Heavy and toxic metals analysis from effluent of paper mill, based on cotton comber and cotton linter raw materials

Vibha Agrawal1 * and S.A. Iqbal2

1

Department of Chemistry,

Gyan Ganga Institute of Technology and Management,

Bhopal,

India

2

Department of Chemistry,

Safia College of Science and Education,

Bhopal,

462 001

India

DOI: http://dx.doi.org/10.12944/CWE.3.1.29

The present study deals with effluent analysis of a paper mill using cotton comber and cotton linter as raw material for paper manufacturing process. The effluents generated at different stages were collected. The fibrous sludge samples recovered in different section of mill were also collected. The inorganic parameters i.e. alkalinity, hardness, sulphate, chloride, phosptahe, sodium, potassium, iron, copper, nickel, mercury etc., were estimated. The heavy metal content of the untreated and treated effluents and the sludge samples are determined by the atomic absorption spectrophotometer. The inorganic parameters as well as heavy metal analysis results were interpreted and compared with the permissible limits.

Copy the following to cite this article:

Agrawal V, Iqbal S.A. Heavy and toxic metals analysis from effluent of paper mill, based on cotton comber and cotton linter raw materials. Curr World Environ 2008;3(1):185-188 DOI:http://dx.doi.org/10.12944/CWE.3.1.29

Copy the following to cite this URL:

Agrawal V, Iqbal S.A. Heavy and toxic metals analysis from effluent of paper mill, based on cotton comber and cotton linter raw materials. Curr World Environ 2008;3(1):185-188. Available from: http://www.cwejournal.org/?p=803

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2008-04-04 |

|---|---|

| Accepted: | 2008-06-09 |

Introduction

The paper mills generate large quantity of effluents as a consequence of pulping and bleaching processes. Most of the paper mills use non-wood (bamboo, baggage and straw etc.) Hard wood, (Casuarina, Eucalyptus etc.) and soft wood as fibrous raw material for paper manufacturing.

The paper mills extract the cellulose fiber from the above raw materials in the pulping process. During this pulping process a large quantity of black liquor is generated. The main constituent of which is the lignin which is responsible for the color, biochemical oxygen demand and chemical oxygen demand of the effluents. The paper mill also uses bleaching chemicals generally chlorine based compoundss for the improvement of brightness of paper. The effluent generated from the bleach plant therefore has more adsorbable organic halide (AOX) and total organic chloride (TOCl). Hence conventional paper mill effluents even after proper treatments cause more pollution to the nearby water bodies and at the same time cause of organic and inorganic pollution.

The effluents analyzed and estimated in this study, are quite different from the effluents of other conventional paper mills, are here the raw material used are comber and linter having minimum impurities.

In the present study the effluents have no lignin and are therefore free from adsorbable organic halide and total organic chloride, therefore in the first step, inorganic parameters and heavy metals contents of effluents were studied, the results were interpreted and compared for quality of water suitable for irrigation and for further reutilization in the paper making process.

Experimental

Collection of Sample

The effluent generated from various process of the mill is segregated into two streams. Out of which the main effluent generated by the washing of fiber, refining and from machine backwater which is generally called white water. The other stream generated from the washing of digester house is called black and yellow liquor. Both the samples were collected separately and also tested separately. The fiber sample recovered after the treatment of white water and also the sludge generated from the black and yellow liquor plant also collected and tested separately. The effluent samples were collected in the incubated plastic bottles.

|

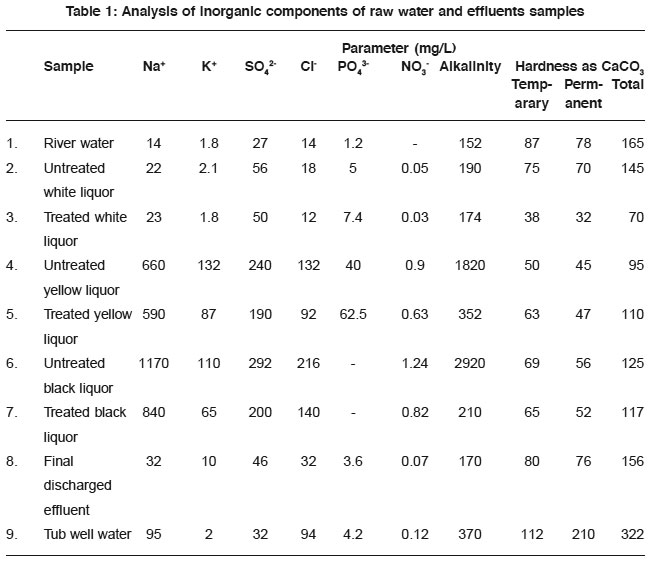

Table 1: Analysis of inorganic components of raw water and effluents samples Click here to view table |

Analysis of Parameters

The sodium and potassium were estimated by using flame photometer, sulphate chlroride and phosphate are determined by following quantitative analysis method. The alkalinity and hardness were determined by following standard procedure for water analysis process. The heavy metals content of effluent apart from Na+ and K+ ions other heavy metals like iron, lead, mercury, copper, nickel, zinc were also detected and suitably estimated, using, atomic, absorption spectrophotometer.

