Challenges of Distillery Effluent Treatment and its Bioremediation Using Microorganism: A Review.

1

Department of Microbiology,

Faculty of Science, Dr.Ram Manohar Lohia Avadh University,

Ayodhya,

Uttar Pradesh

India

Corresponding author Email: ranjan.singh13@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.18.2.03

Copy the following to cite this article:

Patel A, Gaur R, Verma T, Singh R. Challenges of Distillery Effluent Treatment and its Bioremediation Using Microorganism: A Review. Curr World Environ 2023;18(2). DOI:http://dx.doi.org/10.12944/CWE.18.2.03

Copy the following to cite this URL:

Patel A, Gaur R, Verma T, Singh R. Challenges of Distillery Effluent Treatment and its Bioremediation Using Microorganism: A Review. Curr World Environ 2023;18(2).

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-01-15 |

|---|---|

| Accepted: | 2023-06-08 |

| Reviewed by: |

Atun Roy Choudhury

Atun Roy Choudhury

|

| Second Review by: |

Angeles Martínez Toledo

Angeles Martínez Toledo

|

| Final Approval by: | Dr. Mohammad Oves |

Introduction

Bioremediation is the process of biologically degrading potentially harmful substances in the environment. Bioremediation is the naturally occurring phenomenon of biodegradation, which breaks down pollutants and, in some cases, completely oxidizes the chemical. Due to their metabolic variety, which includes the ability to metabolite these pollutants1, microorganisms play a crucial role in the bioremediation and biodegradation processes. Bioremediation2 refers to the transformation of toxic substances into less hazardous forms throughout the use of biological processes. The amount of harmful compounds that bioremediation can cure is constrained, yet when applied, it is economical and ecologically benign. The majority of our aquatic environment is badly contaminated as a result of our nation's fast population development, rapid industrialization, modernization, rising living standards, and more human activity.Numerous rivers around the world are impacted by industrial effluents4. When utilised for irrigation, wastewater containing elements ranging from basic nutrition to highly poisonous substances generated both good and detrimental effects on numerous crops, including vegetables5.

Approximately 2300 million liters6 of ethanol were produced annually in India during 2006-2007. In 2009, 319 distilleries generated 3,25109 litres of alcohol and 40,401010 litres of wastewash7. In distilleries, the primary product, pure ethyl alcohol, is refined. Each year, around 2,7 billion litres of alcohol were manufactured. Undesirable rinse, a liquid waste byproduct, has been produced as a result of this technique. This waste's BOD has grown because it contains organic materials notably lignin, melanoidins, reducing sugars, waxes, proteins, and polysaccharides8. Traditional batch and continuous distilleries create between 10 and 15 kL of spent wash every 1 kL of alcohol. Listed alcohol production industries given the presence of a water-soluble, extremely resistant to microbial attack pigment called melanoidin and the inability of current biological techniques to treat this pigment, effluent from distilleries and fermentation businesses is the leading cause of soil and aquatic pollution.Melanoidin is produced from the distillation and fermentation industries. Therefore, this effluent must be pre-treated prior to release into the environment in a safe manner. Chemical procedures have been used to degrade and decolorize this effluent; however, these procedures are not commercially fruitful on industrial scale due to expensive nature. Microorganisms have successfully degraded melanoidin; hence, bioremediation approaches can be utilised.

Characteristics of the aerobically treated distillery spent wash

Higher pH, BOD, and COD concentrations are found in the raw distillery wasted wash. Reports state that distillery waste wash is a very complicated waste with elevated Color COD, TDS, and BOD that harms the environment and is difficult to successfully manage. It also contains significant quantities of melanoidin.Conventional distillery wasted wash treatment necessitates high operation costs and chemical agent consumption, retention of colour after treatment, high sludge output, toxic byproducts, and increased energy demands.

Melanoidin

Melanoidin is a water-soluble, refractory molecule that adds colour to distillery and fermentation industry wastewater. According to reports, the brown pigment melanoidin is created by nonenzymatic amino carbonyl reactions, also known as the Maillard reaction. According to reports, the toxicity of melanoidin to microorganisms11 was caused by the compound's high antioxidant content. Melanoidin is also naturally prevalent in meals and beverages12. However, Melanoidin lacks a distinct structure, and its elemental composition is still not entirely understood13. Melanoidin, according to reports, blocks sunlight from accessing water bodies, hence diminishing photosynthetic activity and dissolved oxygen. According to reports, it is detrimental to aquatic organisms. Research14 demonstrated that ketose sugars were significantly more carcinogenic than their aldose isomers and produced active oxygen radicals that led to DNA strand breakage and mutagenesis. It was calculated15the toxic effects of excessive distillery effluent spent wash on the freshwater fish Cyprinuscarpiovar Communis. Owing to the existence of water-soluble refractory pigment compounds known as melanoidins, which are exceptionally resistant to microbial attack, fermentation businesses, distilleries enterprises are reported to contribute vastly in soil and water pollution.

Relying on the reactant composition, reaction circumstances, pH, heating period water, temperature, and other factors16, melanoidin can have various chemical compositions. Maillard reaction products (MRPs) operate as reducing agents17, metal chelating agents18, and radical scavengers19, according to in vitro studies. The melanoidin is formed through generalized Maillard reaction process. The MRPs in text boxes of various colours correspond to three-step reaction products. The yellow frames indicate early-stage items, the green frames represent middle stage products, and the blue frames represent final stage products. Importantly, the peptide cannot undergo the standard Strecker breakdown, which results in a difficulty to decarboxylate, since there are no free carboxyl functional groups on the -carbon, in contrast to free amino groups.Adaptation permitted20 American Chemical Society (1953).

Nature of Melanoidins

Distillery Melanoidins may be found in previously worn garments. Melanoidins are condensates of sugars and amino acids that are formed by reflected aminocarbonyls that are not enzymatic in nature. The carbonyl group and amino group are connected in the molecules that constitute the chemical substances. Melanoidin production may be influenced by a number of variables, including the chromophore and its quantity, a range of catalysts and buffers, temperature, timescale, meatal ions, water activity, availability of oxygen, and pH21.Melanoidins, because of their intricate structure and xenobiotic origin, often resist being broken down by biological processes.Melanoidins have been given the empirical formula C17-18H26-27O10N. In rivers, lakes, and lagoons, the discharge of wastewater containing melanoidins lowers solar light penetration, therefore reducing photosynthetic reaction and DO concentration.

Two types of wastewater are produced by distilleries: nonprocess wastewater and process wastewater. Byproducts consist of ethyl acetate, acetic acid, and acetaldehyde, in addition to the products ethyl acetate, acetic acid, and acetaldehyde23. The water is so polluted that it is worthless due to the large quantities of inorganic and organic pollutants that are prevalent in the extremely acidic and unprocessed distillery effluent wash24. The discharge of distillery effluent into aquatic habitats leads to a reduction in the amount of dissolved oxygen and causes changes in the respiratory metabolism of a variety of organisms25-27. In addition, India's Ministry of Environment and Forests (MoEF) has determined that distilleries are the leading industry in the "Red Category"28.

