Environment-Friendly Refrigerants for Sustainable Refrigeration and Air Conditioning: A Review

1

Department of Mechanical Engineering,

DSEU Pusa Campus (Formerly Pusa Institute of Technology),

Delhi Skill and Entrepreneurship University,

New Delhi

India

2

Department of Electrical Engineering,

DSEU Pusa Campus (Formerly Pusa Institute of Technology),

Delhi Skill and Entrepreneurship University,

New Delhi

India

Corresponding author Email: s.bhatti21877@gmail.com

DOI: http://dx.doi.org/10.12944/CWE.18.3.03

Copy the following to cite this article:

Bhatti S. S, Kumar A, Reetu R, Singh R. Environment-Friendly Refrigerants for Sustainable Refrigeration and Air Conditioning: A Review. Curr World Environ 2023;18(3). DOI:http://dx.doi.org/10.12944/CWE.18.3.03

Copy the following to cite this URL:

Bhatti S. S, Kumar A, Reetu R, Singh R. Environment-Friendly Refrigerants for Sustainable Refrigeration and Air Conditioning: A Review. Curr World Environ 2023;18(3).

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2023-06-25 |

|---|---|

| Accepted: | 2023-09-01 |

| Reviewed by: |

Aleksandar Racz

Aleksandar Racz

|

| Second Review by: |

Faradiba

Faradiba

|

| Final Approval by: | Dr. R K Aggarwal |

Introduction

Refrigeration and air conditioning systems play a vital role in numerous industries, such as food preservation, healthcare, comfort cooling, and industrial operations. These systems utilize refrigerants for heat transfer and cooling.1 Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs) were historically extensively used as refrigerants due to their favourable properties, including stability, minimal toxicity, and high energy efficiency. However, the discovery of their negative environmental effects has necessitated the development of substitute refrigerants.2,3 It has been determined that CFCs and HCFCs contribute to ozone depletion and global warming by releasing chlorine and bromine atoms into the stratosphere. The Montreal Protocol, which was implemented in 1987, aimed to eradicate the production and consumption of substances that contribute to the depletion of the ozone layer.4–6

The major environmental protection-related agreements related to refrigerants are shown in Table 1. The Montreal Protocol and the Kyoto Protocol have been implemented to address environmental issues such as ozone layer depletion and global warming. The Kigali Amendment to the Montreal Protocol was adopted in 2016 to phase down HFCs. The need to resolve the environmental impact of conventional refrigerants and comply with international regulations motivates the development of environmentally benign refrigerants.7,8 The search for alternative refrigerants with reduced environmental impact is motivated by a number of significant factors, including ODP, GWP, Safety Considerations and Thermodynamic properties.

Table 1: Environment protection-related agreements for refrigerants

Agreement | Year | Major Results |

Montreal Protocol | 1987 | Gradual elimination ozone-depleting substances (ODSs). To phase out CFC |

Kyoto Protocol to the United Nations Framework Convention on Climate Change (UNFCCC) | 1997 | Reduction of greenhouse gas emissions |

Paris Agreement | 2015 | To phase out CFCs |

Kigali Amendment to the Montreal Protocol | 2016 | Phase-down of hydrofluorocarbons (HFCs) and HFOs introduced. |

Ozone depletion is a significant environmental concern because it increases the penetration of the sun's hazardous ultraviolet (UV) radiation, which can have negative effects on human health and ecosystems.9,10 Environmentally beneficial refrigerants should have low or no ozone depletion potential (ODP), thereby minimizing ozone depletion.11,12 Global warming potential is the ability of a substance, relative to carbon dioxide (CO2), to retain heat in the atmosphere over a specific time period. The high GWP values of traditional refrigerants, including CFCs and HCFCs, contribute to the greenhouse effect and climate change. In order to mitigate their effect on global warming, environmentally beneficial refrigerants should have a significantly lower GWP.13,14

In addition to environmental considerations, the safety of refrigerants is of the utmost importance. Some conventional refrigerants are extremely toxic or combustible, posing hazards to human health and safety. To ensure safe operation in refrigeration and air conditioning systems, environmentally benign refrigerants should exhibit lower toxicity and lower flammability.15 The efficacy and performance of refrigeration and air conditioning systems are directly affected by the thermodynamic properties of refrigerants. To ensure efficient and dependable operation, environmentally friendly refrigerants must possess desirable thermodynamic properties, such as appropriate boiling and condensing temperatures, heat transfer coefficients, and volumetric capacity.16

The background of the research conducted in this review article is based on the following premises:

- Refrigeration and air conditioning are essential for numerous applications, including industrial operations, comfort cooling, medicinal storage, and food preservation.

- The use of conventional refrigerants in these systems has negative effects on the environment, including ozone depletion and global warming.

- There is a demand for environmentally friendly refrigerants with good thermophysical, thermodynamic, environmental and safety characteristics as well as minimal or negligible ODP and GWP. These properties influence the performance and acceptability of environment friendly refrigerants.

- Based on their chemical composition, environmentally friendly refrigerants can be divided into natural and synthetic categories.

- The introduction and deployment of environmentally friendly refrigerants in refrigeration and air conditioning systems present numerous challenges and opportunities.

Methodology

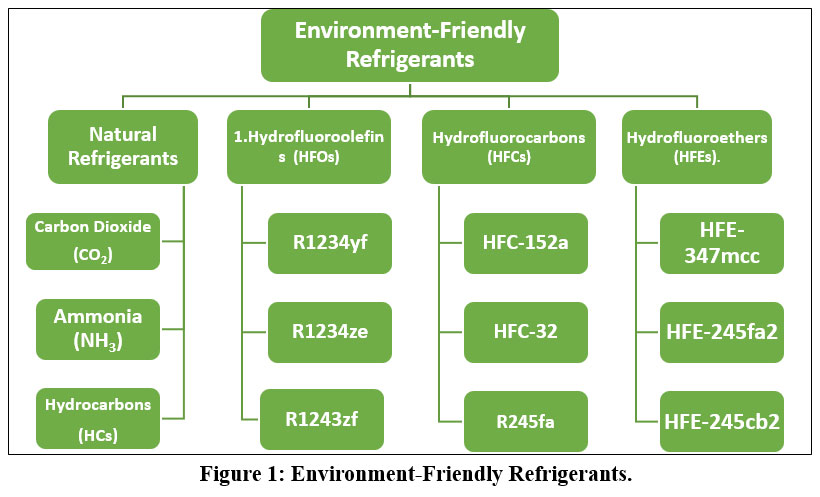

This review study examines the emerging field of environmentally friendly refrigerants. Firstly, environmental impact of traditional refrigerants is discussed. The second part is an overview of the criteria for choosing environmentally friendly refrigerants. The third part reviews the applications of environmentally friendly refrigerants that comprise natural refrigerants (NH3, CO2, hydrocarbons), hydrofluoroolefins (HFOs), ultra-low GWP hydrofluorocarbons (HFCs), hydrofluoroethers (HFEs), and combinations or blends of these refrigerants. The next section of the paper focuses on emerging technologies, aim to develop alternatives that are more efficient, environmentally sustainable, and energy-conserving. In subsequent section safety Safety Considerations and Regulatory framework is discussed. Final section addresses the Challenges and future directions for implementation of environmentally friendly refrigerants.

