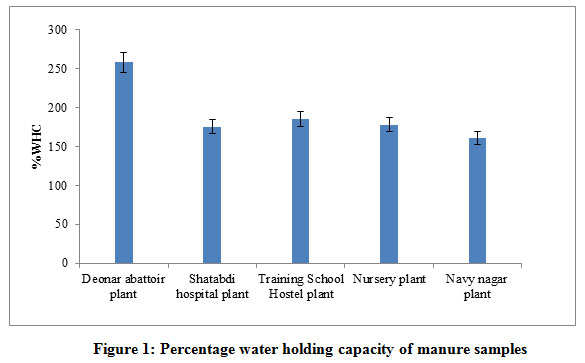

Estimation of WHC of manure

Fig.1 represents the WHC content of five manure samples collected from different Nisargrunabiogas plantsin our study.They were found to be in the range of approximately 160% to 185% except for the manure sample from Deonar abattoir plant, Govandi that runs only on abattoir waste. It showed a comparatively high WHC of ~250%. This may be due to the presence of intestinal wastes of slaughtered animals in Deonar abattoir sample, which contains large quantities of undigested fibrous material. These materials are not completely degraded during the process and hence appear in the manure,probably increasing itsWHC.

The nutrient-rich manure is a valuable by-product obtained from Nisargrunabiogas plant apart from methane. The manure is especially crucial since it has very high WHC and can be used in agriculture to replenish the deteriorating topsoil layers. Haque9 and Kumar et al. .10 reported that the biogas slurry, used as a fertilizer,generally consists of 93% water. Abebe11 reported 40.21% moisture content in composted organic fertilizer. They also reported that the WHC increases with the addition of organic fertilizers; however, this increase varies with the soil texture. Further, their resultsindicated that the addition of cow dung increased the WHC by two-fold as compared to the composted organic fertilizer. This is because the water retained by the cow dung is utilized by the plants enhancing their growth12.

The WHC also decides the extent of soil microbial activity and formation of soil aggregates. In our study, the WHC of the digestate was positively influenced by the digestate concentration. Alburquerque et al13 found that the WHC highly depends on carbon content, and the use of organic fertilizers is essential for maintaining the sustainability of the soil. In another study, 40% WHC was reported in the digestate5. As compared to the cited reports, the manure samples used in the current study showed very good WHC.

|

Figure 1: Percentage water holding capacity of manure samples Click here to view figure |

Estimation of phosphorus in manure by Koenig and Johnson method

The concentration of phosphorus estimated in five different samples used in our study is represented in Fig. 2. The highest phosphorus content (20-21ppm) was found in the manure collected from a plant located at Shatabdi hospital, Govandi, whereas minimum phosphorus content (3-4 ppm) was observed in manure from Deonar abattoir plant.

Phosphorus content of manure is equally important as Pcontents is an important factor that decides the efficiency of manure as a fertilizer. Haque9 reported the presence of 1.55% phosphorus, on an average, in the digestate of the biogas plant. Ghosh14 also reported 1 to 1.5% of phosphorus content in manures samples, in their study. The presence of 3.6 kg/ton of phosphorous content in a combination of dry and wet fertilizer prepared in the previous study10.

|

Figure 2: Concentration of phosphorus in various manure samples Click here to view figure |

|

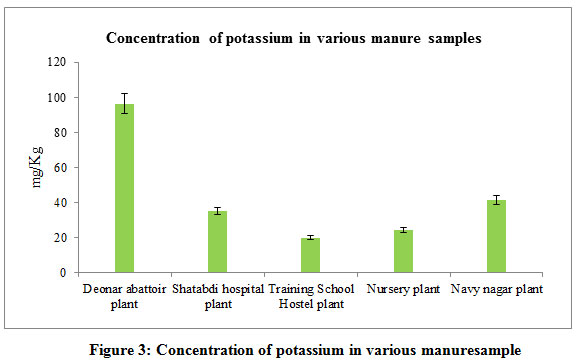

Figure 3: Concentration of potassium in various manuresample Click here to view figure |

Estimation of potassium by flame photometer

Potassium is the third most crucial mineral element required for plant growth. In the current study, the Deonar abattoir manure sample showed the highest concentration of potassium, i.e. 95-96ppm. All other manure samples contained ~20-40ppmpotassium (Fig. 3).