Used laundry contains melanoidins as a result of the distillery industry's release of wastewater into water systems, which has decreased the availability of water and lowered the water quality. Melanoidins are organic compounds produced via non-enzymatic reflected aminocarbonyls and are occurring naturally condensates of amino acids and sugars. Dye is one of the principal contaminants found in textile, plastic, distillery, food, and cosmetic industry effluents29. Industrial raw dyes have a more dangerous, carcinogenic, mutagenic, and genotoxicity character30. In addition to causing aquatic pollution, the presence of melanoidin in the effluent from fermentation and distillation industries contributes to the pollution of waterways. According to reports, this colouring agent is very resistant to both microbial and conventional biological processes10.

Anaerobically, the COD of sewage is about 90,000 mg/L31 and it is dark brown in colour. resistance to effluent bioremediation32. Typically, anaerobically treated distillery effluent33 has a greater proportion of organic contaminants. Environmental deterioration occurs when effluent containing dangerous chemicals like volatile organic compounds, toxic salts, and heavy metal ions is deposited into the soil.Depending on the kind of wastewater, irrigation with industrial wastewater has been observed to alter seed germination in a variety of crops34-35.

The presence of COD (ranging between 30 and 35000 parts per million), BOD (ranging between 8 and 10000 parts per million), total solids (ranging between 60 and 65000 parts per million), and organic substances.Even when anaerobic treatment of wastewater reveals that standard treatment technologies are useless, they continue to be utilised.It turned out to be well beyond the safe disposal limit. Organic and inorganic components in ADSW must be decomposed. This study used a Pseudomonas sp. culture that was abundant since it was more efficient and would help in the future. For soil bacteria contaminated with ADSW and up to 18.15 % for soil bacteria polluted with DEE, the microbial system group reduced the organic contaminant (COD) of ADSW by approximately to 26.05 %.In addition to free bacterial treatment, standard immobilisation of microorganisms in sodium alginate was used to assess a decline in contamination load in ADSW.This microbial system can also be used in conjunction with aerobic methods to further reduce COD showed in Table1.

Physical-chemical procedures may be able to extract melanoidin, but they require a large number of reagents and produce a substantial amount of sludge36. As a result, microbial methods provide a financially advantageous and ecologically responsible alternative to chemical breakdown procedures37.

Table 1. Physical and chemical properties of spent wash from a distillery.

Parameters | Value (mg/l) |

Odour | Like Molasses |

pH | 3.2 |

Color | Dark Brown |

Temperature | 30.7°C |

COD | 1440 |

Dissolved O2 | 10.14 |

Total Solids | 626 |

Total Dissolved Solids | 360 |

BOD | 58.33 |

Total Suspended Solids | 266 |

Electrical Conductivity | 6.6114 mmhos |

Several Secondary treatment methods were utilised to decolorize used distillery laundry. Activated carbon38, charcoal39, pyrchar40, and inorganic flocculants41, ammonium sulfate39, oxidation process42, and moist air oxidation43 are examples.

Recently, melanoidin-containing wastewater has been treated using chemical precipitation and carbon adsorption. Although these methods are successful, they have a number of drawbacks, including high operation costs and chemical agent consumption, fluctuating colour removal, and significant sludge/solid waste production44. Therefore, an alternate treatment for the reduction of industrial wastes and effluents could be degradation and decolorization mediated by microorganisms. For the ecologically friendly and cost-effective biodegradation of complex, hazardous, and resistant compounds in distillery waste wash, it is preferred to utilise microorganisms such bacteria, fungus, yeast, and algae45,11,46. Coriolus versicolor Ps4a47, Aspergillus fumigates G-2-648, Rhizoctonia sp. D-9049, Lactobacillus hilgardii50, and Bacillus sp.51 were used to treat molasses wasted wash containing a greater content of melanoidin. According to a study52, the toxicity and increased concentration of distillery effluent might induce abnormalities in seed germination, seedling growth, and growth hormone inhibition. Thus, factors like as temperature, aeration, nutrients, and pH have a role in the dye removal and biological degradation of untreated wastewater 53,28. In addition,54 utilised nano filtration (NF) and reverse osmosis (RO). According to numerous investigations, the distillery wasted wash is decolored by Lactobacillus hilgardii50, Bacillus sp.51, Pseudomonas putida55, Bacillus thuringiensis53, and Pseudomonas aeruginosa45. Since longer time, fungi, bacteria, yeast, and algae have decolored the complex, poisonous, and recalcitrant chemicals included in distillery spent wash56, 44.

Methods for Decolourization

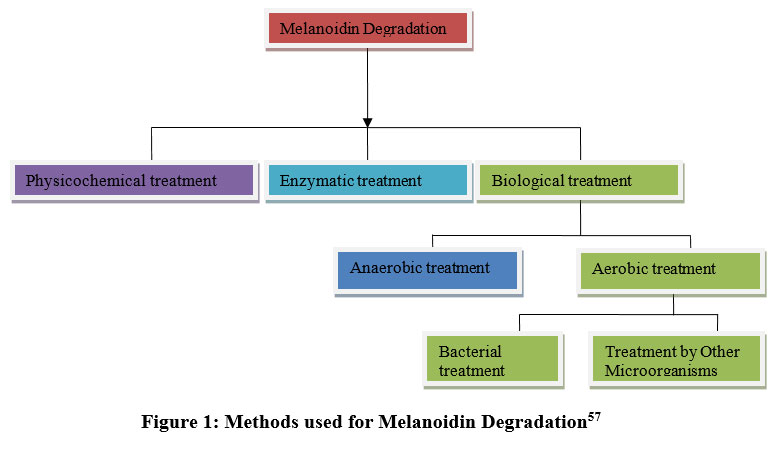

Researchers have proposed various physical, chemical, biological, and enzymatic approaches for decolorizing used laundry after anaerobic treatment. Adsorbents like activated carbon and coagulants including starch, bentonite, activated silica, and polyelectrolytes were used in physical therapy. Oxidants of various types, such as fenton's reagent, ozone, and mono hydrogen peroxide, were also used. Except for solitary hydrogen peroxide and Fenton's reagent45, all colour removal procedures yielded an efficacy of between 70 and 90%. Numerous procedures for decolorization have been investigated, however they all require significant quantities of chemicals and generate large quantities of sludge. In order to remove pigments, biological treatment can either thicken the sludge or partially or totally degrade the pigment molecules. The anaerobic treatment of wasted wash results in a significant concentration of organic and coloured contaminants. The purpose of waste treatment is to eliminate dangerous elements from wastewater prior to its release into the environment in a safe manner. Diverse methods, such as physical and chemical treatment and biological treatment (Figure 1), have been used to lower the pollution load from distillery effluent.

| Figure 1: Methods used for Melanoidin Degradation57

|

Biological treatment methods

Bacterial treatment

Decolorization and deterioration of spent wash from distilleries have been a significant environmental concern58-60. Melanoidin compounds are resistant to several wastewater treatment plant cycles, allowing them to escape and into the environment. There is few research on microbes as pollutants reducers and none on the degradation of melanoidin, according to a survey of the relevant literature. In the current study, four strains from four different genera were examined for their capacity to disintegrate and remove impurities waste wash that had been handled aerobically but without nutrient supplementation.The organisms' ability to degrade colour ranging from 10 to 80%, and the quantity of their degrading effectiveness is greater in consortiums than in single strains. Therefore, the study demonstrates that indigenous microorganisms have significant potential and may be employed as bioremediation agents for distillery wastewater. At the beginning, three separate bacterial strains were tested in suspension cultures and collaborated in biosorption experiments, however their dye degradation capacities differed.