Environmental Impact of Traditional Refrigerants

The capacity of a material to obliterate ozone molecules in the stratosphere is referred to as ozone depletion potential. Chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), two common refrigerants, have been recognized as significant ozone depletion culprits. Chlorine atoms, which are present in CFCs, are discharged into the stratosphere once they reach the high atmosphere. When these chlorine atoms are released, they can catalytically destroy ozone molecules, causing the ozone layer to weaken. HCFCs nevertheless have the ability to deplete the ozone layer, although being less dangerous than CFCs. They have the ability to degrade ozone molecules since they include chlorine and fluorine atoms. To safeguard the ozone layer, the Montreal Protocol gradually phased out the manufacturing and use of CFCs and HCFCs.16–18

Also, traditional refrigerants, have high GWP values, including CFCs and HCFCs. In contrast to carbon dioxide (CO2) over a given time period, CFC-12, which is frequently used in older refrigeration systems, has a GWP of 10,900, suggesting that it significantly contributes to global warming. Despite having lower GWP values than CFCs, HCFCs nevertheless have an impact on global warming. A common refrigerant with a GWP of 1,810 is HCFC-22. These high GWP values highlight the need for alternative refrigerants with lower global warming potential.19,20

Environmentally Friendly Refrigerant Selection Criteria

Ozone Depletion Potential (ODP)

The ODP of a refrigerant is one of the most important criteria for ecologically acceptable refrigerants. ODP gauges a substance's capacity to annihilate stratospheric ozone molecules. The less hazardous a refrigerant is to the ozone layer, the lower its ODP value. In order to have a minimum or zero ODP, environmentally friendly refrigerants should be used.21

Global Warming Potential (GWP)

Another important factor for selecting ecologically friendly refrigerants is GWP. The greenhouse warming potential (GWP) measures a substance's capacity to trap heat in the atmosphere of the planet and hence influence climate change. Low-GWP refrigerants aid in reducing the effect of air conditioning and refrigeration on global warming. GWP values for environmentally friendly refrigerants need to be considerably lower than those for conventional refrigerants like CFCs and HCFCs.22

Toxicity and Flammability

Beyond their effects on the environment, refrigerants are also subject to safety issues. When evaluating a refrigerant's appropriateness, toxicity and flammability are crucial factors. Refrigerants considered environmentally friendly should be less harmful and provide fewer threats to human health and safety. They should also have minimal flammability to enable safe operation in refrigeration and air conditioning systems.

To evaluate refrigerants' toxicity and flammability properties, extensive testing and assessment is done. While flammability is normally examined using flammability limits, ignition energy requirements, and flame propagation characteristics, toxicity is typically analyzed using exposure limits and associated health risks.23,24

| Figure 1: Environment-Friendly Refrigerants.

|

Environmentally Friendly Refrigerants

Natural Refrigerants

Natural refrigerants have drawn much interest as safe substitutes for conventional refrigerants. They stand out for their minimal potential for global warming, non-ozone-depleting qualities, and low or no environmental effect. Ammonia (NH3), hydrocarbons (HCs), and carbon dioxide (CO2) are three frequently utilized natural refrigerants.25

Carbon Dioxide (CO2)

Since many years ago, carbon dioxide (CO2), a naturally occurring substance, has been utilized as a refrigerant. As a result of its zero GWP rating, it is a very ecologically friendly choice. Compared to conventional systems, CO2 refrigeration systems run at greater pressures, which might create certain design and safety concerns. However, technological developments have improved the effectiveness and viability of CO2 systems for a range of uses, including industrial refrigeration, cold storage, and supermarkets.26

Because it is inexpensive, non-toxic, and inflammable, CO2 is a secure option for refrigeration applications. A further factor in the sustainability of the industry is the CO2 byproduct, which may be trapped and used as a refrigerant.

Ammonia (NH3)

Another popular natural refrigerant with outstanding thermodynamic qualities is ammonia (NH3). It is one of the most ecologically responsible alternatives because it has no ozone depletion potential and a GWP value of 0. For many years, NH3 has been employed in large-scale air conditioning, cold storage, and industrial refrigeration. Ammonia is extremely energy-efficient, has great heat transport capabilities, and uses little power. Ammonia is poisonous; thus, it must be handled carefully and with safety measures to guarantee proper functioning. Ammonia dangers must be managed with the use of proper system design, leak detection, and ventilation.27

Hydrocarbons (HCs)

Propane (R-290) and isobutane (R-600a), two hydrocarbons (HCs) that are naturally occurring substances, are low-GWP and ozone-depleting refrigerants. Small household refrigeration systems, vending machines, and commercial refrigeration equipment often employ HCs. They are very energy efficient and have good thermodynamic characteristics. Although hydrocarbons are extremely effective and have little influence on the environment, they are combustible and need for special safety precautions. To guarantee the secure use of hydrocarbon refrigerants, proper system design is required, including trustworthy leak detection and ignition prevention techniques.28–30

Hydrofluoroolefins or HFOs

A novel family of refrigerants called hydrofluoroolefins (HFOs) has gained appeal as an alternative to conventional refrigerants that is less harmful to the environment. HFOs are made with strong thermodynamic characteristics while having a low global warming potential (GWP). The HFOs 1234yf and 1234ze are two HFOs that are often utilized.31 The necessity to solve the environmental issues with conventional refrigerants, especially those with high GWP, led to the invention of HFOs. In an effort to lessen greenhouse gas emissions and slow down climate change, HFOs were created. GWP is significantly lower for these refrigerants than it was for their predecessors, such as hydrofluorocarbons (HFCs). HFOs were created in an effort to balance performance and environmental effects. In accordance with worldwide legislation and activities focused on decreasing greenhouse gas emissions, HFOs minimize the impact of refrigeration and air conditioning systems to global warming by lowering the GWP.32–34

HFOs have advantageous performance traits that make them suited for a range of uses. They have thermodynamic characteristics that are comparable to those of conventional refrigerants, enabling effective heat transmission and cooling. In refrigeration and air conditioning systems, HFOs also work well with the current machinery and lubricants, minimizing the need for significant transitional alterations. HFOs are created with minimal toxicity and either nil or low flammability in mind when it comes to safety. As a result, there are potentially fewer threats to human health and safety when using conventional refrigerants. To maintain safe operation and avoid any mishaps, it is still crucial to handle HFOs with the proper safety precautions and to adhere to approved recommendations.

