Reclamation of used lubricating oils

Vineet Katiyar1 * and Sattar Husain1

1

Department of Chemical Engineering,

A.M.U.,

Zakir Husain College of Engineering and Technology,

Aligarh,

202 002

India

DOI: http://dx.doi.org/10.12944/CWE.5.1.11

Lubricating oils are widely used to reduce friction and wear by interposing a film of material between rubbing surfaces. However, the used lubricant oil does not evaporate and less subject to biodegradation. It requires proper treatment before it can be discharged to the environment. Recently, there is an increase tendency of using used lubricating oil as re-refining feedstock on a worldwide basis. Re-refining of used lubricating oil is an intelligent option for any country, more so for India, as it would conserve both the natural resources as well as foreign exchange. It would also make us near self-reliant in lube oils.

Copy the following to cite this article:

Katiyar V, Husain S. Reclamation of used lubricating oils. Curr World Environ 2010;5(1):79-84 DOI:http://dx.doi.org/10.12944/CWE.5.1.11

Copy the following to cite this URL:

Katiyar V, Husain S. Reclamation of used lubricating oils. Curr World Environ 2010;5(1):79-84. Available from: http://www.cwejournal.org/?p=1106

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2010-04-25 |

|---|---|

| Accepted: | 2010-05-18 |

Introduction

A huge amount of used lubricating oils are produced worldwide. The different sources of used lubricating oils are railway workshops, industries, ship garages, defense machinery, automobiles workshops, etc. All types of lubricating oils in service in automobiles and process industries become contaminated and lose their performance due to changes in some of their properties. Therefore, such oils must be removed as used oil from the service as frequently as necessary. How to handle and what to do with the used lubricating oils are serious concerns to environmentalists, governments, industries and research scientists. Used lubricating oil disposal techniques of the past such as land filling, road oiling, and track side foliage control, indiscriminate dumping, burning for energy, etc., create serious environmental problems. Many of these disposal techniques are severely restricted by current state and federal environmental regulations.1 The common disposal technique of used lubricating oil is burning for generation of energy. Burning and all other routes of disposals of used lubricating oils are uneconomical and result in the wastage of resources.2-6 The recycling of waste lubricating oils may be a suitable and economical alternative to burning and incineration.7 Different techniques have been developed for reclaiming and re-refining waste lubricants oils to either restore the original usefulness of the oil or clean the contaminated oils to a point that they can become suitable for sub-sequent use. Among these methods, reclaiming by heating and filtration, re-refining by introducing waste oil into crude oil refining streams, recycling by acid/clay treatment, thin film evaporation/clay contact finishing, thin film evaporation/hydro treats finishing, etc, are now employed in different countries worldwide.8-12 Environmental concerns are associated with all those methods except the last which is usually the most expensive and needs a re-refining installation. Thin film evaporation methods are generally used in North America and Europe while the other methods, particularly the acid/clay technique are employed usually in the developing countries. This process has been employed for many years as the premier type of re-refining in which concentrated sulfuric acid is introduced to dehydrate waste lubricant oil. An acidic sludge is produced which is treated with clay. The acidic sludge and oily clay disposal is a matter of greater environmental concern. Changing away from the notorious acid/ clay process to some form of distillation has been made in the past.13-14