In recent decades, culture of pure bacteria for microbiological treatment has been documented frequently. Bacillus species have potency to decolorize approximately 35.5 % of molasses wastewater in just 20 days at 55 °C 51 under aerobic atmosphere. In the review, in Table 261 we provide a comprehensive list of bacteria explored by asunder researchers for decolourization of distillery effluent. The acclimation of bacterial strains isolated from effluent to increase in concentration of distillery waste. In 4-5 days no aeration, these strain was capable of lowering COD by 80%. The vital outputs of the treatment using bacteria were CO2, volatile organic compounds, and biomass. Pseudomonas fluorescens isolated by Dahiya et al. from liquid reactor, found all bacterial strains can decolorize melanoidin effluent by approximately 76% and 90 % in non-sterile as well as sterile environments respectively60.Melanoidin permanence fluctuates with pH and temperature., which may contribute to differences in colour change. At a higher temperature, melanoidin-pigments used for sterilisation breakdown into low molecular weight compounds50. Following anaerobic digestion, the pH of distillery waste wash rises from 4.5 to 8.5, and the resultant effluent is referred to as post methanated distillery effluent (PMDE).Using distinct aerobic and anaerobic strains, several investigations have looked at the disintegration of PMDE and colour changes, including lower absorbance at 475 nm, bacterial growth at 620 nm, increased biomass, and diminished colour intensity.It's been done45,62,28,44,63. Ohmomoet al.50 utilised calcium alginate-immobilized Lactobacillus hilgardi cells to achieve a 40% decolorization of melanoidin solution. For decolorization, a tiny amount of oxygen is required continually with minimal aeration. Using immobilised entire cells, a number of researchers performed melanoidin decolorization. An attempt was made to decolorize molasses wastewater by immobilising Pseudomonas fluorescence cells on a porous cellular carrier; 76% decolorization was achieved in 24 hours at 30°C. In a study, three bacterial strains were identified as Bacillus cereus, Bacillus megaterium, and B. fragairae64 from activated sludge of stillage. It was discovered that these eliminated colour and COD from 38-58 and 55-58 stillages. 68 percent coverage. Sirianuntapiboon et al.24 identified an acetogenic strain shown in table 2.

Table 2: Utilized bacteria in the decolorization of distillery effluent

Name | Description | Colour removal (%) | References |

Xanthomonas fragariae | All three bacteria needed the carbon and nitrogen sources glucose and NH4Cl. Immobilized cells were less successful in decolorizing than free cells. | 76 | [64] |

Bacillus smithii | When peptone was available, decolorization took place in 20 days at 55 °C in anaerobic circumstances with yeast extract serving as supplemental nourishment. Strain couldn't rely only on MWW as a supply of carbon. | 35.5 | [51] |

Lactobacillus hilgardii | 40% of the melanoidin solution was aerobically discoloured in four days by immobilised heterofermentative lactic acid bacteria. | 40 | [50] |

Acetobacter acetii | For the organism to quench municipal solid waste, sugar was required, namely glucose and fructose. | 76.4 | [44] |

Pseudomonas Fluorescens | Decolorization was accomplished using cellulose carriers covered with collagen. The effectiveness of decolorization was reduced when coloured cells were reused. | 94 | [60] |

Bacillus thuringiensis | As an additional carbon source, 1% glucose had to be added. | 22 | [28] |

Pseudomonas aeruginosa | The three bacteria formed a consortium that discoloured the composted manure wash in the inclusion of glucose and base salt. | 67 | [45] |

Fungal Treatment

Several Basidiomycetes and Ascomycetes-type fungi have been employed recently to decolorize both natural and manufactured melanoidin and lessen colour in distillery wastewaters. By consuming organic material, the fungus may screen wastewater and reduce its COD and BOD while simultaneously producing beneficial products like fungal biomass for protein-rich animal feed or a particular fungal metabolite.Compared to bacteria, filamentous fungus are less sensitive to changes in temperature, pH, nutrients, and oxygen, and their biomass contains less nucleic acid65. Aspergillus is one of the most-studied fungi capable of decomposing and decolorizing stillage. Aspergillus fumigatus, Aspergillus niveus, Aspergillus nigerAspergillus fumigatus G-2-6, and Aspergillus fumigatusUb260 resulted in an average decolorization of 69-75% and a COD removal of 70-90% 48,21,66. In Table 3, we evaluated the ability of several fungi to decolorize melanoidins from municipal solid waste. Coriolus sp. no. Twenty strains of Basidiomycetes were the first to remove melanoidins from household garbage in the year67. When molasses pigment was used as the carbon source, this percentage lacked dye removal activity; however, when glucose/sorbose was added, the activity was seen. Ohmomo et al.50 utilised Coriolus versicolour Ps4a for MSW decolorization in 1985 and achieved a dye degradation rate of 80% in the dark under ideal circumstances. Using autoclaved hyphae of Aspergillus oryzae Y-2-32, Omomo et al.50 adsorbed fractions containing low melanoidins, with the degree of adsorption dependent on the type of sugars employed for cultivation. Treatment of distillate wastewashing by ascomycetes such as Penicillium sps. was described by Jimnez et al.P. decumbens and P. lignatum, for instance, reduced colour and COD by approximately 50% and removed 70% of phenol. According to Sirianuntapiboon et al., Rhizoctonia sp. D-90 reduced the colour of synthetic and molasses melanoidin media by 84% and 87.5%, respectively showed in table 3.