When working with HFOs, proper system design, including leak detection and maintenance, is essential to ensuring their safe and effective usage. To reduce any possible dangers, it is advisable to adhere to the standards and instructions provided by manufacturers and regulatory agencies for the safe handling and use of HFOs.35,36

Hydrofluorocarbons (HFCs)

Synthetic refrigerants called hydrofluorocarbons (HFCs) were created to replace ozone-depleting compounds like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs). HFCs possess a substantial GWP and actively contribute to the phenomenon of climate change. even if they do not destroy the ozone layer. To lessen their environmental effect, attempts have been undertaken to find low-GWP substitutes and blends/mixtures. Low-GWP HFC substitutes have been created in response to the demand for more ecologically acceptable refrigerants. These substitutes are designed to offer HFC-like thermodynamic features and performance with markedly less influence on global warming. HFC-32 (GWP of 675) and HFC-152a (GWP of 138) are two examples of low-GWP HFC substitutes. In comparison to conventional HFCs like HFC-134a (GWP of 1,430) and HFC-410A (GWP of 2,088), these substitutes offer a significant reduction in GWP while keeping effective cooling capabilities.37–39 These refrigerants are suitable for various applications such as chillers, heat pumps, air conditioners and refrigerators.40,41 A transitional road to more environmentally friendly refrigeration and air conditioning systems is made possible by the use of low-GWP HFC substitutes. By lowering greenhouse gas emissions linked to HFCs and adhering to international agreements and laws intended to lessen carbon footprint, they contribute to preventing climate change.

Blends and combinations have also been created to lessen the environmental effect of HFCs in addition to low-GWP HFC substitutes. These mixtures, which often include several refrigerants with complementing characteristics, enable for better performance and a lower GWP than individual HFCs. For instance, ozone-depleting chemicals have frequently been replaced by refrigerant mixes like R-407C and R-410A. Blends and combinations provide a balance between environmental factors, system compatibility, and energy efficiency. It is feasible to attain desirable qualities while lowering the GWP by blending several refrigerants. These precisely mixed refrigerants are designed for specific applications in order to maximize performance and guarantee safe operation. The environmental effect and safety of blends and mixes should still be assessed based on their composition, consumption, and application-specific needs even though they may have a lower GWP.

Hydrofluoroethers (HFEs).

These are synthetic refrigerants that have zero ODP and low to medium GWP. They are also non-flammable and have good thermal stability and compatibility with materials. Some examples of these refrigerants are R-E347mcc, R-E245fa2 and R-E245cb2. These refrigerants are mainly used as solvents, blowing agents and heat transfer fluids, but they can also be used as refrigerants for low-temperature applications42–44.

Table 2: Environmentally Friendly Refrigerants Properties, GWP, ODP and Applications

Refrigerant | Type | Properties | GWP | ODP | Applications | Reference |

R717 (ammonia) | Natural | High efficiency, high toxicity, high flammability, low cost | 0 | 0 | Industrial refrigeration, heat pumps, chillers | 45–48 |

R744 (carbon dioxide) | Natural | High efficiency, high pressure, low toxicity, low flammability, low cost | 1 | 0 | Supermarket refrigeration, heat pumps, transport refrigeration | |

R290 (propane) | Natural | High efficiency, low pressure, low toxicity, high flammability, low cost | 3 | 0 | Domestic refrigeration, commercial refrigeration, air conditioning | |

R1234yf (HFO-1234yf) | HFO | Low efficiency, low pressure, low toxicity, low flammability, high cost | 4 | 0 | Automotive air conditioning, chillers | 49–51 |

R1234ze (HFO-1234ze) | HFO | Low efficiency, low pressure, low toxicity, low flammability, high cost | 6 | 0 | Commercial refrigeration, air conditioning | |

R32 (HFC-32) | HFC | Medium efficiency, medium pressure, low toxicity, non-flammable, medium cost | 677 | 0 | Automotive air conditioning, domestic refrigeration | 52–55 |

R152a (HFC 152a) | HFC | High efficiency, high pressure, low toxicity, non-flammable, medium cost | 138 | 0 | Air conditioning | |

R-E347mcc (HFE-347mcc) | HFE | Low efficiency, low pressure, low toxicity, non-flammable, high cost, low heat of vaporization, medium specific volume, low thermal conductivity, high Prandtl number | 9.5 | 0 | Solvent, blowing agent, heat transfer fluid | 56,57 |

R-E245fa2 (HFE-245fa2) | HFE | Low efficiency, low pressure, low toxicity, non-flammable, high cost, medium heat of vaporization, medium specific volume, low thermal conductivity, high Prandtl number | 9.7 | 0 | Solvent, blowing agent, heat transfer fluid | |

R-E245cb2 (HFE-245cb2) | HFE | Low efficiency, low pressure, low toxicity, non-flammable, high cost, medium heat of vaporization, medium specific volume, low thermal conductivity, high Prandtl number | 10.1 | 0 | Solvent, blowing agent, heat transfer fluid |

Mixtures and blends of environmentally friendly refrigerants

In recent years, there have been several research conducted to explore the utilization of mixtures and blends as a means to enhance the performance of environmentally friendly refrigerants. Padmavathy et al 58 evaluates low-GWP refrigerants as environmentally friendly alternatives to R134a in low-temperature applications. Comparatively analyzing operational efficiency of R1234ze/R134a, R1234yf/R134a, R1234ze/R32, and R1234yf/R32, aims to identify sustainable alternatives. The 90:10 blend of R1234ze and R134a showed superior performance, making it a viable option for lower-temperature applications. Mohanraj & Abraham 59 studied eco-friendly refrigerant options for automobile air conditioners, including HFCs, HFOs, hydrocarbons, CO2, composite mixed refrigerants, and nano refrigerants. Hydrocarbon refrigerants are recommended due to their favorable properties. The utilization of natural refrigerants and their mixtures by Mohapatra et al. 60 has been observed to be a successful strategy in mitigating the negative environmental impacts linked to chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) refrigerants. This adoption not only enhances the dependability and durability of refrigeration systems but also helps to protect the environment.

