Embodied Energy and Thermal Performance of Alternate Walling Materials in Affordable Housing in the Composite Climate of Delhi

1

Department of Architecture,

School of Planning and Architecture,

New Delhi,

India

Corresponding author Email: gunjan.jain@spa.ac.in

Copy the following to cite this article:

Jain G, Manchanda S, Singh M. Embodied Energy and Thermal Performance of Alternate Walling Materials in Affordable Housing in the Composite Climate of Delhi. Curr World Environ 2024;19(1).

Copy the following to cite this URL:

Jain G, Manchanda S, Singh M. Embodied Energy and Thermal Performance of Alternate Walling Materials in Affordable Housing in the Composite Climate of Delhi. Curr World Environ 2024;19(1).

Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-11-13 |

|---|---|

| Accepted: | 2024-03-01 |

| Reviewed by: |

Faradiba

Faradiba

|

| Second Review by: |

Nahedh Taha Al-Qemaqchi

Nahedh Taha Al-Qemaqchi

|

| Final Approval by: | Dr. Hemant kumar |

Introduction

It is estimated by UN-Habitat that by 2030, 40 percent of the world's population will require adequate housing options 1. Most of this demand is going to be in the global South 2. Adding to the required large housing stock in a short time will result in increased demand for raw materials 3 and more time-concentrated emissions 4 adversely impacting the environment. The residential building sector accounts for 30 to 50% of the material consumption and is expected to expand further with the rising global population 5. The operation of residential buildings and related services contributes to 22% of global energy use and 17% of energy-related carbon emissions 4.

The building construction industry in India is growing at 8% per annum and is one of the largest consumers of natural resources 6. There is a huge disparity in the demand and supply of urban housing in India with 96 percent lying in the affordable category for the economically weaker section (EWS) of society 7,8. The anticipated demand for affordable housing in India is 38 million housing units by 2030 from 18.78 million in 20127, generating more demand for construction materials. Also, the residential sector will have the largest electricity consumption by 2030 9 mainly due to the addition of new construction and more indoor space cooling demand 10. The affordable housing stock in India primarily runs in ‘naturally ventilated’ mode and uses fans for comfort during the peak hot and humid months 11,12. Improper design and insensitive use of construction materials in naturally ventilated buildings lead to uncomfortable indoor conditions which may lead to loss of productivity9 or certain health conditions and in the case of economic affordability retrofits with space cooling or heating devices 13. Thus, it is imperative to evaluate the thermal comfort provided by the building envelope, of which the walling systems form a major part. It is also important to examine the embodied energy of these materials as the widespread use of energy-heavy materials has detrimental environmental impacts 6. The Government of India is encouraging the use of alternate building materials to cover the huge affordable housing shortage in urban areas 14. Along with ensuring that the proposed alternate materials are low on embodied energy, it is equally important to ensure that they provide thermal comfort to the users.

The present study presses the need for consideration of both embodied energy and thermal performance of the building envelope in naturally ventilated affordable housing in India for environmentally and socially sustainable development. It presents an analysis of the initial embodied energy requirement and thermal performance of fly ash bricks, Autoclaved Aerated Blocks (AAC) blocks and Reinforced Cement Concrete (RCC) precast panels as alternate walling options compared to conventional burnt clay brick walling system in the composite climate zone of Delhi. A detailed understanding of these materials in terms of their initial energy requirements and their thermal performance during the operational phase would help government agencies to make environmentally and socially conscious decisions about the use of alternate walling materials on a large scale in providing adequate affordable shelter for the marginalized.

Related Literature

The embodied energy of a built form signifies the total energy expended in the use of building materials and the construction process. This includes the cumulative energy utilized in the processing, manufacturing, and transportation of building materials, energy used during construction on-site, maintenance works, and demolition at the end of life 15. Embodied energy comprises 11- 20% of the total energy consumed across the life of a building as established by multiple studies on residential buildings built with conventional construction techniques 16, 17,18,19. Out of this, embodied energy for on-site construction/ fabrication, transportation of materials to the site, or demolition of a building is only 1-2% of the total energy consumed during the life of a building. The widely used construction materials such as bricks, cement, steel, and RCC account for nearly 98% of the total embodied energy in a building 16,17,20–22.