Table 3: Fungi used to remove colour from distillery effluent

Name | Description | Colour removal (%) | References |

Corilushirsutus | In a solution containing glucose and peptone, the fungus discoloured melanoidin that was both synthesised and wastewater-derived. | 80 | [68] |

Pleurotusflorida Eger EM1303 | Distillery effluent that had been hydroponically treated was cleaned up by fungi. | 86.3 | [69] |

Flavodon flavus | These aquatic basidiomycetes discolour distillery toxic waste when there is 5% glucose present. | 80 | [70,71] |

Aspergillus niveus | The fungus may use sugar bagasse as a carbon source, and decolorization requires extra nutrients. | 56 | [72] |

Penicillium sp. | P. decumbens produced the most decolorization, which reduced the wastewater's phenol concentration by 70%, on the fourth day of incubation after all fungus started generating it on the first day. | 30 | [66] |

Mycelia sterilia | The metabolic process that causes the organism to become discoloured requires glucose. | 93 | [32] |

Aspergillus - UB2 | The proper amounts of diluted wastewater supplementation were used to accomplish this. | 75 | [73] |

Mixed consortium treatment

Several attempts have been made over the past two decades to examine the potential application of cell immobilisation in aerobic wastewater treatment technologies74-75. Previous tests were restricted to immobilised pure cultures on solid supports.Crosslinking occurs when portions of polymer chains adsorb to distinct particles, hence aiding in the aggregation of the particles. Given the cost of chemicals and sludge, as well as the degradation of dangerous compounds76,77, coagulation looks to be an expensive process. Later, immobilization consortiums of two or more selected strains were utilized78-79, whereas activated sludge was recently immobilised on several carriers and employed for wastewater treatment80. Adikane et al. assessed the decolorization of molasses wash effluent using soil as the inoculum in the lack of any additional carbon or nitrogen sources62.69% of the sample was discoloured over seven days of incubation with 10% (w/v) soil and 12.5% (v/v) solid waste from the municipality showed in table 4.

Table 4: Literature review for Bacterial and Fungal Decolourization.

Culture isolate or Consortium | Initial condition | Efficiency | Type of colour removal methods | Optimized condition | References |

Proteus mirabilis, Bacillus sp., Raoultellaplanticola and Enterobacter sakazakii | MM= 1000 ppm, Temp. = 35ºC, 180 rpm, Time= 240 h | 75% | Biodegradation (Confirmed by using live and autoclaved cells | Glucose, peptone, Temp. = 30-35ºC, pH = 7.0, Inoculum size = 4:3:2:1, Shaking speed= 100180 | [81] |

Alcaligenes faecalis SAG5 | Temp. = 37ºC, pH = 7.0, MM= 0.5%, Time= 120 h | 72.60% | Not specified | Temp. =37ºC, pH= 7.5, Glucose, beef extract | [82] |

Pseudomonas aeruginosa PAO1, Stenotrophomonasmaltophila and Proteus mirabilis | Time = 24 h, 0.5% glucose, static, temp = 37º | 67.20% | Not specified | Glucose, Nitrogen source inhibit decolorization, pH= 7, Inoculum= 15%, Temp. = 37ºC, Static condition | [45] |

Rhizoctonia sp. D-90 | Temp. = 30ºC, 125 rpm, 10 ml mycelial suspension, MM= 19.3ppm, time= 192 h, pH= 6, NaOH= 1N | 87.5% and 84.5% in molasses medium and synthetic | Adsorption mycelia culture | NaOH concentration= 5N | [49] |

Aspergillus nizer 180 | Temp. = 30ºC, 200 rpm, spores conc. = 10^10 spores | 69% | 83% color removal by biodegradation and 17% by adsorption | Sucrose (10 g/L), potassium phosphate (1 g/L), phosphate (1 g/L), magnesium salt (100 mg/L), pH=5.0 | [21] |

Phytoremediation approach

However, it is still in the experimental stage45. Kumar and Chandra effectively purified distillery wastewater by a two-step procedure including the transformation of pigment components resistant to Bacillus thuringiensis and the subsequent reduction of the effluent's residual pollutant burden by Spirodela polyrhiza53. Chandra et al. (2008) performed a comparable biphasic treatment of wastewater in a built wetland using B. thuringiensis and Typha angustifolia, resulting in a reduction of 98-99% Color, COD, and BOD after a week83.

Recent use of Potamogetonpectinatus to bioaccumulate heavy metals from distillery effluent84. In a built wetland, Typha latipholia was used to treat distillery effluent, and over the course of ten days, the BOD and COD levels were decreased by 78 and 47%, respectively85. 100 percent effluent concentration resulted in the greatest deposition of Fe in plants. Increasing concentrations of the effluent greatly decreased the plant's biomass, with plants growing in effluent concentrations of 100 percent accumulating the most Fe. A combination of Lemna minuscula and Chlorella vulgaris86 was reported to remove 52% of the colour from distillery effluent. It has been shown that microalgal treatment of wastewater may effectively remove nutrients and organic substances while simultaneously creating oxygen for use by other organisms. The macrophytes eliminated the microalgae and organic detritus from the treated wastewater by consuming them. Although it is still in the testing stage, using aquatic macrophytes to build a minimal cost treatment system is seen as a potential future area in environmental management.

Adsorption

Adsorption on activated carbon (AC) is a common physicochemical treatment method for removing colour and particular organic contaminants. Activated carbon has become an established adsorbent because of its extremely large surface area, microporosity, large capacity for adsorption, and a significant amount of surface reactivity. Prior research on the decolorization of wasted wash from a distillery has employed adsorption on commercially available and locally sourced activated carbons87-88. Bernardo et al. (1997) investigated how available for purchase activated charcoal and activated charcoal derived from sugarcane bagasse decolorized synthetic melanoidins 38. Activated charcoal was discovered by Chandra and Pandey (2000) to have a surface that had been anaerobically treated with waste wash ,having surface area around 14000 m2g-1, had considerable dye removal when treated with a fixed bed containing activated charcoal with the same surface area. With 70% of the diluted material, a nearly complete decolorization (> 99.9%) was achieved.

Coagulation and flocculation

Colloids become unstable during coagulation as a result of the forces holding them apart being neutralised. The negative charge of the colloid is balanced by positively charged cationic coagulants (zeta potential). Larger particles are created as a result of the particles colliding (flocs). Polymers help bridge the gap between bind and flocs particles into aggregates or clumps through the flocculation process. As polymer chain fragments adsorb to distinct particles, crosslinking occurs, which encourages particle aggregation. Considering the costs associated with chemicals and sludge disposal, flocculation seems to be an expensive process. Therefore, it is essential to develop cost-effective solutions for post-biomethanated wastewater. Migo et al. (1993) processed molasses wastewater with a polymer of ferric hydroxysulphate, a commercial inorganic flocculant. The effect was observed in an approximately 87% decolorization of bio-digested effluent. These results differ from those of Inanc et al. (1999), who came to the conclusion that colour removal was not possible with coagulation using alum and iron salts89. The use of lime and ozone to treat anaerobically digested wastewater was examined. The best lime dosage was determined to be 10 g/l, which led to 82.5% COD removal and 67.6% colour reduction in 30 minutes. Later, FeCl3 and AlCl3were both found to be equally successful at removing dye from biodigested waste, with a 93% decrease in colour and a 76% reduction in total organic carbon.57