Our observations indicate that the composition of manure depends on the feed or raw material used in the Nisargruna biogas plant. All plants, except the one at Deonar abattoir, were fed with kitchen based organic wastesand lower amounts of garden waste. In contrast, the Deonar abattoir plant was fed with abattoir waste and thus its manure showed very high WHC and potassium concentration, and low phosphorous concentration.In another study, cow dung and compost showed 0.5% and 1.4% of potassium concentration1. Similarly, the bioslurry digestate showed 0.80-1.20% of potassium content 9.A combination of dry digestate and wet bioslurry, as a fertilizer, showed 0.9 to 1.6 Kg/cubic meter potassium content10.

Estimation of heavy metals in manure

The presence of heavy metals in manure is not desirable as plants easily utilize the nutrients along with these metals. Thus they become a part of the food chain and cause many health adversities in humans and animals. Biomagnification further alleviates the severity of the problem. On the other hand presence of micronutrients like manganese, iron, copper and zinc in manure is beneficial as they support the plant growth. Thus, the presence of these micronutrients increases the value of the manure as a fertilizer.

In the current study, heavy metal analysis of manure samples was carried out in order to find its suitability as a safer fertilizer. The results of heavy metal concentrations in different samples are indicated in Table 1.

Table 1:Heavy metals in various manure samples

|

Sample |

Cadmium (mg/Kg) |

Chromium (mg/Kg) |

Nickel (mg/Kg) |

Lead (mg/Kg) |

Cobalt (mg/Kg) |

|

Deonar abattoir plant |

4.4 |

1.3 |

91.8 |

101.6 |

68.2 |

|

Shatabdi hospital plant |

0.5 |

1.8 |

09.2 |

21.5 |

04.6 |

|

Training school hostel plant |

3.9 |

1.0 |

07.4 |

12.0 |

06.6 |

|

Nursery plant |

2.5 |

7.0 |

63.9 |

62.5 |

23.0 |

|

Navi Nagar plant |

4.5 |

3.8 |

43.0 |

56.6 |

35.1 |

The manure produced in biogas plants,fed with kitchen wastes,show the presence of heavy metals within the standard range provided by the Gazette of India. In contrast, the manure produced in the biogas plant fed with abattoir waste contains slightly higher concentrations of nickel and lead. A similar study reported the presence of cadmium, total chromium, mercury, nickel and lead in the concentrations of 0.44, 14.35, 0.07, 16.18 and 8.38 mg/Kg respectively, in the digestate obtained from Austrian biogas plant15. In another study, the concentrations of total heavy metals such as cadmium,total chromium, hexavalent chromium, copper, mercury and leadwere recorded as 0.4, 16, <0.2, 59. 0.2 and 6mg/Kg, respectively6. As compared to these reports, the heavy metal concentrations in the selected manure samples, in our study, were found to be lower. Hence, they can be safely used as a soil conditioner, and manure for increasing crop yield.

Estimation of micronutrients, CHNS content and TOC in manure

Micronutrient analysis of manure samples was done to estimate the concentration of elements like manganese, iron, copper and zinc. These micronutrients, if found in excess,may impair the plant growth15. The carbon, nitrogen and sulphur content of manure decide its value as a fertilizer.

The concentration of Mn, Fe, Cu and Zn found in the selected manure samples are represented in Table 2. The observed results for CHNS content and TOC of the selected manure samples are represented in Table 3. The approximately same concentration of HNS was observed in all samples used in our study. The manure from Thane plant showed the highest carbon content of 30.8% whereas the highest TOC content of 7.686% was found in the manure sample from the nursery plant. In a similar study, an average iron content of 5476.67mg/kg and average manganese content of 338.58mg/Kg in digestate sample used as fertilizer15.