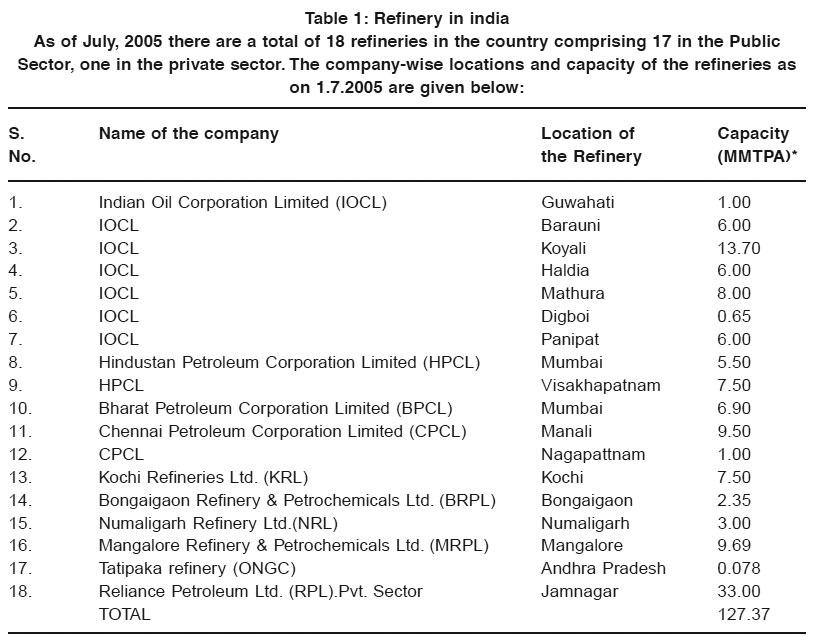

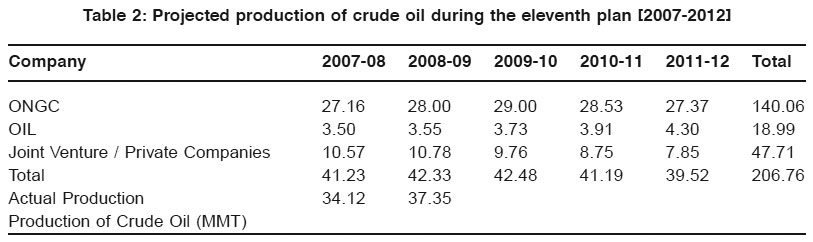

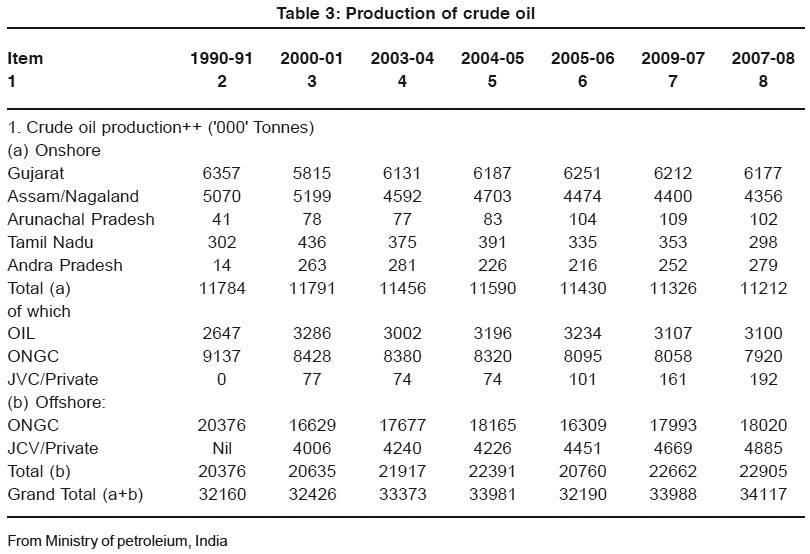

The most important route to conserve lubricants is that of recycling. Recycling is a generic term for processing used lube oil to regain useful material through reclamation and re-refining. The important statistical data relating to the oil sector is given in Tables 1, 2 and 3.

|

Table 1: Refinery in india As of July, 2005 there are a total of 18 refineries in the country comprising 17 in the Public Sector, one in the private sector. The company-wise locations and capacity of the refineries as on 1.7.2005 are given below: Click here to view table |

Several Re-Rrefining Technologies

There are several re-refining technologies.