In the context of low-energy-consuming buildings, embodied energy is anticipated to constitute a significant portion of the overall life cycle energy. Operational energy consumption decreases with improved energy efficiency measures, which can cause an increase in embodied energy due to the burden of the additional materials required to achieve the same. In a few cases, 31% of the total energy of the entire life of a building is comprised of embodied energy and in a few it even exceeds life cycle operational energy 15,19,23–25. Affordable housing options are low-operational energy buildings that rely on natural ventilation and passive measures like suitable orientation, windows, shading devices, and the use of fans in summer to provide comfortable indoor conditions 13. The use of alternate building materials in the construction of mass affordable housing can avoid locking up huge energy as embodied energy of the materials and the construction process. Alternate building materials use renewable energy or resources, utilize agricultural or industrial waste in production, or are produced through mechanized or semi-mechanized processes for speed and quality than conventional materials 14. For example, AAC blocks are three times lighter and cover more area in the same weight than burnt clay brick and use almost 55% less cement and sand 26. Fly Ash bricks or blocks are low-density materials, low on embodied energy, as it is made of waste residue from coal-based thermal power plants. It is economical along with reasonably good strength and a smooth finish27. Another example of alternate construction technology is the precast concrete construction system, which is a factory-based, high-speed, mass-manufacturing of customized structural and wall components assembled on-site with cranes and other equipment. All the components are joined through on-site concreting along with embedded reinforcement to ensure monolithic behavior. This type of construction is fast with less wastage of materials, controlled quality, and can be undertaken in all weathers. RCC walls can be precast or cast on-site as a monolithic construction. In monolithic construction, all walls with openings, and slabs are cast in situ in RCC using modular formwork made up of aluminum or plastic. It enables fast construction of multiple similar units with a casting cycle of two to five days per floor and is hence suitable for mass housing. It provides a durable, earthquake-resistant structure with a smooth finish that requires no plastering and thus reduces the quantity of materials being used otherwise in conventional construction methods 14.

Thermal comfort is the psychological state in which occupants are content with their immediate surrounding temperature conditions 28. It depends on indoor air temperature, radiant temperature, humidity levels, and air velocity in a built form. It also depends on the individual's metabolic rate due to various activities conducted in the space and the type of attire worn 29. Indian National Building Codes (NBC) 2005 specified the comfort temperature range as 26-32°C, for only the air-conditioned buildings, based on international standards 30. The international thermal comfort standards ASHRAE 55 and ISO 7730 are grounded on climate chamber-based Fanger's model of Predicted Mean Vote (PMV)- Percentage Predicted Dissatisfied (PPD) model 13. However, studies have proven that the PMV and PPD thermal comfort model overestimates comfort expectations as experienced by the Indian population living in naturally ventilated built forms wherein, they adapt to varying climate conditions across seasons 13,30–32 . An adaptive thermal comfort model combines behavioral adjustments, physiological acclimatization, and psychological expectation to suggest an acceptable indoor temperature range to a reference outdoor temperature (Tout-rep) 31. The revised NBC 2016 proposes determining indoor comfort temperature based on the outside running mean temperature 30. The neutral temperature in naturally ventilated buildings ranges from 19.6°C to 28.5 °C considering 30-day outdoor running mean air temperatures between 12.5 to 31 °C as per India Model for Adaptive Comfort (IMAC 2014)32. IMAC-R 2022 for naturally ventilated residential buildings prescribes the indoor operative temperature (OT) range acceptable by 80% and 90% of Indian population in relation to the outdoor reference temperature. The neutral temperature range suggested by IMAC-R 2022 is higher than the neutral temperatures given by IMAC 2014 for naturally ventilated buildings by 2.1 oC 31.When air velocity is less than 0.2m/s and there is a small difference in ambient air temperature and radiant temperature, the operative temperature can be computed as the average of air and mean radiant temperature 29. EN 15251 and comfort model indices gives ‘discomfort degree-hours criteria’ based on the sum of hourly exceedances of operative temperature outside a stipulated comfort range. Summer discomfort considers occupied hours exceeding the upper limit while winter discomfort focuses on hours below the lower limit. Annual discomfort degree hours contain both summer and winter periods 33.