In a study conducted by Kumma et al 61 it was reported that low GWP refrigerant mixtures are potential replacements for traditional R134a and R22 refrigerants in compact refrigeration units. These mixes are non-flammable, have zero ozone depletion potential, and have low global warming potential. Natural refrigerants and combinations mitigate environmental consequences associated with CFC and HCFC refrigerants, enhancing refrigeration systems' dependability and durability while protecting the environment. To mitigate environmental impacts, it is crucial to use refrigerants with low GWP and enhanced energy efficiency. However, many zero- ODP and low GWP alternatives have unfavorable attributes, such as increased flammability, toxicity, or reduced volumetric capacity. The study conducted by Uddin & Saha 62 recommends that HFC and HFO mixtures, specifically R32/R1234yf, R32/R1234ze, and R32/R1123, show potential as viable alternatives for replacing existing refrigerants. The study also reported that R744/R32/R1234ze(E) and R744/R32/R1234yf as favourable ternary refrigerant mixtures.

Farooq et al 63 studied HFO refrigerants and reported that R1234ze(Z) exhibits desirable thermodynamic properties, as evidenced by its low Global Warming Potential (GWP) value of 7. Consequently, it can be considered as a viable substitute refrigerant for refrigeration systems, contributing to the promotion of environmental sustainability. Another study was undertaken by Nair64 on the topic of HFO refrigerants reported that compared to the coefficient of performance (COP) seen with R134a, the operational efficiency of environmentally friendly refrigerants R1234yf and R1234ze(E) in practical refrigeration systems showed a modest loss in COP. However, HFO-R1234yf has been recommended as a feasible alternative to R134a. Bhatti et al 65 found that the incorporation of environmentally friendly refrigerants in vapour absorption technology, which harnesses waste heat from engines, offers several benefits in terms of energy preservation for cooling systems and contributes to the reduction of greenhouse gas emissions.

For sustainable refrigeration and air conditioning, hydrofluoroolefins (HFOs) and natural refrigerants having potential, in reducing greenhouse gas emissions within the refrigeration and air conditioning sector. The examples of cities and countries that have adopted or expressed their intention to adopt different environment friendly refrigerants, such as New York City, California, Japan, China, India, and Europe. Furthermore, it has been established that refrigerant blends demonstrate non-flammability, possess an ODP of zero, and possess low levels of GWP. The application of natural refrigerants and their mixtures has been observed to yield significant benefits in terms of minimizing the environmental impacts linked to chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) refrigerants. The implementation of this approach not only contributes to the improvement of reliability and longevity in refrigeration systems, but also plays a crucial role in preserving and protecting the environment.66

Emerging Technologies and Refrigerants

Several cutting-edge technologies and refrigerants are being investigated as the need for ecologically friendly refrigerants rises. The goal of these technologies is to create substitutes that are more effective, environmentally friendly, and energy efficient. Phase-change materials (PCMs), nano refrigerants, and ionic liquids are three noteworthy new technologies in this area.

Ionic liquids

A type of salts known as ionic liquids may be found at room temperature in a liquid condition. Considering their special qualities, such as low vapour pressure, good thermal stability, and little volatility, they have been researched as prospective refrigerants. Ionic liquids have the potential to be utilized in heat pumps, adsorption and absorption refrigeration systems. Ionic liquids are non-flammable, have low toxicity, and have a low impact on the environment when used as refrigerants. Additionally, because of their adjustable features, refrigerants may be created with the appropriate properties for certain applications. But in order to use ionic liquids as refrigerants more widely, issues including high cost, limited availability, and compatibility with current equipment must be resolved67–72.

Phase-Change Materials (PCMs)

Phase-change materials (PCMs) are substances that, when heated to a specified temperature, may change their phase (solid-liquid or liquid-gas) and store and release thermal energy. The use of PCMs for thermal energy storage in a variety of sectors, such as air conditioning and refrigeration, has been investigated. PCMs may be included in refrigeration and air conditioning systems to improve energy efficiency and lower peak load demand. PCMs can assist in controlling temperature variations and lowering the system's total energy consumption by storing and releasing thermal energy throughout the phase change process. The choice of suitable PCM for a refrigeration purpose relies on a number of variables, including the intended operating temperature range, heat transfer properties, and system compatibility. The goal of ongoing research is to create PCMs with enhanced thermal and durability characteristics to maximize their performance in refrigeration systems73–79.

Nano refrigerants

A relatively recent and promising advancement in the refrigeration industry is the use of Nano refrigerants. They are made up of nanoparticles that are scattered throughout conventional refrigerants. The thermal characteristics of the refrigerant, such as thermal conductivity and heat transfer coefficients, can be improved by the nanoparticles, which are frequently metallic or oxide-based. The performance and energy efficiency of refrigeration systems can be increased by adding nanoparticles to refrigerants. It is possible for nano refrigerants to increase heat transfer rates, lower refrigerant charges, and boost system dependability. Additionally, by enhancing system performance and lowering energy usage, they can help to reduce the overall impact on the environment. Although nano refrigerants have potential, further study is required to determine their long-term stability, safety issues, and environmental effect. The potential advantages of nano refrigerants must be carefully weighed against any potential hazards and difficulties in their actual application80–87.

Safety Considerations and Regulations

The selection and implementation of ecologically friendly choices heavily depend on the safety issues around refrigerants. This section examines the flammability and toxicity issues associated with refrigerants, as well as the safety requirements and installation guidelines, as well as the regulatory frameworks and phase-out timetables in place.