Role of Enzymes in Effluent Decolourization

Enzymatic treatment is a hybrid strategy that combines physicochemical and biological methods. It provides a number of possible benefits over more traditional forms of treatment. Numerous enzymes (such as peroxidase, oxidoreductase, cellulolytic enzyme cyanidase, protease, amylase, and many more) derived from a wide range of sources play a vital role in garbage treatment. Melanoidins are able to be decolored, despite the fact that the enzyme pathway that is involved in this transformation is not completely known. Melanoidins can be decolored. White-rot fungus contain an advanced, extracellular, non-specific enzyme system that, under conditions where nutrients are in short supply, has the potential to degrade lignolytic chemicals, melanoidins, and polyaromatic compounds that are resistant to being broken down by other types of microorganisms. Intracellular enzymes that required sugar for their activity and enzymes that did not need sugar for their activity were both a part of the process of decolorization. Coriolushirsutusdemanded the involvement of peroxidases (MnP and MIP) in addition to the extracellular H2O2 produced by glucose-oxidase, while laccase played only a minimal role.. White rot is caused by a basidiomycete called T. versicolor, which is also capable of efficiently degrading humic acid and melanoidin. In order to remove colour utilising a variety of nutrients, a small inoculum consisting of homogenous pellets of the fungus T. versicolor that resemble sponges was used. The largest amount of decolorization, 82%, and the greatest reduction in N-NH4 content, 36%, were generated by using a low concentration of sucrose and KH2PO4 as the primary source of nourishment. In addition, laccase is beneficial to the process of oxidising melanoidins.

Effect of environmental factors on treatment process

There are several environmental parameters that are crucial to the microbial breakdown of industrial wastes because they have a major influence on the enzymes that function.These environmental factors include the supply of carbon, nitrogen, and phosphorus as well as pH, temperature, aeration, and inoculums dosage. The function that a variety of environmental conditions play in the process by which microorganisms degrade and remove the colour from melanoidins. According to Hayase et al 1985.study, on the hydrogen peroxide-induced destruction of melanoidins at various pH levels, melanoidin decolorization happens more quickly in alkaline pH than in acidic or neutral pH, with 94% annihilation occurring at pH 3.0-13.0. The goal of the study was to learn more about how melanoidins are destroyed by hydrogen peroxide at various pH levels. Due to the fact that melanoidins are pH-dependent, their miscibility decreases with increasing acidity compared to increasing alkalinity, and pH levels above or below pH 7.0 result in a reduction in both microbial growth and decolorization activity According to study 45 by Mohana et al. 2007, the highest decolorization took place at pH 7.0.The reason for this is that the solubility of melanoidins is pH-dependent. Both decolorization (at a rate of 80 percent) and COD removal (at a rate of 75 percent) work best at a pH level of 5. In addition to this, they found that an increase in temperature from 20 to 37 degrees Celsius increased decolorization from 35% to 67%, whereas an increase in temperature above 40 degrees Celsius had a negative effect on the denaturing capabilities of microbes. This is because the melanoidin-decolorizing capabilities of microbial cells were lost after prolonged exposure to high temperatures (>40 degrees Celsius). The temperature has an influence on the growth, metabolism, nutrition, enzymes, biomass, and permeability of membranes in living organisms. For strain D90, the ideal temperature for development and colour removal was 30 degrees Celsius, whereas the optimal temperature for Coriolus versicolor was 35 degrees Celsius, and the optimal temperature for Phanerochaetechrysosporium was 40 degrees Celsius. It is necessary to have an easily available source of carbon in order for fungus to grow and for melanoidin to be broken down. Ohmomo et al. conducted study to ascertain the contribution of different carbon and nitrogen sources on Aspergillus fumigatus G-2-maximum 6's daily activity (MDA). They made the surprising discovery that the best carbon source for melanoidin degradation is glucose.The amount of decolorization produced did not increase when more glucose than 1% was added; however, the amount of mycelial biomass did rise. Nitrogen is essential for the production of proteins and is a component of the polymers that make up cell walls. Flavodon flavus is a medium that is low in nitrogen and does a good job of decolorizing the wastewater produced by distilleries showed in table5.

Table 5: Factors influencing the decolorization by bacteria

Factors | Explanation |

pH | Melanoidin is more soluble at alkaline pH levels than at acidic pH levels, which indicates that melanoidin's solubility is pH-dependent. The ability of the bacterial consortia to multiply and degrade was adversely affected by pH values in the range of 7.0-7.5. |

Temperature | Melanoidin's solubility is pH-dependent; it is more soluble in alkaline pH than in acidic pH. The ability of the bacterial consortia to multiply and degrade was adversely affected by pH values ranging from 7.0-7.5. |

Inoculum size | Several studies found that an ideal inoculum concentration ranged from 5% to 7% (w/v), with increasing inoculum concentration increases. |

Carbon & Nitrogen Sources | In accordance with the kind of bacteria used, several carbon sources were employed. Because of its ease of usage, glucose is accepted. With regard to nitrogen sources, the same idea holds true. According to Mohana et al. 2007, organic nitrogen at a proportion of 0.05% (w/v) in distillery runoff treated anaerobically decreased decolorization and degradation. |

Shaking Speed | The decolorization process was hindered by increased shaking rates beyond 180 rpm, probably as a result of mechanical stress to bacterial cells. |

Conclusion

In the past few decades, the utilisation of microorganisms for bioremediation has gained increasing attention. Multiple microorganisms, including bacteria and fungus, have exhibited extraordinary ability to decolorize melanoidin-containing wastewater from the distillation industry. Furthermore, a better comprehension of the microbial activity required for the degradation of melanoidins would help to increase the overall effectiveness of the therapeutic system. Identification of the melanoidins' end product would be crucial throughout the deteriorating process. In the future, isolates' genetic makeup may be altered in an effort to increase their decolorization potency.As a result, it can be concluded that using microorganisms to remove colour is a workable method for creating a biotechnology solution for the remediation of distillery effluent that is both affordable and ecologically benign. In order to increase the incorporation of bacteria for the environmental remediation of industrial effluents, more technically sophisticated research is needed for studying, employing novel species of bacteria, and extending practical application. Enzymatic research will be used in the future to understand the breakdown of melanoidin.These microorganisms can be utilised in bioreactors for the treatment of wastewater and the increase of enzyme synthesis.The widespread use of these emerging innovations and the inclusion of several treatment modalities within a short future will probably make them both economically viable and successful.A group of microbiologists, biotechnologists, chemists, and engineers are essential for microbial bioremediation is ideally suited for bridging the ever-widening chasm between the numerous disciplines.

Acknowledgement

Ranjan Singh is appreciative to the department of Higher Education, Government of Uttar Pradesh, Lucknow, Uttar Pradesh, India, for the financial support under the programme “Research and Development of Uttar Pradesh State Universities” (47-2021/606/77-4-2021-/56/2020). Rajeeva Gaur is pleased to acknowledge the ministry of Higher Education, Government of Uttar Pradesh, Lucknow, India, for the financial support under the “Research and Development of Uttar Pradesh State Universities” scheme. (108/2021/2588/77-4-2021-4(28)/2021).