Thermal comfort in naturally ventilated housing is dependent on occupant behavior, indoor environment, and the characteristics of the envelope 31. Most of the studies in the literature have explored the embodied energy aspect of the envelope 11,15–20,22,23,25,34–37. Few studies have considered both embodied energy and thermal performance of the materials together in the selection of the appropriate building envelope12.

The present research work aims to explore whether the use of emerging alternate walling materials in place of conventional walling system can save on the initial embodied energy and provide more thermal comfort to the users during the use phase. The objective of the research work is to assess the performance in terms of the percentage of embodied energy saving and percentage of thermal performance efficiency by replacing conventional burnt clay brick walling system with alternate walling materials viz. fly ash bricks, AAC blocks and RCC precast panels in the composite climate zone of Delhi.

The scope of the work is limited to initial embodied energy calculations (A1-A3 stage) and thermal performance analysis of the walling assembly. The research strictly investigates the effect of alternate walling materials on the initial energy use and thermal comfort by keeping the other parameters of the roofing material, window sizes, window glass, shading devices etc constant as built in a typical EWS housing unit in the region as per standard construction practices prescribed by Central Public Works Department (CPWD), Government of India.

Materials and Methods

The present research work follows the steps as enumerated: a) selection of alternate walling materials for study through literature, stakeholders survey and interview of the experts; b) understanding the Window Floor Area Ratio (WFR), Window Wall Area Ratio (WWR), window type, type of window glass, shading devices, etc in a typical EWS housing unit in the region through construction drawings and EWS housing survey of two identified housing complexes; c) understanding the occupancy schedule, window opening schedule, and energy consumption pattern in a typical EWS housing in the region through EWS housing household survey of one of the housing complexes; d) development of a 3D model for simulation and its validation through onsite measurements. e) conducting thermal simulations of alternate walling systems considering parameters of RCC roof, 4mm clear glass, etc constant as found in a typical EWS housing built in the region; f) embodied energy calculations for alternate walling systems.

The conventional construction practice for mid-rise to high-rise residential buildings, in Delhi-NCR and most of the cities in India, is cast in-situ RCC frame buildings with burnt brick infill walls and cast in-situ RCC slab 14,38. A survey of 106 stakeholders (95% confidence level and a margin of error of 10%) comprising of architects, engineers, developers, building technology researchers active in the construction industry in Delhi NCR region was conducted in 2021-2022. The survey was conducted to identify in practice and emerging construction technologies in the region and reasons for selection of the technologies for housing construction. The results of the survey were validated by multiple rounds of interview with six identified experts in the field. The part results of the survey were published by the first author as a part of the ongoing study in 2022 39. Results show that the prevailing use of walling materials other than bricks is largely lightweight fly ash bricks and AAC blocks. This is facilitated by the abundance of fly ash from coal-based power plants in the region and it is the Government's mandate to use these materials in public works. Additionally, precast concrete construction system is gaining popularity in the housing market due to speed, cost and quality 14,38,39.