|

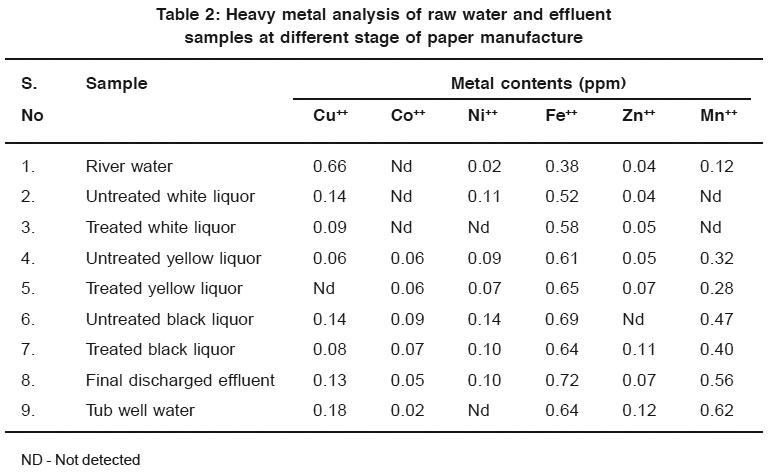

Table 2: Heavy metal analysis of raw water and effluent samples at different stage of paper manufacture Click here to view table |

|

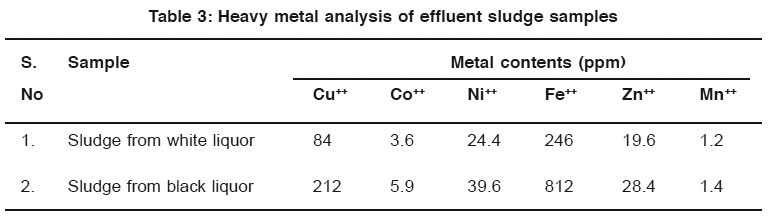

Table 3: Heavy metal analysis of effluent sludge samples Click here to view table |

Results and Discussion

The results of table 1 show that the Na+ and K+ concentration in the treated black and yellow liquor are more. The same may be due to caustic treatment during washing/bleaching process of the raw material. It is observed that the same value is less in the treated sample that may be due to the deposition of sludge in the treatment process. However the value of the sample that may be due to the same for the final treated discharged water sample is 32 ppm and 10ppm respectively which is under standard range. The value of Na+ of final treated discharged sample is much lower than the Na+ concentration of tube well water i.e. 95ppm. The results of sulphate, chloride and also nitrate black and yellow liquor are slightly more, that reflect the caustic treatment and washing during the process and may also be due to the more hardness of water of Narmada near Hoshangabad. But the values for the final treated discharged samples is very less as compared to the effluents for the final treated paper mills.

|

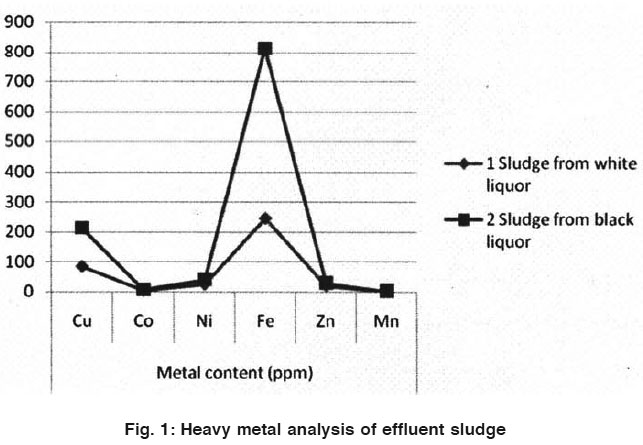

Figure 1: Heavy metal analysis of effluent sludge Click here to view figure |

Alkalinity of treated samples in the similar trend. The total hardness of final treated discharged water sample is almost matching with the river Narmada water sample and are much lower than the tube well samples. Results of Table 2 shows that the heavy metals are present in the effluent sample. But the results of the heavy metals are well within standard limits. The results show lower heavy metal content in effluent sample than effluents of conventional paper mills. The results also indicate that except Fe and Cu all the heavy metal content of finally treated discharged sample is less than the water sample of tube well. The low heavy metal content may be due to inherent character of comber linter raw material or may also be due to cheap quality chemicals used during the paper manufacturing process. Table 3 shows both the sludge contain heavy metals. The concentration of Cu and Fe is slightly on the higher side. This may be due to the wear and tear or rusting of the equipments of plant. This may be also be due to very old and absolute equipments and machineries. However the results are almost within the standard limits.

Conclusion

The analysed results indicate that the nature of these effluents is totally different from other paper making mills. The heavy metal content as well as inorganic constituents are well within the standard limit. There are no harmful ingredients present in the mill effluent. The only limitation is that the effluent is slightly turbid. From the metal analysis point view, the effluent sample is tolerable and can be safely used for the irrigation purpose and can also be reutilized in the process of paper making after reducing the turbidity of the water.

References

- "Approved methods for the physical and Chemical examination of water" Second Ed. Institute of water engineering, London (1953).

- Cook, R.A. TAPPI Environmental Conference Proceedings, TAPPI Press, Atlanta, (1992) p. 1055.

- Shrivastava Brajesh, K. and Masood Alam, Current World Environment, (2006) 1(2).

- Shah Mayur, C., The comparative study of water quality parameters of ground water among the 3 regions of Kalol Taluka Gujarat, Current World Environment, (2006) 1.

- Singh, R.M. and Trivedi, R.K. Primary water quality of Tawa Reservoir for designated best use". Journal of Pollution Research, Enviro- Media, Karad, 3rd. (2005).

- Trivedi, R.K. and Goal, P.K. Chemical and biological methods for water pollution studies, Environmental publishing, Karad, (1987).