These are:

- Acid clay process

- Prop process

- Sulfuric Acid Refining

- Propane Extraction Process

- Mohawk Technology

- KTI process

- Safety Kleen Process

- DEA Technology

- High-temp Clay Reclamation

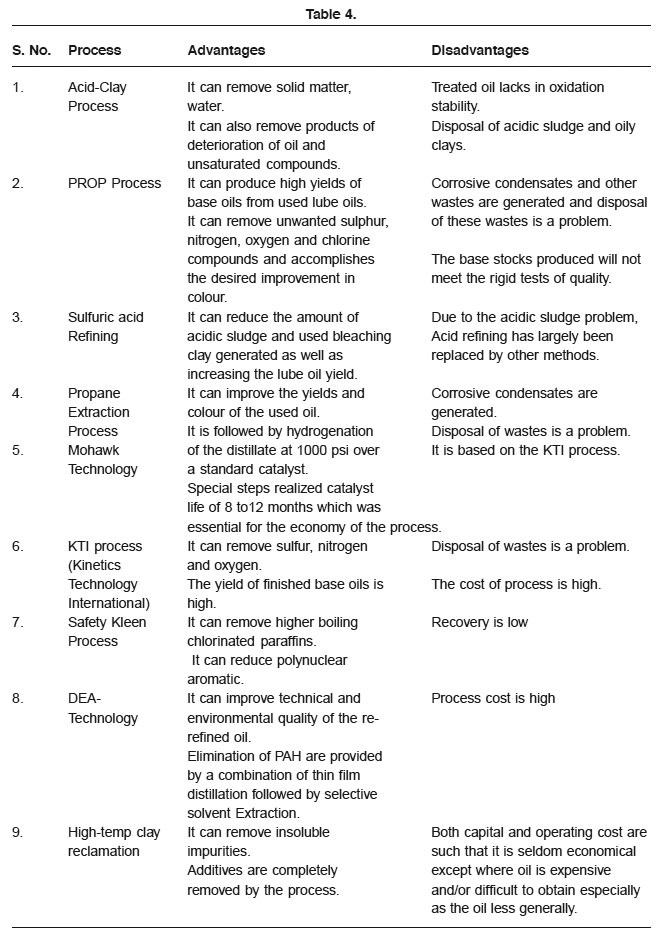

The advantages and disadvantages of these processes are summarized in Table - 4.14-17

|

Table 2: Projected production of crude oil during the eleventh plan [2007-2012] Click here to view table |

Burning Used Oil an Environmental Issue

When any substance is burned, the elements and compounds of which it is made up are released into the air as gases or particles, or they collect in the ash. If released in high enough quantities, some of these gases and particles can have harmful effects on human health and the environment. The ash can also be harmful. The effects on human health can be direct or indirect. Direct harm to human health can occur when the fine particles are inhaled into the lungs. People with asthma or existing respiratory disease are most likely to suffer direct adverse health effects. Indirect effects occur when the fine particles, which contain contaminants such as heavy metals, settle on food crops and end up in the food we eat. Some oil can be burned without causing adverse effects on human health and the environment. To achieve this usually requires strict conditions such as:

- Controlling the content of the substance burned

- Using filters and scrubbers to remove particles and chemicals from the discharge

- Designing chimney stacks to ensure good dispersion of the discharge

- Ensuring the burner operates to a particular degree of combustion efficiency (temperature, residence time, etc)

- Specifying methods of containing and disposing of ash.

|

Table 3: Production of crude oil Click here to view table |

Unused oil

The materials listed below are not used oil.

- Used animal or vegetable oils (they are considered food wastes rather than used oil, because they are not synthetic and not derived from crude oil).

- Unused contaminated or uncontaminated oils going for reclamation.

- Solid wastes contaminated with used oil (such as absorbents and scrap metal) that are not burned for energy recovery and that do not have free-flowing oil.

- Solvents (such as petroleum spirits, mineral spirits, petroleum ether, acetone, fuel additives, alcohols, paint thinners, brush cleaners, and other cleaners)

- Substances that cannot readily be recycled in the same processes as used oil.

- Used antifreeze.

Uused oil

Used oil includes of the materials listed below.

- Any oil, either synthetic or refined from crude oil, that has been used for its designed and intended purposes; and as a result of use, is contaminated by physical or chemical impurities; and as a result, has become a spent material (that is, it can no longer be used for its originally intended purpose without processing).