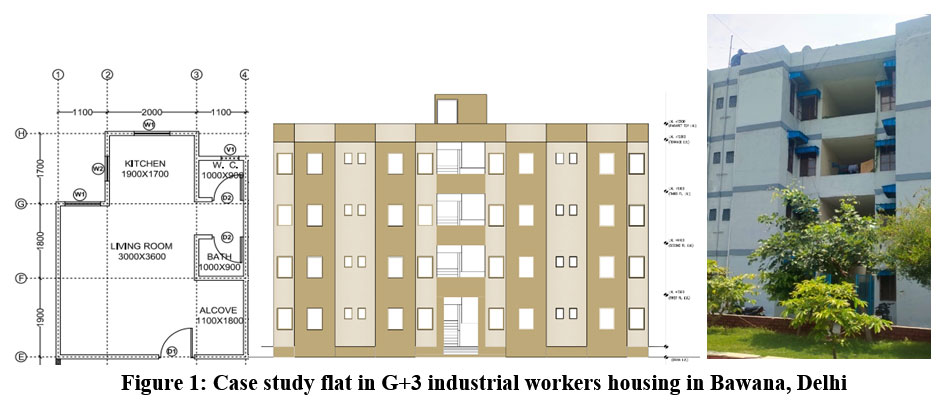

An analysis of unit design was conducted for two EWS housing complexes in Bawana, north-west part of Delhi, comprising of one-room and two-room flats to understand the factors affecting energy consumption viz. window sizes, WWR, WFR, and shading devices. Both housing blocks are G+3 structures having casement windows with 4mm float glass and a 90% openable area-to-opening ratio. Both the units were found to have WWR and WFR within the Bureau of Energy Efficiency (BEE), Government of India, guidelines for residential buildings for composite climates ensuring natural ventilation and daylighting 40. One of the analyzed units was selected as the case study flat, as shown in Figure 1. The chosen flat is in an adverse location on the top floor with a southwest orientation in the industrial workers’ housing (DSIDC) complex in Bawana, Delhi. The housing block is in an urban setting with similar ground plus three-storey housing blocks around it with normal shading. A household survey of around 52 houses, 10% of a total 512 houses in the selected housing complex, was done in May 2022 to understand the occupancy schedule, window opening schedule at different times of the day and the household electrical fixtures and appliances used on a typical summer day.

| Figure 1: Case study flat in G+3 industrial workers housing in Bawana, Delhi.

|

The housing block is simulated in Design Builder v7.0.1.6 utilizing typical meteorological year weather data, a synthesized single year of weather data that represents historical weather data for 30 years (1992 to 2021), to get reliable results over a single year's data, which may be influenced by unforeseen weather variations. The weather data used in the research has been developed for cities in India at the unprecedented resolution of 25km under the Zed-i project by the University of Bath, UK (Zed-i data)41 for facilitating the simulation work in the field of building design and energy use. The window opening schedule, occupancy schedule in a day, and the internal load of household fixtures and appliances were put in for the simulations as per the information from the household survey. For validation of the model, on-site measuring instruments were put in two flats, as per the available access and permissions. One of the chosen flats is made of RCC walls with RCC roof and the other is of burnt clay brick with RCC roof in the same microclimatic region of Bawana, Delhi. Thus, the first set of experimental simulations was carried out for burnt clay brick (base case) and RCC walls with RCC roof on the developed Design Builder model. Instruments were set on the topmost floor of G+3 housing in the southwest room, the worst orientation for heat gain in the tropical zone. It was ensured that both the flats are in similar height housing blocks and have similar window-to-wall ratio and window-to-floor ratio, orientation, and surrounding shading conditions. Outside and inside air temperature, relative humidity, and inside globe temperature were measured using Ellitech RC-4HC and GSP-6 data loggers for the peak summer month of May 2023 at hourly intervals. Testo 425 Anemometer was used to take spot readings for air velocity with the fan on at different speeds. The indoor mean radiant temperature and the operative temperature (OT) were calculated from the on-site measured values for the summer month of May 2023 as per ISO 7726, 1998. In the hourly data comparison of the OT values for burnt clay brick walls and RCC walls by the simulated results and the measured data for May 2023, the Mean Bias Error (MBE) was 2% and 5% respectively and the Root Mean Square Error (RMSE) was 14% and 22% respectively. These are below the ASHRAE Guideline of 10% MBE and 30% RSME for hourly data 43. Hence the generated software model is validated and sufficiently reliable to generate further simulation results. The other alternate walling options of AAC blocks and fly ash bricks are also analyzed in comparison to the base case on the model for thermal performance in naturally ventilated mode. The operative temperature achieved in the interiors with each walling option is compared with the comfort range suggested by IMAC-R 2022 to derive the analysis for the discomfort degree hours. The embodied energy values per cubic meter are compared for each wall assembly from cradle to gate (lifecycle stages A1 to A3 as per EN 15978). The embodied energy coefficients of different materials are taken from literature44.