Risks of Flammability and Toxicity

For safe operation, refrigerants' potential for toxicity and flammability must be thoroughly assessed. While toxicity deals with a substance's potential negative effects on human health and the environment, flammability refers to a substance's capacity to ignite and maintain burning. When handling, storing, and installing flammable refrigerants, such as hydrocarbons (HCs) and some low-GWP HFC substitutes, extra safety measures must be taken. To reduce the dangers associated with flammable refrigerants, adequate equipment, leak detection systems, and proper ventilation are required. Another major factor is toxicity. In high quantities, some refrigerants, such as ammonia (NH3), can be poisonous. To guarantee worker and occupant safety, proper handling procedures, personal protection equipment, and adherence to suggested exposure limits are crucial. Implementing suitable safety measures and ensuring regulatory compliance need an understanding of the flammability and toxicity properties of refrigerants88–90.

Safety Codes and Standards

Refrigeration and air conditioning system design, installation, operation, and maintenance are all governed by safety standards and rules. Aspects including refrigerant choice, equipment design, leak detection, ventilation, and emergency response are covered by these standards and guidelines. Examples of widely accepted safety standards and codes include those created by groups like the International Electrotechnical Commission (IEC), the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), Indian Society of Heating, Refrigerating and Air Conditioning Engineers (ISHRAE), and the International Organisation for Standardisation (ISO). Specific criteria for refrigerant safety, system design, leak prevention, and emergency shutdown procedures are outlined in these standards and regulations. In order to minimise hazards to both human safety and the environment, refrigeration and air conditioning systems must be built and operated in accordance with safety regulations and rules91–94.

Regulatory Frameworks and Schedules for Phase-Out

At the national and international levels, regulatory frameworks and phase-out timelines are designed to control the use of ecologically hazardous refrigerants and encourage the switch to environmentally benign alternatives. The elimination of ozone-depleting compounds, such as CFCs and HCFCs, thanks to the Montreal Protocol, an international environmental accord, has significantly influenced the creation and uptake of more ecologically friendly substitutes. Many nations have developed rules and policies in addition to the Montreal Protocol to address the phase-out of high-GWP HFCs and promote the use of low-GWP substitutes. In order to encourage the switch to more environmentally friendly solutions, these rules place restrictions on the use, manufacturing, and importing of high-GWP refrigerants. To reduce the environmental effect and assure compliance, regulatory frameworks frequently contain measures for refrigerant management, leak detection, recovery, recycling, and safe disposal practices. To comply with legal requirements and promote environmental sustainability, it is crucial for players in the air conditioning and refrigeration business to be informed about the changing regulatory frameworks and phase-out timetables.

Challenges and Future Directions

Despite the advancements achieved in the creation of ecologically benign refrigerants, there are still many issues to be resolved. This section examines the future requirements for research and development as well as the technical difficulties and constraints, economic factors, and industry acceptance. The use of eco-friendly refrigerants might come with technological difficulties and restrictions. Certain refrigerants could differ thermodynamically from conventional ones, necessitating system modification and optimisation. For a smooth transfer, it is essential to take into account compatibility with current equipment, including compressors, seals, and lubricants. Alternative refrigerants may differ from conventional ones in terms of performance qualities, including dependability, capacity, and efficiency. A constant problem is achieving equivalent or better performance while still achieving environmental goals. Additionally, certain eco-friendly refrigerants, like natural refrigerants, have unique operating requirements, such high pressures or low temperatures, which may restrict their suitability for use in particular systems or regions. Researchers, engineers, and manufacturers will need to work together continuously to innovate and overcome these technological obstacles.

Economic factors drive the use of ecologically friendly refrigerants, but the expense of alternative refrigerants, equipment upgrades, and system retrofits can make it difficult for the industry to adopt them widely. To achieve economic viability, initial investment and long-term operational expenses must be thoroughly analysed, personnel and contractors may need additional training and certification, and accessibility and availability of alternative refrigerants and equipment can affect how widely they are used. Government incentives, legislation, and industry efforts may play a significant role in fostering the use of ecologically friendly refrigerants.

Research and development activities are necessary to advance the use of environmentally friendly refrigerants in the future. Areas that need more research include performance improvement, safety, materials compatibility, lifetime assessment, cost-cutting measures, and collaboration between academic, industrial, and governmental organisations. Performance improvement involves creating refrigerants with better thermodynamic properties, heat transfer characteristics, and system effectiveness. Safety involves conducting thorough evaluations of alternative refrigerants' flammability, toxicity, and long-term stability. Materials compatibility involves researching alternate refrigerants' compatibility with the materials used in refrigeration and air conditioning systems. Lifetime assessment involves carrying out thorough lifetime analyses of various refrigerants, encompassing manufacture, usage, and disposal phases. Cost-cutting measures involve investigating efficient production techniques and coming up with plans to bring down the price of equipment and refrigerants that are good for the environment.

Results

Based on the literature review, the results of the recent studies on environment friendly refrigerants are as follows:

Ammonia, carbon dioxide, hydrocarbons are natural refrigerants that possess a negligible ODP and exhibit significantly lower or zero GWP when compared to their synthetic refrigerants. These refrigerants are widely acknowledged as being highly environmentally benign, as they have the capacity to significantly mitigate greenhouse gas emissions within the air conditioning and refrigeration industry. Natural refrigerants are commonly employed as substitutes for synthetic refrigerants in a wide range of refrigeration and air conditioning applications.

Hydrofluoroolefins (HFOs) exhibit an ODP of zero and possess significantly lower GWP in comparison to hydrofluorocarbons (HFCs). They are being increasingly recognised as viable substitutes for hydrofluorocarbons (HFCs) in a range of refrigeration and air conditioning applications.

Mixtures or blends of HFO and HFC, environmentally friendly refrigerants enhance the performance of environmentally friendly refrigerants.

Ionic liquids, phase-change materials (PCMs), and nano refrigerants are examples of emerging technologies that have the potential to enhance the effectiveness and efficiency of refrigeration and air conditioning systems.

Safety factors must be taken into account when handling and employing environmentally friendly refrigerants, and compliance with safety standards and rules is essential.

Conclusion

In conclusion, the use of environmentally friendly refrigerants is crucial for sustainable and energy-efficient refrigeration and air conditioning systems. Based on this literature assessment, no refrigerant meets all technological and environmental criteria for sustainable refrigeration and air conditioning. Therefore, the selection of the best refrigerant depends on the specific application, system design, safety requirements, cost-effectiveness, and availability. The present literature review offers a complete examination of the existing research pertaining to environmentally sustainable refrigerants for the purposes of refrigeration and air conditioning. The comprehension of the merits and demerits of various refrigerants can aid researchers, manufacturers, policy makers, and consumers to make informed decisions on the best refrigerant for their specific application. Further investigation is required in order to formulate novel refrigerants that satisfy both technological and environmental prerequisites for the purpose of achieving sustainable refrigeration and air conditioning. Stakeholders may support a more environmentally friendly future while addressing the needs of cooling technologies by taking into account the environmental effect, safety, and energy efficiency of refrigerants.