Conflict of Interest

The authors have no conflict of interest.

Funding Sources

Ranjan Singh is appreciative to the department of Higher Education, Government of Uttar

Pradesh, Lucknow, Uttar Pradesh, India, for the financial support under the programme “Research and Development of Uttar Pradesh State Universities” (47-2021/606/77-4-2021-/56/2020). Rajeeva Gaur is pleased to acknowledge the ministry of Higher Education, Government of Uttar Pradesh, Lucknow, India, for the financial support under the “Research and Development of Uttar Pradesh State Universities” scheme. (108/2021/2588/77-4-2021-4(28)/2021).

References

- Kulshreshtha S. Current Trends in Bioremediation and Biodegradation. J. Bioremed Biodeg. 2012; 3(7); e-114.

- Asamudo, N. U., Daba, A. S., & Ezeronye, O. U. Bioremediation of textile effluent using Phanerochaetechrysosporium. African Journal of Biotechnology. 2005; 4(13):1548-1553.

- Tyagi M. da Fonseca M.M.R., de Carvalho C.C. Bioaugmentation and Biostimulation Strategies to Improve the Effectiveness of Bioremediation Processes. Biodegradation 2011;22 (2): 231-241.

- Madhavi A. and Rao A. P. Effect of Industrial Effluent on Properties of Groundwater. Journal of Environmental Biology. 2003; 24(2) :187-192.

- Saravanamoorthy M. D., Kumari B.D.R. Effect of Textile Wastewater on Morphophysiology and Yield on two Varieties of Peanut (Arachis hypogaea L.). Journal of Agricultural Technology. 2007; 3(2):335-343.

- Subramanian K.A. Utilization of Liquid Biofuels in Automotive Diesel Engines: An Indian Perspective. Biomass and Bioenergy. 2005; 29(1): 65-72.

- Bharagava R.N. Chandra R. Effect of Bacteria Treated and Untreated Post-Methanated Distillery Effluent (PMDE) On Seed Germination, Seedling Growth and Amylase Activity in Phaseolus Mungo L. Journal of Hazardous Materials. 2010;180(1-3): 730-734.

- Wedzicha B.L., M.T. Kaputo. Melanoidins from Glucose and Glycine: Composition, Characteristics and Reactivity Towards Sulphite Ion. Food Chemistry. 1992;43(5): 359-367.

- Chowdhary P., Khan, N., & Bharagava, R. N. Distillery wastewater: it’s impact on environment and remedies. Environ Anal Ecol Stud. 2018; 1: 14-17.

- Evershed R. P. Volatile Compounds in Archaeological Plant Remains and The Maillard Reaction During Decay of Organic Matter. Science. 1997;278(5337):432-433.

- Chavan M.N. Kulkarni M.V. Zope V.P. and Mahulikar, P.P. Microbial degradation of melanoidins in distillery spentwash by an indigenous isolate. Indian Journal Biotechnology. 2006; 5:416–421.

- Painter, T. J. Carbohydrate polymers in food preservation: an integrated view of the Maillard reaction with special reference to discoveries of preserved foods in Sphagnum-dominated peat bogs. Carbohydrate polymers. 1998; 36(4): 335-347.

- Ikan, R., Dorsey, T., and Kaplan, I. R. Characterization of natural and synthetic humic substances (melanoidins) by stable carbon and nitrogen isotope measurements and elemental compositions. Analytica chimica acta. 1990; 232: 11-18.

- Brands C. M., Alink G. M. Van Boekel M. A. and Jongen W. M. Mutagenicity of heated sugar? casein systems: Effect of the Maillard reaction. Journal of Agricultural and Food Chemistry. 2000; 48(6): 2271-2275.

- Mahimairaja S., & Bolan N. S. Problems and prospects of agricultural use of distillery spentwash in India. Magnesium. 2004;1715: 2100.

- Coca M., Peña M., & González G. Chemical oxidation processes for decolorization of brown-colored molasses wastewater. Ozone: Science and Engineering. 2005; 27(5): 365-369.

- Hayase F., Bong Kim S., & Kato H. Maillard reaction products formed from D-glucose and glycine and the formation mechanisms of amides as major components. Agricultural and Biological Chemistry. 1985; 49(8): 2337-2341.

- Wijewickreme Arosha N. and David D. Kitts. Influence of Reaction Conditions on the Oxidative Behavior of Model Maillard Reaction Products. J. Agric. Food Chem. 1997; 45(12): 4571-4576.

- Monti P. M., Colby S. M., Barnett N. P., Spirito A., Rohsenow D. J., Myers, M. &Lewander, W. Brief Intervention for Harm Reduction with Alcohol-Positive Older Adolescents In A Hospital Emergency Department. Journal of Consulting and Clinical Psychology. 1999; 67(6): 989-994.

- Hodge J. E. Dehydrated Foods, Chemistry of Browning Reactions in Model Systems. J Agric Food Chem. 1953;1: 928-943.

- Miranda M. P., Benito G. G., San Cristobal N., & Nieto C. H. Color elimination from molasses wastewater by Aspergillus niger. Bioresource Technology. 1996; 57(3): 229-235.

- Cämmerer B., Jalyschkov V., & Kroh L. W. Carbohydrate structures as part of the melanoidin skeleton. In International Congress Series. 2002; 1245: 269-273.

- Sankaran K. DEPHY Project: Distillery Wastewater Treatment Through Anaerobic Digestion and Phycoremediation—A Green Industrial Approach. Renewable and Sustainable Energy Reviews. 2014. 37: 634-643.

- Chandra, R. Accumulation and Distribution of Toxic Metals in Wheat (Triticum Aestivum L.) And Indian mustard (Brassica Campestris L.) Irrigated with Distillery and Tannery Effluents. Journal of Hazardous Materials. 2009; 162(2-3): 1514-1521.

- Quesium S.Z., Siddique R.H. Preliminary observations on the river kali caused by the effluents of industrial waste. Currnt. Sci. 1960; 29:310-311.

- Venkataraman G. A note on the occurrence of large scale fish mortality along the Chaliyar River near Beypore .J Mar. Biol. Assoc. 1966; 8 (1): 224-225.

- Hingorani H.G, Divan A.D and Chandrasekhran N. Oxygen consumption in fish Labeorohita under exposition to different concentration of industrial effluents.Comp. Physiol. Ecol. 1979; 4: 272-276.

- Tewari P.K., Batra V.S. and Balakrishnan M. Water Management Initiatives in Sugarcane Molasses based Distilleries in India. Resources, Conservation and Recycling. 2007; 52(2): 351-367.