Results and Discussion

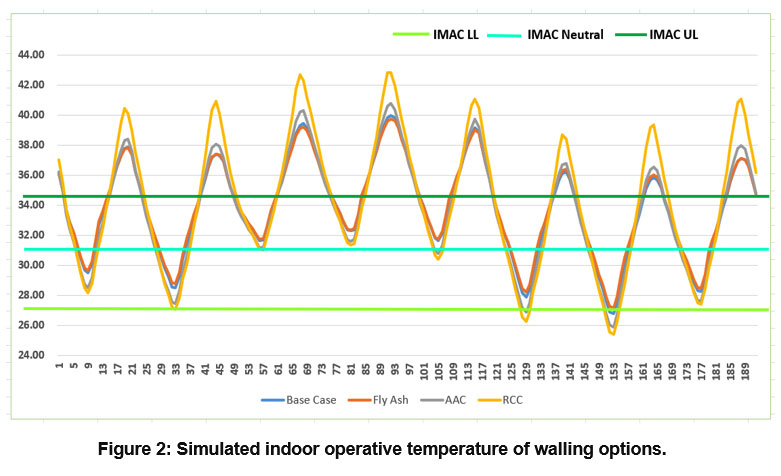

The difference in the indoor operative temperature (OT) of the case study flat with each walling option during the summer week of May in Delhi is shown in Figure 2. The indoor OT in each case is compared with IMAC-R 2022 thermal acceptability comfort temperature range. It is evident from the graph that burnt clay brick and fly ash walling materials are performing very similarly and are closer to the IMAC-R 80% upper limit to the 30-day running mean of the outside temperature. The OT achieved by AAC masonry is higher than the base case and fly ash. However, the RCC wall is performing the worst with indoor OT much higher than the IMAC-R 80% upper limit to the 30-day running mean of outside temperature.

| Figure 2: Simulated indoor operative temperature of walling options.

|

Table 1 given below gives the annual discomfort degree hours and summer discomfort degree hours by comparing the simulated indoor operative temperatures of each walling material with IMAC-R 2022 thermal acceptability comfort range. It is evident from the table that discomfort degree hours are highest for the RCC wall and least for the fly ash bricks wall. Compared to the burnt clay brick case, annual discomfort is 33% and 15% higher for the RCC and AAC blocks walling construction respectively. The summer discomfort is phenomenally 65% higher in case of RCC walls and 9% higher in case of the ACC blocks wall w.r.t to the base case. Fly ash bricks are performing better, 1-3 % less discomfort than the base case.

Table 1: Annual and Summer Discomfort Degree hours of walling options

| Burnt Clay Brick (Base Case) | AAC Blocks | Flyash Bricks | RCC wall (precast) |

Annual Discomfort degree hours | 17,984.54

| 20,711.57

| 17,380.79

| 23,879.28

|

Summer Discomfort Degree hours | 5,377.40

| 5,869.01

| 5,326.37

| 8,875.70

|

Table 2 below gives the quantity of material used in the various walling options in the case study flat along with the embodied energy coefficients from International Finance Corporation (IFC), a member of the World Bank Group, database 45 and the total embodied energy per cubic meter for each walling option. It is evident from the table that embodied energy is extremely high for the RCC wall and least for the fly ash bricks, closely followed by AAC blocks. Burnt clay bricks also exhibit significantly higher embodied energy than fly ash bricks and AAC blocks.

Table 2: Total Embodied Energy (EE) of walling options

| Walling Material | Quantity (Kg) | EE (MJ/Kg) | Total EE (MJ) | Total EE (MJ/m3) |

Base Case | Burnt Clay Brick (230mm x115mm x75mm) | 13488.65 | 6.5 | 87676.27 |

9652.87

|

Cement Mortar (1:6) | 3859.25

| 1.1 | 4245.18

| ||

Cement Plaster (10mm internal 1:6; 15mm external 1:4) | 2213.87

| 4.8 | 102548.06

| ||

| 132955.62 | ||||

1 | AAC Blocks (600mm x100mm x 200mm) | 4413.528061

| 3.7 | 16330.05

|

3112.19

|

Cement Mortar (1:6) | 2094.065314 | 1.1 | 2303.47

| ||

Cement Plaster (10mm internal 1:6; 15mm external 1:4) | 2213.87

| 4.8 | 10626.60

| ||

| 29260.13 | ||||

2 | Flyash Brick (230mm x115mm x75mm) | 11591.81

| 0.83 | 9621.20

|

2,203.88

|

Cement Mortar (1:6) | 3859.25 | 1.1 | 4245.18 | ||

Cement Plaster (10mm internal 1:6; 15mm external 1:4) | 2213.87

| 4.8 | 10626.61

| ||

| 2305.53 | ||||

3 | RCC wall (precast) (3000mm x 3000mm x 100mm) |

|

|

|

6584.03

|

Cement Concrete (M30) | 11311.13 | 2.6 | 29408.95 | ||

Steel reinforcement | 152.33

| 30 | 4570.15 | ||

| 33979.11 | ||||

Conclusion

The study explored the embodied energy and thermal performance of the various walling options namely fly ash bricks, AAC blocks, and RCC wall (precast) which are considered alternatives to the conventional burnt clay brick and are prevalent in use in Delhi and its surrounding region. The government and the industry are actively promoting these walling alternatives as sustainable building materials 14,46. The use of AAC blocks is mandated in the affordable houses constructed under PMAY (U). The use of fly ash bricks is also mandated by the Government in public projects. The monolithic RCC construction is also being promoted under PMAY(U) and is being undertaken in one of the model projects 46.