Acknowledgement

The authors acknowledge the cooperation and support provided by the Campus Director/Principal, DSEU Pusa Campus (Pusa Institute of Technology) and Delhi Skill and Entrepreneur University.

Conflict of Interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Funding Sources

There is no funding or financial support for this research work.

References

- Arora CP. Refrigeration Air Conditioning, Nineteenth. Published online 2014.

- Sarbu I. A review on substitution strategy of non-ecological refrigerants from vapour compression-based refrigeration, air-conditioning and heat pump systems. International Journal of Refrigeration. 2014; 46:123-141.

- Abas N, Kalair AR, Khan N, Haider A, Saleem Z, Saleem MS. Natural and synthetic refrigerants, global warming: A review. Renewable and Sustainable Energy Reviews. 2018; 90:557-569.

- Bolaji BO, Huan Z. Ozone depletion and global warming: Case for the use of natural refrigerant–a review. Renewable and Sustainable Energy Reviews. 2013; 18:49-54.

- Fischer SK, McFarland M. Alternatives to CFCs and global warming: a systems approach to evaluating net contributions. MRS Bull. 1992;17(3):39-42.

- Babarinde TO, Akinlabi SA, Madyira DM. The Use of Hydrocarbon Refrigerants in Combating Ozone Depletion and Global Warming: A Review. Trends in Mechanical and Biomedical Design: Select Proceedings of ICMechD 2019. Published online 2021:731-739.

- Harby K. Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: An updated overview. Renewable and Sustainable Energy Reviews. 2017; 73:1247-1264.

- Lorentzen G, Pettersen J. A new, efficient and environmentally benign system for car air-conditioning. International journal of refrigeration. 1993;16(1):4-12.

- Barnes PW, Williamson CE, Lucas RM, et al. Ozone depletion, ultraviolet radiation, climate change and prospects for a sustainable future. Nat Sustain. 2019;2(7):569-579.

- Adeoye OJ, Aina SA. An appraisal of ozone layer depletion and its implication on the human environment. JL Pol’y & Globalization. 2019; 83:6.

- Boumaza M. Thermodynamic Performance Assessment of Ozone Layer Friendly Natural Refrigerants as Potential Substitutes to HCFC’s. International Journal of Chemical Engineering and Applications. 2015;6(1):18.

- Bolaji BO, Akintunde MA, Falade TO. Comparative analysis of performance of three ozone-friendly HFC refrigerants in a vapour compression refrigerator. Published online 2011.

- Benhadid-Dib S, Benzaoui A. Refrigerants and their environmental impact Substitution of hydro chlorofluorocarbon HCFC and HFC hydro fluorocarbon. Search for an adequate refrigerant. Energy Procedia. 2012; 18:807-816.

- Hirao T, MIZUNO H, UEDA K, KAI M, YAMADA H. Efforts to reduce greenhouse gas emissions for air conditioning and refrigeration products. Mitsubishi Heavy Industries Technical Review. 2018;55(1):38.

- Vuppaladadiyam AK, Antunes E, Vuppaladadiyam SSV, et al. Progress in the development and use of refrigerants and unintended environmental consequences. Science of the Total Environment. Published online 2022:153670.

- Venkatarathnam G, Murthy SS. Refrigerants for vapour compression refrigeration systems. Resonance. 2012;17(2):139-162. doi:10.1007/S12045-012-0015-X

- Heard BR, Miller SA. Critical research needed to examine the environmental impacts of expanded refrigeration on the food system. Environ Sci Technol. 2016;50(22):12060-12071. doi: 10.1021/ACS.EST.6B02740

- Benhadid-Dib S, Benzaoui A. Refrigerants and their environmental impact Substitution of hydro chlorofluorocarbon HCFC and HFC hydro fluorocarbon. Search for an adequate refrigerant. Energy Procedia. 2012; 18:807-816.

- Leighton D, Hwang Y, Radermacher R. Modeling of Household Refrigerator Performance with Low Global Warming Potential Alternative Refrigerants. ASHRAE Trans. 2012;118(1).

- Baskaran A, Mathews PK. A Performance comparison of vapour compression refrigeration system using Eco friendly refrigerants of low global warming potential. International journal of scientific and research publications. 2012;2(9):1-8.

- Souayeh B, Bhattacharyya S, Hdhiri N, Alam MW. Selection of Best Suitable Eco-Friendly Refrigerants for HVAC Sector and Renewable Energy Devices. Sustainability. 2022;14(18):11663.

- Bolaji BO. Selection of environment-friendly refrigerants and the current alternatives in vapour compression refrigeration systems. Published online 2011.

- McLinden MO, Seeton CJ, Pearson A. New refrigerants and system configurations for vapor-compression refrigeration. Science (1979). 2020;370(6518):791-796.

- Kilicarslan A, Müller N. A comparative study of water as a refrigerant with some current refrigerants. Int J Energy Res. 2005;29(11):947-959.

- Riffat SB, Afonso CF, Oliveira AC, Reay DA. Natural refrigerants for refrigeration and air-conditioning systems. Appl Therm Eng. 1997;17(1):33-42.

- Lorentzen G. The use of natural refrigerants: a complete solution to the CFC/HCFC predicament. International journal of refrigeration. 1995;18(3):190-197.

- Sruthi Emani M, Kumar Mandal B. The use of natural refrigerants in refrigeration and air conditioning systems: a review. In: IOP Conference Series: Materials Science and Engineering. Vol 377. IOP Publishing; 2018:012064.

- Yelishala SC, Ma X, Wang Z, Levendis YA, Metghalchi H. ASSESSMENT OF BLENDS OF HYDROCARBONS AND CO 2 AS ALTERNATIVE NATURAL REFRIGERANTS. In: ASTFE Digital Library. Begel House Inc.; 2018.

- Koh JH, Zakaria Z. Hydrocarbons as refrigerants? A review. ASEAN Journal on Science and Technology for Development. 2017;34(1):35-50.

- Granryd E. Hydrocarbons as refrigerants—an overview. International journal of refrigeration. 2001;24(1):15-24.

- Minor B, Spatz M. HFO-1234yf low GWP refrigerant update. Published online 2008.