- Rafatullah, Mohd. et al. Adsorption of Methylene Blue on Low-Cost Adsorbents: A Review. Journal of Hazardous Materials. 2010; 177(1-3): 70-80.

- Oxspring, Darren A. Decolourisation And Metabolism of The Reactive Textile Dye, Remazol Black B, By an Immobilized Microbial Consortium. Biotechnology Letters. 1996; 18(5): 527-530.

- Fitzgibbon F. J., Nigam P., Singh D., & Marchant R. Biological treatment of distillery waste for pollution?remediation. Journal of Basic Microbiology. 1995; 35(5): 293-301.

- SirianuntapiboonSuntudet al. Screening of Filamentous Fungi Having the Ability to Decolorize Molasses Pigments. Agricultural and Biological Chemistry. 1988; 52(2): 387-392.

- Nandy T., Shastry S. and Kaul S.N. Wastewater Management in A Cane Molasses Distillery Involving Bioresource Recovery. Journal of Environmental Management. 2002; 65(1): 25-38.

- Kaushik S. Effect of rice straw incorporation on phytotoxicity of isoxaflutole to an exotic weed Phalaris minor Retz. Plant and soil. 2005; 277(1): 35-40.

- GargV. K., & Kaushik P. Influence of textile mill wastewater irrigation on the growth of sorghum cultivars. Applied ecology and environmental research, 6(1), 1-12.

- Peña M. Chemical Oxidation of Wastewater from Molasses Fermentation with Ozone. Chemosphere. 2003; 51(9): 893-900.

- Moosvi S., Keharia H., &Madamwar D. Decolourization of textile dye Reactive Violet 5 by a newly isolated bacterial consortium RVM 11.1. World Journal of Microbiology and Biotechnology. 2005; 21(5): 667-672.

- Bernardo E. C., Egashira R., & Kawasaki J. Decolorization of molasses' wastewater using activated carbon prepared from cane bagasse. Carbon. 1997; 35(9): 1217-1221.

- Chandra R. and Pandey P.K. Decolourisation of anaerobically treated distillery effluent by activated charcoal adsorption method. Indian Journal of Environmental Protection. 2001; 21:134-137.

- Ramteke D.S., Wate S.R. and Moghe C.A. Comparative adsorption studies of distillery waste on activated carbon. Ind. J. Envirl. Hea. 1989: 31: 17–24.

- Migo Veronica P. Decolorization of Molasses wastewater using an inorganic flocculant. Journal of Fermentation and Bioengineering.1993; 75(6): 438-442.

- Beltrán Fernando J., Manuel González, and Juan F. González. Industrial Wastewater Advanced Oxidation. Part 1. UV Radiation in the presence and absence of hydrogen Peroxide. Water Research. 1997; 31(10): 2405-2414.

- Dhale A.D. and Mahajani V.V. Studies in treatment of disperse dye waste: Membrane–Wet Oxidation Process. Waste Management. 2000; 20(1): 85-92.

- Sirianuntapiboon S., Phothilangka P., &Ohmomo S. Decolorization of molasses wastewater by a strain No. BP103 of acetogenic bacteria. Bioresource Technology. 2004; 92(1):31-39.

- Mohana S., Desai C., &Madamwar D. Biodegradation and decolourization of anaerobically treated distillery spent wash by a novel bacterial consortium. Bioresource Technology. 2007; 98(2): 333-339.

- Pant D., &Adholeya A. Biological approaches for treatment of distillery wastewater: a review. Bioresource technology. 2007; 98(12) : 2321-2334.

- Aoshima I., Tozawa Y., Ohmomo S., & Ueda K. Production of decolorizing activity for molasses pigment by Coriolus versicolor Ps4a. Agricultural and biological chemistry. 1985; 49(7); 2041-2045.

- Ohmomo S., Kaneko Y., Sirianuntapiboon S., Somchai P., Atthasampunna P., & Nakamura I. Decolorization of molasses waste water by a thermophilic strain, Aspergillus fumigatus G-2-6. Agricultural and biological chemistry. 1987; 51(12): 3339-3346.

- Sirianuntapiboon S., Sihanonth P., Somchai P., Atthasumpunna P., Hayashida S.. Mechanism for melanoidin decolourization by Rhizoctonia sp. D–90. Biosci. Biotech. Biochem.1991; 59:1185–1189.

- Ohmomo S., Kainuma M., Kamimura K., Sirianuntapiboon S., Aoshima I., &Atthasampunna P. Adsorption of melanoidin to the mycelia of Aspergillus oryzae Y-2-32. Agricultural and biological chemistry. 1988; 52(2): 381-386.

- Nakajima-Kambe T., Shimomura M., Nomura N., Chanpornpong T., & Nakahara T. Decolorization of molasses wastewater by Bacillus sp. under thermophilic and anaerobic conditions. Journal of bioscience and bioengineering. 1999; 87(1): 119-121.

- Sharma R., Sharma G., & Sharma E. Energy efficiency of large cardamom grown under Himalayan alder and natural forest. Agroforestry systems. 2002; 56(3): 233-239.

- Kumar P., & Chandra R. Decolourisation and detoxification of synthetic molasses melanoidins by individual and mixed cultures of Bacillus spp. Bioresource Technology. 2006; 97(16): 2096-2102.

- Nataraj S. K., Hosamani K. M., &Aminabhavi T. M. Distillery wastewater treatment by the membrane-based nanofiltration and reverse osmosis processes. Water Research. 2006; 40(12): 2349-2356.

- Ghosh M. Ganguli A. Tripathi A.K. Treatment of anaerobically digested distillery spent wash in a two-stage bioreactor using Pseudomonas putida and Aeromonas sp. Process Biochemistry.2003;7:857–862.

- Moriya K., Iefuji H., Shimoi H., Sato S. I., &Tadenuma M. Treatment of distillery wastewater discharged from beet molasses-spirits production using yeast. Journal of Fermentation and Bioengineering.1990; 69(2); 138-140.

- Sowmeyan R. Swaminathan G. Effluent Treatment Process in Molasses Based Distillery Industries: A Review. Journal of Hazardous Materials. 2008; 152-453.

- Pena M, Gonzalez G, San N, Nieto H. Color elimination from molasses wastewater by Aspergillus niger. Bioresour Technol. 1996;57:229–235.

- Dahiya J., Singh D., Nigam P. Decolorization of synthetic and spent wash melanoidins using the white rot fungus Phanerochaetechrysosporium JAG-40. Bioresour. Technol. 2001a; 78: 95–98.

- Dahiya J., Singh D., Nigam P. Decolorization of molasses waste water by cells of Pseudomonas Xuroscens immobilized on porous cellulose carrier. Bioresour. Technol. 2001b; 78: 111–114.

- Kumar S., & Viswanathan L. Production of biomass, carbon dioxide, volatile acids, and their interrelationship with decrease in chemical oxygen demand, during distillery waste treatment by bacterial strains. Enzyme and microbial technology. 1991; 13(2): 179-187.