The results of this study strengthen the fact that fly ash bricks can be used as a sustainable alternate material being low on embodied energy and thermal discomfort. Burnt clay bricks have lower thermal discomfort than AAC blocks, however, due to the very high embodied energy that goes into fuel consumption in kilns, burnt clay bricks are less preferred than AAC blocks. Burnt clay bricks have the highest per cubic meter embodied energy amongst all the walling materials examined. In terms of embodied energy AAC blocks perform better than burnt clay bricks. However, care should be taken that fly ash is available in the region for the production of the bricks and AAC blocks and is not being transported over large distances. The study strongly discourages the use of RCC walls whether precast or in-situ as in monolithic construction in the composite climate. RCC wall is performing the worst with high annual and summer discomfort. It has high embodied energy also due to its constituent materials, mainly due to the use of steel reinforcement. The high speed, replicability in execution, and hence the low-cost aspect of this construction cannot overlook the high embodied energy and high thermal discomfort associated with the construction of RCC walls in the composite climate. The findings of the study are in line with various earlier Indian studies that have also focused on one or more of the above-discussed materials in a similar or different context 12,15,17,22,23,27,34–36. The study strongly advocates the consideration of both embodied energy and thermal performance aspects of the building envelope before adopting and mainstreaming alternate walling systems on a large scale in affordable housing in India.

Acknowledgements

The first author expresses gratitude to the School of Planning and Architecture (SPA), New Delhi, for granting permission to conduct the Ph. D research work, a part of its findings is being presented here. The Department of Architecture, SPA New Delhi is acknowledged for guiding the research work.

Conflict of Interest

There is no conflict of interest.

Funding Source

There is no funding or financial support for this research work.

Authors’ Contribution

This is the research work of the Principal Author conducted as a part of the Ph. D study. The co-authors are the supervisors.

Data Availability Statement

The manuscript incorporates all datasets produced or examined throughout this research study.

Ethics Approval Statement

The study does not involve any experiment on humans and animals.

References

- Kawamura S, Brady C. Sustainable and Affordable Housing, Spotlighting Action from across the World Green Building Council Network.; 2023. Accessed November 9, 2023. https://worldgbc.org/wp-content/uploads/2023/05/C22.9056-WGBC_Affordable-Housing-Report_Master-2.pdf

- Mahendra A, King R, Du J, et al. Towards a More Equal City: Seven Transformations for More Equitable and Sustainable Cities. World Resources Institute. Published online 2021. doi:10.46830/wrirpt.19.00124

CrossRef - Marinova S, Deetman S, van der Voet E, Daioglou V. Global construction materials database and stock analysis of residential buildings between 1970-2050. J Clean Prod. 2020;247. doi:10.1016/j.jclepro.2019.119146

CrossRef - United Nations Environment Programme. 2020 Global Status Report For Buildings and Construction?:Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector.; 2020. http://www.un.org/Depts/

- Steger S, Bleischwitz R. Drivers for the use of materials across countries. J Clean Prod. 2011;19(8):816-826. doi:10.1016/j.jclepro.2010.08.016

CrossRef - Venkatarama Reddy B V. Sustainable materials for low carbon buildings. International Journal of Low-Carbon Technologies. 2009;4(3):175-181. doi:10.1093/ijlct/ctp025

CrossRef - Palayi A, Priyaranjan N, Mukherjee A. Affordable Housing in India. RBI Bulletin. Published online 2018. Accessed November 9, 2023.

https://rbidocs.rbi.org.in/rdocs/Bulletin/PDFs/AFFORDABLE609D506CB8C247DAB526C40DAF461881.PDF - Ministry of Housing and Urban Affairs, Government of India. Accessed November 9, 2023. https://www.mygov.in/group/ministry-housing-and-urban-affairs/