- Hashimoto M, Otsuka T, Fukushima M, et al. Development of new low-GWP refrigerants–refrigerant mixtures including HFO-1123. Sci Technol Built Environ. 2019;25(6):776-783.

- Kim DH, Byun HW, Yoon SH, Song CH, Lee KH, Kim OJ. The latest review of low GWP (< 100) HFO refrigerants and studies on the pool boiling heat transfer. International Journal of Air-Conditioning and Refrigeration. 2016;24(04):1630009.

- Koban M. HFO-1234yf Low GWP Refrigerant LCCP Analysis. SAE International; 2009.

- Spatz M, Minor B. HFO-1234yf low GWP refrigerant: A global sustainable solution for mobile air conditioning. In: SAE Alternate Refrigerant Systems Symposium, Scottsdale, AZ, USA. ; 2008.

- Pham HM, Rajendran R. R32 and HFOs as low-GWP refrigerants for air conditioning. Published online 2012.

- Energy BB, 2010 undefined. Experimental study of R152a and R32 to replace R134a in a domestic refrigerator. Elsevier. Accessed May 29, 2023. https://www.sciencedirect.com/science/article/pii/S0360544210003014

- Bolaji BO, Akintunde MA, Falade TO. Comparative analysis of performance of three ozone-friendly HFC refrigerants in a vapour compression refrigerator. Published online 2011.

- Wu J, Chu Y, Hu J, Liu Z. Performance of mixture refrigerant R152a/R125/R32 in domestic air-conditioner. International journal of refrigeration. 2009;32(5):1049-1057.

- Pardo F, Gutiérrez-Hernández S V, Zarca G, Urtiaga A. Toward the Recycling of Low-GWP Hydrofluorocarbon/Hydrofluoroolefin Refrigerant Mixtures Using Composite Ionic Liquid–Polymer Membranes. ACS Sustain Chem Eng. 2021;9(20):7012-7021.

- McLinden MO, Brown JS, Brignoli R, Kazakov AF, Domanski PA. Limited options for low-global-warming-potential refrigerants. Nat Commun. 2017;8(1):14476.

- Tsai WT. Environmental risk assessment of hydrofluoroethers (HFEs). J Hazard Mater. 2005;119(1-3):69-78.

- Baptista VBC, Verissimo GL. Thermodynamic analysis of a residential air conditioning operating with ODP free and low GWP refrigerants. Revista de Engenharia Térmica. 2022;21(1):3-10.

- Bhutta MU, Khan ZA. Friction and wear performance analysis of hydrofluoroether-7000 refrigerant. Tribol Int. 2019;139:36-54.

- Abas N, Kalair AR, Khan N, Haider A, Saleem Z, Saleem MS. Natural and synthetic refrigerants, global warming: A review. Renewable and Sustainable Energy Reviews. 2018;90:557-569.

- Yin JM, Peng ZR, Zhang XR. Natural Refrigerants and Carbon Dioxide. In: CO2 Refrigeration Cycle and Systems. Springer; 2023:9-33.

- Hwang Y, Ohadi M, Radermacher R. Natural refrigerants. Mechanical Engineering. 1998;120(10):96-99.

- Anthony A A, Manohar K. Performance Assessment of Low Global Warming Potential Alternative Refrigerants. Journal of Energy Research and Reviews. 2023;13(3):26-40.

- Bošnjakovi? M, Santa R, Katini? M. Experimental Testing of a Water-to-Water Heat Pump with and without IHX by Using Refrigerants R1234yf and R1234ze (E). Sustainability. 2023;15(11):8625.

- Saengsikhiao P, Prapaipornlert C. Low GWP Refrigerant R1234yf, R1234ze (z), R13I1 as an Alternative to New Zeotropic Refrigerant. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences. 2022;98(2):80-89.

- Kumma N, Sarath S, Kruthiventi SSH. Exergy and performance analysis of low GWP and Non-flammable HFO based refrigerant mixtures as alternatives to R134a. Thermal Science and Engineering Progress. 2023;39:101691.

- Abdulla S, Ravikumar TS. Review on Pragmatic Refrigerants Deployed in Refrigeration and Air Conditioning System. In: Recent Advances in Manufacturing, Automation, Design and Energy Technologies: Proceedings from ICoFT 2020. Springer; 2022:795-801.

- Bolaji BO. Experimental study of R152a and R32 to replace R134a in a domestic refrigerator. Energy. 2010;35(9):3793-3798.

- Bellos E, Tzivanidis C. Investigation of the environmentally-friendly refrigerant R152a for air conditioning purposes. Applied Sciences. 2018;9(1):119.

- Mishra P, Soni S, Maheshwari G. Performance Evaluation of Split Air Conditioner with Consideration of Pressure Drop in Evaporator and Condenser. Current World Environment. 2022;17(3):592-601. doi:10.12944/CWE.17.3.8

- Tsai WT. Environmental risk assessment of hydrofluoroethers (HFEs). J Hazard Mater. 2005;119(1-3):69-78.

- Kví?ala J. Chemistry and applications of perfluoro-and polyfluoroethers. In: The Curious World of Fluorinated Molecules. Elsevier; 2021:319-342.

- Padmavathy SR, Chockalingam MP, Kamaraj N, Glivin G, Thangaraj V, Moorthy B. Performance studies of low GWP refrigerants as environmental alternatives for R134a in low-temperature applications. Environmental Science and Pollution Research. 2022;29(57):85945-85954.

- Mohanraj M, Abraham JDAP. Environment friendly refrigerant options for automobile air conditioners: a review. J Therm Anal Calorim. Published online 2020:1-26.

- Mohapatra A, Prusty AK, Nanda J, Das SN, Pandey H. Potential Refrigerants and Their Effect on the Environment—A Review. Current Advances in Mechanical Engineering: Select Proceedings of ICRAMERD 2020. Published online 2021:239-249.

- Kumma N, Seethala GS, Bhagat Y, Sarath S, Kruthiventi SSH. Theoretical performance studies on environment friendly refrigerants used in refrigeration units. Environmental Science and Pollution Research. 2023;30(22):63065-63083.

- Uddin K, Saha BB. An Overview of Environment-Friendly Refrigerants for Domestic Air Conditioning Applications. Energies (Basel). 2022;15(21):8082.

- Farooq M, Hamayoun A, Naqvi M, et al. Thermodynamic performance analysis of hydrofluoroolefins (HFO) refrigerants in commercial air-conditioning systems for sustainable environment. Processes. 2020;8(2):187.