Table 2: Micronutrients in various manure samples

|

Sample

|

Manganese (mg/ml) |

Iron (mg/ml) |

Copper (mg/ml) |

Zinc (mg/ml) |

|

Deonar abattoir plant |

1.523 |

0.960 |

2.605 |

0.544 |

|

Shatabdi hospital plant |

0.246 |

1.204 |

0.705 |

0.417 |

|

Training school hostel plant |

0.245 |

0.640 |

0.362 |

0.33 |

|

Nursery plant |

0.746 |

3.975 |

1.198 |

0.589 |

|

Navi Nagar plant |

1.733 |

0.890 |

1.072 |

0.5 |

Table 3: CHNS and TOC of the selected manure samples

|

Sample |

Carbon% |

Hydrogen% |

Nitrogen% |

Sulphur% |

TOC% |

|

Deonar plant |

24.0 |

3.5 |

1.9 |

<0.2 |

3.361 |

|

Shatabdi plant |

22.2 |

3.7 |

2.9 |

<0.2 |

6.229 |

|

TSH plant |

20.9 |

3.3 |

2.9 |

<0.2 |

8.261 |

|

Nursery plant |

17.4 |

2.9 |

1.9 |

<0.2 |

7.686 |

|

Navi Nagar plant |

30.8 |

3.7 |

2.9 |

<0.2 |

5.811 |

Estimation of total bacterial count and total fungal count of manure

For a manure to be safely used, it is most important to determine the number of microorganisms present in it. In the current study, the total bacterial count and total fungal count of manure samples were estimated and found to be in the range of 107-108 cfu/ml and 104 -106 cfu/ml respectively.

Detection of coliforms and pseudomonads in manure

In order to use the manure samples as fertilizers, the digestate should be free of pathogens, toxins or infectious agents that pose a risk to the health of humans, domestic animals or crops15.In this study, the manure samples showed less prevalence of pseudomonads (90-100cfu/ml) and the absence of coliforms.The observations, especially the absence of coliforms is very important from the public health point of view. This is because there are chances of contamination and spread of diseases during handling of manures, and contact with plants and animals. The results obtained in the present study are in agreement that showed absence ofE.coli, Salmonella, Listeria and Campylobacter in the digestate15. In another study, the presence of E. coli, Salmonella and Staphylococcus species in the initial stages of manure production was reported16. After 30 days, the number of these bacteria was reduced and found to be absent when analyzedafter 60 days. In general, the microbial load, after treatment of animal manure via anaerobic digestion in a biogas plant, is observed to reduce considerably, and this reduction depends on the duration and temperature of digestion.

Determination of suitability of the manure as a carrier material for Azotobactersp., Rhizobiumsp. and phosphate solubilizing Bacillus sp.

In order to augment the value of manure, it is a common practice to append it with symbiotic and non-symbiotic nitrogen fixers and phosphate solubilizers. Ourstudy showed good growth of all the selected bacterial strains used as biofertilizers.It was observed that the manure samples could support the above cultures effectively for more than six months. To the best of our knowledge, this is the first report, among published data, of using manure as a carrier for biofertilizers.

Conclusion

The selected manure samples were found to be rich in macronutrients and contained the required concentration of micronutrients sufficient to support the plant growth. The manure samples were devoid of any pathogens; hence it can be used without any health risks. All samples supported the growth of bacteria used as biofertilizers for more than six months. Hence such valuable manure – a Browngold can be effectively used not only for increasing crop yield but also as a useful eco-friendly carrier material for biofertilizers. In the current environmental and climate crisis and ever-increasing fuel costs leading to higher agricultural inputs, it is necessary to explore the full potential of the biogas technology and lead a sustainable approach to meet our energy requirements.