- NITI Aayog. A Report on Energy Efficiency and Energy Mix in the Indian Energy System (2030),Using India Energy Security Scenarios,2047.; 2015. Accessed November 9, 2023. https://www.gita.org.in/Attachments/Reports/Energy_Efficiency.pdf

- Graham P, Rawal R. Achieving the 2°C goal: the potential of India’s building sector. Building Research and Information. 2019;47(1):108-122. doi:10.1080/09613218.2018.1495803

CrossRef - Shukla Y, Rawal R, Shnapp S. Residential Buildings in India: Energy Use Projections and Savings Potentials.; 2015. Accessed November 9, 2023.

https://www.researchgate.net/publication/280312420_Residential_Buildings_in_India_Energy_Use_Projections_and_Savings_Potentials - Sen R, Bhattacharya SP, Chattopadhyay S. Are low-income mass housing envelops energy efficient and comfortable? A multi-objective evaluation in warm-humid climate. Energy Build. 2021;245. doi:10.1016/j.enbuild.2021.111055

CrossRef - Thapa S, Indraganti M. Evaluation of thermal comfort in two neighboring climatic zones in Eastern India—an adaptive approach. Energy Build. 2020;213. doi:10.1016/j.enbuild.2020.109767

CrossRef - BMTPC SND. Alternate & Innovative Construction Systems for Housing. (BMTPC, SPA New Delhi, eds.). I.K. International Pvt Ltd; 2021.

- Praseeda KI, Reddy BVV, Mani M. Embodied and operational energy of urban residential buildings in India. Energy Build. 2016;110:211-219. doi:10.1016/j.enbuild.2015.09.072

CrossRef - Singh S, Chani PS, Kulkarni SY. Energy Assessment of Multi-Storied Apartments in Roorkee. International Journal of Engineering and Technology. 2012;4(6):684-688. doi:10.7763/ijet.2012.v4.462

CrossRef - Ramesh T, Prakash R, Kumar Shukla K. Life Cycle Energy Analysis of a Multifamily Residential House: A Case Study in Indian Context. Open Journal of Energy Efficiency. 2013;02(01):34-41. doi:10.4236/ojee.2013.21006

CrossRef - Atmaca A, Atmaca N. Life cycle energy (LCEA) and carbon dioxide emissions (LCCO2A) assessment of two residential buildings in Gaziantep, Turkey. Energy Build. 2015;102:417-431. doi:10.1016/j.enbuild.2015.06.008

CrossRef - Mehta S, Chandur A, Palaniappan S. Life Cycle Energy Assessment of a Multi-storey Residential Building. Journal of The Institution of Engineers (India): Series A. 2017;98(1-2):155-162. doi:10.1007/s40030-017-0205-3

CrossRef - Debnath A, Singh S V, Singh P. Comparative Assessment of Energy Requirements for Different Types of Residential Buildings in India. Vol 23.; 1995.

CrossRef - Adalberth K. Energy Use during the Life Cycle of Buildings: A Method. Vol 32.; 1997.

CrossRef - Bardhan S. Embodied energy analysis of multi storied residential buildings in urban India. WIT Transactions on Ecology and the Environment. 2011;143:411-421. doi:10.2495/ESUS110351

CrossRef - Praseeda KI, Reddy BVV, Mani M. Embodied energy assessment of building materials in India using process and input-output analysis. Energy Build. 2015;86:677-686. doi:10.1016/j.enbuild.2014.10.042

CrossRef - Noori M, Gregory JR, Olivetti EA, Greene S. Life Cycle Assessment for Residential Buildings: A Literature Review and Gap Analysis Rev. 1 TATA Waste Systems project at Muzaffarnagar View project Effect of cool pavements on building energy demand View project. Published online 2016. doi:10.13140/RG.2.2.10238.38722

- Praseeda KI, Venkatarama Reddy B V., Mani M. Embodied and operational energy of rural dwellings in India. International Journal of Sustainable Energy. 2019;38(3):227-237. doi:10.1080/14786451.2017.1418742

CrossRef - Kamal Arif M. Analysis of autoclaved aerated concrete(AAC) blocks with reference to its potential and sustainability. JBuildMaterStruct. 2020;7:76-86. doi:10.34118/jbms.v7i1.707