- Used oil to be burned for energy recovery.

- Any other material that has physical and chemical properties similar to used oil, is used in normally accepted functions of oil.

- Used oil that is characteristically hazardous from use (as opposed to oil rendered characteristically hazardous by mixing).

|

Table 4 Click here to view table |

Examples of Used Oil

The following lists give some examples of oils that have become spent materials through use.

Spent Engine Oil and Vehicle Lubricants

Used oils include, but are not limited to, the following spent engine lubricating oils and vehicle fluids:

- Automotive crankcase oil, including car, truck, marine, and aircraft engine oils not used for engine fuel;

- Diesel engine crankcase oil, including car, truck, bus, marine, heavy equipment, and railroad engine oils not used for fuel;

- Natural-gas-fired engine oils;

- Alternative fuel engine oils;

- Transmission fluids;

- Brake fluids; and

- Power steering fluids.

Spent Industrial Oils

Used oils also include, but are not limited to, the following spent industrial oils:

- Compressor, turbine, and bearing oils;

- Hydraulic oils or fluids;

- Metalworking oils or oil emulsions, including cutting, grinding, machining, rolling, stamping, quenching, and coating oils; electrical insulating oils;

- Refrigerator/air conditioning unit oils;

- Rubber-making oils;

- Cable oils;

- Greases; and

- Oil-like heat transfer fluids.18-19

Conclusion

Used oil is a pollutant and by re-refining, the pollution is reduced. The quality of thoroughly re-refined oil is comparable with nascent base oils. Hence, it should be awarded import-substitute status. While making fresh lubricating oils, blending with 5 -10% of re-refined base oils should be done for viscosity correction. All such blended oils should be stamped with eco-label/green label to make the public aware about the concept of re-refining. The eco-conscious customers would buy the product with green label. Since re-refining leads to oil conservation; the concept of re-refining should be strongly supported by the Petroleum Conservation Research Association.

References

1. Pyziak, T.; Brinkman, D. W. Lub. Eng. (1993) 49: 339-346.

2. Wu, Y.S.; Yang, M.-H.; Lin, C.-E. A. J. Chin. Chem. Soc., (1985) 32(1): 53.

3. Li, N. C.; Tzou, Ji R.; Chang, H.;Wang, S. M. J. Chin. Chem. Soc., (1987) 34(2): 91.

4. Huang, C.-T.; Hsieh, Y.-Z. J. Chin. Chem. Soc., (2002) 49(4): 517.

5. Ishaq, M.; Iqbal, Y.; Ahmad, I.; Waqar, K. J. Chin. Chem. Soc, (2002) 49(1): 57.

6. Wang, S. M.; Li, N. C.; Chang, H. et al. J. Chin. Chem. Soc., (1989) 36(4): 357.

7. Bhaskar, T.; Uddin, Md. A.; Sakata, Y. Fuel, (2004) 83: 9.

8. Lazaro, M.; Moliner, R.; Suelnes, I. Energy Fuels, (1999) 13: 907.

9. Wrinkman, D.W.; Dikson, J. R.;Wilkinson, D. Environ. Sci.Technol., (1995) 29: 87.

10. Brinkman, D. W. Lub. Eng., (1987) 43: 324.

11. Keagan, D. J. Mc. Lub. Eng., (1992) 48: 420.

12. Brinkman, D.W.; Dickson, J. R.Environ Sci. Technol., (1995) 29: 81-86.

13. Whisman, M. L. Lub. Eng., 35: 249 (1979).

14. Lafrenz, C. Technology of regeneration. Proc. of 2nd Europ.Cong. On Recycling of used oils; Paris (1980).

15. J.W. Goetzinger, oil and gas journal, (1975) 73(9): 130-135.

16. A. Prasad, Small Business publication, 58-60 [1977]

17. S. Forsberg, Lubrizol corp. 56(9): (1977) 18-20.

18. www.tceq.state.tx.us/rules

19. Used Oil Recovery, Reuse and Disposal in New Zealand, the Environment’s web site at www.mfe.govt.nz