- Adikane H. V., Dange M. N., & Selvakumari K. Optimization of anaerobically digested distillery molasses spent wash decolorization using soil as inoculum in the absence of additional carbon and nitrogen source. Bioresource technology. 2006; 97(16): 2131-2135.

- Benito G.G., Miranda M.P., Santos D.R. Decolorization of wastewater from an alcoholic fermentation process with Trametes Versicolor. Bioresource Technology. 1997; 61(1): 33-37.

- Jain N., Minocha A.K. and Verma C.L. Degradation of predigested distillery effluent by isolated bacterial strains. Ind. J. Exp. Bot. 2002; 40:101-105.

- Knapp, J. S. Use of wood-rotting fungi for the decolorization of dyes and industrial. Fungi in bioremediation. 2001; 23: 242-245.

- Jimenez J. L., Jayne J. T., Shi Q., Kolb C. E., Worsnop D. R., Yourshaw I. & Davidovits P. Ambient aerosol sampling using the aerodyne aerosol mass spectrometer. Journal of Geophysical Research: Atmospheres. 2003; 108(D7).

- Watanabe Y., Sugi R., Tanaka Y., &Hayashida S. Enzymatic decolorization of melanoidin by Coriolus sp. No. 20. Agricultural and biological chemistry. 1982; 46(6): 1623-1630.

- Miyata N., Mori T., Iwahori K., Fujita M. Microbial decolorization of melanoidins containing wastewaters: combined use of activated sludge and the fungus Coriolushirsutus. J BiosciBioeng. 2000;89:145–150.

- Pant D and Adholeya A. Biological approaches for treatment of distillery waste water: a review. Bioresour Technol. 2007; 98:2321–2334.

- Raghukumar C., Mohandass C., Kamat S., Shailaja M.S. Simultaneous detoxification and decolorization of molasses spent wash by the immobilized White Rot Fungus Flavodon flavus isolated from a marine habitat. Enzyme and Microbial Technology. 2004; 35: 197-202.

- Raghukumar C., Mohandass C., Kamat S., Shailaja M.S. Simultaneous detoxification and decolorization of molasses spentwash by the immobilized white-rot fungus Flavadon flavus isolated from the marine habitat. EnzymMicrob Technol. 2004; 35:197–202.

- Angayarkanni J., Palaniswamy M., Swaminathan K. Biotreatment of distillery effluent using Aspergillus niveus. Bull. Environ. Contam. Toxicol. 2003; 70: 268-277.

- Shayegan J., Pazouki M., Afshari A. Continuous decolorization of anaerobically digested distillery wastewater. Process Biochem. 2005; 40: 1323-1329.

- Federici F. Potential applications of viable, immobilized fungal cell systems. World Journal of Microbiology and Biotechnology. 1993; 9(5): 495-502.

- Sumino T, Kon M, Mori N, Nakajima K (1985) Development of wastewater treatment technique by immobilized microorganisms. J Water .Waste 27:52-57.

- Anselmo A.M., Novais J.M. Bioteehnol. Letters. 1984; 6: 601-606.

- Livernoche D., Jurasek L., Desrochers M., Dorica J., & Veliky I. A. Removal of color from kraft mill wastewaters with cultures of white?rot fungi and with immobilized mycelium of Coriolus versicolor. Biotechnology and Bioengineering. 1983; 25(8): 2055-2065.

- Kowalska M., Bodzek M., &Bohdziewicz J. Biodegradation of phenols and cyanides using membranes with immobilized microorganisms. Process Biochemistry. 1998; 33(2): 189-197.

- Zache G., & Rehm H. J. Degradation of phenol by a coimmobilized entrapped mixed culture. Applied microbiology and biotechnology. 1989; 30(4): 426-432.

- Shah S.S., Desai J.D., Ramakrishna C., Bhatt N.M., Aerobic biotreatment of wastewater from dimethyl terephthalate plant using biomass support particles. J. Ferment. Bioeng. 1998; 86: 215–219.

- Yadav S., & Chandra R. Biodegradation of organic compounds of molasses melanoidin (MM) from biomethanated distillery spent wash (BMDS) during the decolorization by a potential bacterial consortium. Biodegradation. 2012; 23(4): 609-620.

- Santal A.R., Singh N.P., Saharan B.S. Biodegradation and detoxification of melanoidin from distillery effluent using an aerobic bacterial strain SAG5 of Alcaligenes faecalis. Journal of Hazardous Materials. 2011; 193: 319-324.

- Chandra R., Yadav S., Bharagava R. N., & Murthy R. C. Bacterial pre-treatment enhances removal of heavy metals during treatment of post-methanated distillery effluent by Typha angustata L. Journal of environmental management. 2008; 88(4): 1016-1024.

- Singh N. K., Pandey G. C., Rai U. N., Tripathi R. D., Singh H. B., & Gupta D. K. Metal accumulation and ecophysiological effects of distillery effluent on Potamogetonpectinatus L. Bulletin of environmental contamination and toxicology. 2005; 74(5): 857-863.

- Trivedy R. K., & Nakate S. S. Treatment of diluted distillery waste by using constructed wetland. Indian Journal of Environmental Protection. 2000; 20(10): 749-753.

- Valderrama L. T., Del Campo C. M., Rodriguez C. M., de-Bashan L. E., & Bashan Y. Treatment of recalcitrant wastewater from ethanol and citric acid production using the microalga Chlorella vulgaris and the macrophyte Lemna minuscula. Water research. 2002; 36(17): 4185-4192.

- Satyawali Y. and M. Balakrishanan. Wastewater treatment in molasses-based alcohol distilleries for COD and colour removal: A review. J.Environ. Manag. 2008; 86: 481-497.

- Satyawali Y. and M. Balakrishanan: Treatment of distillery effluent in a membrane bioreactor (MBR) equipped with mesh filter. Separation and Purification Technology. 2008; 63: 278-286.

- Inanc B., Matsui S., & Ide S. Propionic acid accumulation in anaerobic digestion of carbohydrates: an investigation on the role of hydrogen gas. Water science and technology. 1999; 40(1): 93-100.

Abbreviations

AS, Activated sludge system; BOD5, biochemical oxygen demand; COD, chemical oxygen demand; GST, glutathioneS-transferase; MP, melanoidin pigment; MWW, molasses wastewater, stillage; MYGPA, malt extract-yeast extract-glucose-peptone agar; MYGPA-MP, malt extract-yeast extract-glucose-peptone agar containing MP; MYGPB, malt extract-yeast extract-glucose-peptone broth; MYGPB-MP, malt extract-yeast extract-glucose-peptone broth containing MP; PCR, polymerase chain reaction; SDS, Sodium Dodecyl sulphate; SCP, single cell protein; SWW, synthetic wastewater; SWW-MP, synthetic wastewater containing MP; U-MWW, untreated molasses wastewater.