CrossRef - Singh V, Behl V, Dahiya V. Comparison of Fly Ash Based (AAC) Block and Clay Bricks for Structure and Strength Properties. In: Journal of Physics: Conference Series. Vol 1950. IOP Publishing Ltd; 2021. doi:10.1088/1742-6596/1950/1/012074

CrossRef - ASHRAE. Thermal Environmental Conditions for Human Occupancy: ANSI/ASHRAE Addendum d to ANSI/ASHRAE Standard 55-2017.; 2020. www.ashrae.org

- Kazkaz M, Pavelek M. Operative Temperature and Globe Temperature. Engineering MECHANICS. 2013;20(3/4):319-325. Accessed November 10, 2023. http://www.engineeringmechanics.cz/pdf/20_3_319.pdf

- Sansaniwal SK, Mathur J, Garg V, Gupta R. Review of studies on thermal comfort in Indian residential buildings. Sci Technol Built Environ. 2020;26(6):727-748. doi:10.1080/23744731.2020.1724734

CrossRef - Rawal R, Shukla Y, Vardhan V, et al. Adaptive thermal comfort model based on field studies in five climate zones across India. Build Environ. 2022;219:109187. doi:10.1016/j.buildenv.2022.109187

CrossRef - Manu S, Shukla Y, Rawal R, Thomas LE, de Dear R. Field studies of thermal comfort across multiple climate zones for the subcontinent: India Model for Adaptive Comfort (IMAC). Build Environ. 2016;98:55-70. doi:10.1016/j.buildenv.2015.12.019

CrossRef - Carlucci S, Pagliano L. A review of indices for the long-term evaluation of the general thermal comfort conditions in buildings. Energy Build. 2012;53:194-205. doi:10.1016/j.enbuild.2012.06.015

CrossRef - Bansal D, Singh R, Sawhney RL. Effect of construction materials on embodied energy and cost of buildings - A case study of residential houses in India up to 60 m2 of plinth area. Energy Build. 2014;69:260-266. doi:10.1016/j.enbuild.2013.11.006

CrossRef - Reddy BVV, Jagadish KS. Embodied energy of common and alternative building materials and technologies. Energy Build. 2003;35(2):129-137. doi:10.1016/S0378-7788(01)00141-4

CrossRef - Kumar A, Chani PS, Deoliya R. Low embodied energy sustainable building materials and technologies. Key Eng Mater. 2015;650:13-20. doi:10.4028/www.scientific.net/KEM.650.13

CrossRef - Venkatarama Reddy B V. Sustainable materials for low carbon buildings. International Journal of Low-Carbon Technologies. 2009;4(3):175-181. doi:10.1093/ijlct/ctp025

CrossRef - BMTPC. Compendium of Green Technologies in Mass Housing Projects for “Composite” Climatic Zones of India Covering Regions of Punjab, Haryana, Delhi-NCR.; 2016. Accessed November 10, 2023. https://www.gkspl.in/wp-content/uploads/2018/10/BMTPC-green-technology-for-mass-housing-compendium-06.05.2016.pdf

- Jain G, Singh M, Sarkar S. Development of a framework for assessing energy efficiency of the alternative construction techniques in the housing sector. ECS Trans. 2022;107(1):11215-11224. doi:10.1149/10701.11215ecst

CrossRef - BEE. Eco-Niwas Samhita 2018 (Energy Conservation Building Code for Residential Buildings) Part I: Building Envelope.; 2018.

CrossRef - zed-i data.

- ISO 7726. Ergonomics of the Thermal Environment-Instruments for Measuring Physical Quantities.; 1998. https://standards.iteh.ai/catalog/standards/sist/99f92eea-d1b3-48b4-8a3c-

- ASHRAE 14. ASHRAE Guideline: Measurement of Energy and Demand Savings.; 2002.

- IFC, World Bank Group. India Construction Materials Database of Embodied Energy and Global Warming Potential METHODOLOGY REPORT.; 2017. www.ifc.org

- India Construction Materials Database of Embodied Energy and Global Warming Potential:Methodology Report.; 2017. www.ifc.org

- MoHUA. PMAY(U), MoHUA. Published 2023. Accessed November 10, 2023. https://pmay-urban.gov.in/