Funding Source

The author(s) received no financial support for the research, authorship, and/or publication of this article.

Conflict of Interest

The authors declare no conflict of interest.

Acknowledgment

The authors sincerely thank Dr. Madhuri Sahasrabuddhe, Dr. Darshana Salskar and Dr.SayajiMehetre for their valuable cooperation and inputs.

References

- Devarenjan J, Joselin-Herbert G. M, Amutha D. Utilization of bioslurry from biogas plant as fertilizer.Int J Recent Technol Eng. 2019;8(4):12210-12213.

CrossRef - Locoli G, Zabaloy M.C, Pasdevicelli G, Gomez M.A.Use of biogas digestates obtained by anaerobic digestion and co-digestion as fertilizers: Characterization, soil biological activity and growth dynamic of Lactuca sativa L. Sci Total Environ. 2019;647:11-19.

CrossRef - Wentzel S, Joergensen R.G. Effects of biogas and raw slurries on grass growth and soil microbial indices. J Plant Nutr Soil Sci. 2016;179(2):215-222.

CrossRef - Bonten L.T.C, Zwart K.B, Rietra R.P.J.J, Postma R, Hass M.J.G. Is bio-slurry from household digesters a better fertilizer than manure? A literature review. Wageningen UR (University & Research centre), Alterra report 2519, 2014.

- Nabel M, Schrey S.D, Poorter H, Koller R, Jablonowski N.D. Effects of digestate fertilization on Sidahermaphrodita: Boosting biomass yields on marginal soils by increasing soil fertility. Biomass Bioenerg. 2017;107:207-213.

CrossRef - Valentinuzzi F, Cavani L, Porfido C, Terzano R, Pii Y, Cesco S, Marzadori C, Mimmo T. The fertilising potential of manure-based biogas fermentation residues:pelleted vs. liquid digestate.Heliyon2020;6:e03325.

- SadasivamS, Manickam A. Biochemical Methods. Third Edition. Hyderabad. New Age International Publishers. August 2008. ISBN? PAGES?

- Dubey R, Maheshwari D.K. Practical Microbiology. Revised Edition. S Chand Publications. New Delhi 2014. ISBN? PAGES?

- Haque A. Bio slurry ultimate choice of biofertilizer.Sci Rep. 2013;2(4):1-8.

- Kumar S, Malav L. C, Malav M.K, Khan S. Biogas slurry: source of nutrients for eco-friendly agriculture. Int J Ext Res. 2015;2:42-46.

- Abebe M. Characterization of sludge from a biogas reactor for the application bio-fertilizer. Int J Sci Eng Sci. 2017;1(3):12-16.

- Vengadaramana A, Jashothan P.T.J. Effect of organic fertilizers on the water holding capacity of soil in different terrains of Jaffna peninsula in Sri Lanka.J Nat Prod Plant Resour.2012;2(4):500-503.

- Alburquerque J. A, Fuente C D, Campoy M, Carrasco L, Nájera I, Baixauli C, Caravaca F, Roldan A, Cegarra J, Bernal M. P. Agricultural use of digestate for horticultural crop production and improvement of soil properties. Eur J Agron. 2012;43:119-128.

CrossRef - Gosh K. Biogas Manure: An amazing Organic Fertilizer. www.ektitli.org/2012/07/25/biogas-manure-an-amazing-organic-fertilizer/. 25/7/2012 Published date. 10/8/2020 Updated date. 20/7/2020 Accessed date.

- Sturmer B, Pfundtner E, Kirchmeyr F, Uschnig S. Legal requirements for digestate as fertilizer in Austria and the European Union compared to actual technical parameters. J Environ Manag. 2020;253:109756.

CrossRef - Islam M, Biswas P, Momen A, Haque Z, Saha C, Alam M, Rahman M, Saha S. Microbial load in bio-slurry from different biogas plants in Bangladesh. J Advanced Vet Animal Res. 2019;6(3):376-383.

CrossRef