- Nair V. HFO refrigerants: A review of present status and future prospects. International Journal of Refrigeration. 2021;122:156-170.

- Bhatti SS, Tyagi SK, Verma A. Energy and exergy analysis of vapour absorption cooling system driven by exhaust heat of ic engine. Lecture Notes in Mechanical Engineering. Published online 2021:269-276. doi:10.1007/978-981-15-6360-7_24/COVER

- It’s Cool To Be Sustainable: How Next-Gen Refrigerants Will Power The Economy And Protect The Environment. Accessed August 5, 2023. https://www.forbes.com/sites/honeywell/2021/06/22/its-cool-to-be-sustainable-how-next-gen-refrigerants-will-power-the-economy-and-protect-the-environment/?sh=4246250479ec

- Chugh D, Gluesenkamp K, Abdelaziz O, Moghaddam S. Ionic liquid-based hybrid absorption cycle for water heating, dehumidification, and cooling. Appl Energy. 2017;202:746-754.

- Park S, Choi HW, Lee JW, Cho HU, Lee NS, Kang YT. Performance analysis of ionic liquids for simultaneous cooling and heating absorption system. Energy. 2023;271:127005.

- Zheng D, Dong L, Huang W, Wu X, Nie N. A review of imidazolium ionic liquids research and development towards working pair of absorption cycle. Renewable and Sustainable Energy Reviews. 2014;37:47-68.

- Popp S, Bo?smann A, Wo?lfel R, Wasserscheid P. Screening of ionic liquid/H2O working pairs for application in low temperature driven sorption heat pump systems. ACS Sustain Chem Eng. 2015;3(4):750-757.

- Wu W, Leung M, Ding Z, Huang H, Bai Y, Deng L. Comparative analysis of conventional and low-GWP refrigerants with ionic liquid used for compression-assisted absorption cooling cycles. Appl Therm Eng. 2020;172:115145.

- Sui Y, Zhai C, Lin H, Wu W. How to rationally screen refrigerant/ionic liquids for thermal cooling: A multi-criteria approach based on machine learning. Energy Convers Manag. 2023;282:116853.

- Wang F, Maidment G, Missenden J, Tozer R. A review of research concerning the use of PCMs in air conditioning and refrigeration engineering. Advances in building technology. Published online 2002:1273-1280.

- Pop OG, Tutunaru LF, Bode F, Abrudan AC, Balan MC. Energy efficiency of PCM integrated in fresh air cooling systems in different climatic conditions. Appl Energy. 2018;212:976-996.

- Omara AAM, Abuelnour AAA. Improving the performance of air conditioning systems by using phase change materials: a review. Int J Energy Res. 2019;43(10):5175-5198.

- Moreno P, Solé C, Castell A, Cabeza LF. The use of phase change materials in domestic heat pump and air-conditioning systems for short term storage: A review. Renewable and Sustainable Energy Reviews. 2014;39:1-13.

- Ismail M, Zahra WK, Ookawara S, Hassan H. Enhancing the Air Conditioning Unit Performance via Energy Storage of Different Inorganic Phase Change Materials with Hybrid Nanoparticles. JOM. Published online 2023:1-15.

- Muzhanje AT, Hassan MA, Hassan H. Phase change material based thermal energy storage applications for air conditioning. Appl Therm Eng. Published online 2022:118832.

- Le TL, Duong XQ, Nguyen DT, et al. Application of phase change materials in improving the performance of refrigeration systems. Sustainable Energy Technologies and Assessments. 2023;56:103097.

- Aktemur C, Öztürk ?T. Thermodynamic performance enhancement of booster assisted ejector expansion refrigeration systems with R1270/CuO nano-refrigerant. Energy Convers Manag. 2022;253:115191.

- Xing M, Zhang H, Zhang C. An update review on performance enhancement of refrigeration systems using nano-fluids. Journal of Thermal Science. 2022;31(4):1236-1251.

- Tashtoush BM, Moh’d A AN, Khasawneh MA. Investigation of the use of nano-refrigerants to enhance the performance of an ejector refrigeration system. Appl Energy. 2017;206:1446-1463.

- Babarinde TO, Akinlabi SA, Madyira DM. Enhancing the performance of vapour compression refrigeration system using nano refrigerants: a review. In: IOP Conference Series: Materials Science and Engineering. Vol 413. IOP Publishing; 2018:012068.

- Vamshi J, Anand KM, Sharma A, et al. A review on the utilization of nanoparticles in the refrigeration system as nano-refrigerant and nano-lubricant. Mater Today Proc. 2022;50:782-788.

- Rahman S, Issa S, Said Z, Assad MEH, Zadeh R, Barani Y. Performance enhancement of a solar powered air conditioning system using passive techniques and SWCNT/R-407c nano refrigerant. Case Studies in Thermal Engineering. 2019;16:100565.

- Venkataiah S, Sthithapragna G. Comprehensive evaluation of nano refrigerants: A review. Mater Today Proc. 2023;72:937-942.

- Bibin BS, Amartya P, Govil K, Edison G. Performance of refrigeration system using Al2O3, CuO and TiO2 nano-enhanced refrigerants: A review. Mater Today Proc. Published online 2023.

- McLinden MO, Kazakov AF, Brown JS, Domanski PA. A thermodynamic analysis of refrigerants: Possibilities and tradeoffs for Low-GWP refrigerants. International Journal of Refrigeration. 2014;38:80-92.

- Vuppaladadiyam AK, Antunes E, Vuppaladadiyam SSV, et al. Progress in the development and use of refrigerants and unintended environmental consequences. Science of the Total Environment. Published online 2022:153670.

- Cai D, Hao Z, Xu H, He G. Research on flammability of R290/R134a, R600a/R134a and R600a/R290 refrigerant mixtures. International Journal of Refrigeration. 2022;137:53-61.

- ISHRAE: HVAC Society for Heating, Refrigerating, AC Engineers, Professionals & Students. Accessed June 6, 2023. https://ishrae.in/

- Home | ashrae.org. Accessed June 6, 2023. https://www.ashrae.org/

- Homepage | IEC. Accessed June 6, 2023. https://www.iec.ch/homepage

- Corberán JM, Segurado J, Colbourne D, Gonzálvez J. Review of standards for the use of hydrocarbon refrigerants in A/C, heat pump and refrigeration equipment. International Journal of refrigeration. 2008;31(4):748-756.