Characterization of Processed Jatropha Oil for use as Engine Fuel

Anil Kumar Dubey1 * , R.M. Sarviya2 and A. Rehman2

1

Division of Agricultural Energy and Power,

Central Institute of Agricultural Engineering,

Bhopal,

462 038

India

2

Department of Mechanical Engineering,

Maulana Azad National Institute of Technology,

Bhopal,

462 051

India

DOI: http://dx.doi.org/10.12944/CWE.6.1.14

Out of various no edible oil resources, jatropha curcas oil is considered as a promising alternate fuel for CI engines. The present study describes the process used for production of degummed jatropha oil (DGJO) and jatropha methyl ester (JBD) The important fuel properties of DGJO and JBD were determined and compared with fossil diesel and jatropha oil. The degumming and trans esterification process has reduced the viscosity by 19.8% and 74.8% respectively. The heating of degummed oil at 70 0C reduce the viscosity by 6.8 times when compared with viscosity at 10 0C. Further the degummed oil at 70 0C becomes viscous at par with fossil diesel, hence could be used directly in IC engines.

Copy the following to cite this article:

Dubey A.K, Sarviya R.M, Rehman A. Characterization of Processed Jatropha Oil for use as Engine Fuel. Curr World Environ 2011:6(1);101-107 DOI:http://dx.doi.org/10.12944/CWE.6.1.14

Copy the following to cite this URL:

Dubey A.K, Sarviya R.M, Rehman A. Characterization of Processed Jatropha Oil for use as Engine Fuel. Curr World Environ 2011;6;101-107. Available from: http://www.cwejournal.org/?p=1289

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2011-03-29 |

|---|---|

| Accepted: | 2011-05-04 |

Introduction

The increasing concern on environmental protection and the stringent exhaust gas regulation has made the attention on use of vegetable oil as alternate fuel for engines. The use of vegetable oil in compression ignition engine is as old as diesel engine itself. In Rudolph Diesel’s preface to his 1912 patent he wrote that the “Use of vegetable oil for engine fuel may seem insignificant today but such oil may became in coarse of time, as important as petroleum” (Vasudevan, 2005). Vegetable oils have the greatest promise to be used as alternate fuels for diesel engines due to a very significant fact that they are renewable energy sources and could emit substantially less green house gases (Pugazhvadivu, 2005). The cetane number and calorific values of vegetable oil are close to petro diesel hence could be directly used in compression ignition engines. The Vegetable oils develop the same power output with lower thermal efficiency when used in diesel engine (Srivastava & Prasad, 2000). The problems observed with the use of vegetable oils as fuel in diesel engine are poor fuel atomization and low volatility due to their high viscosity, high molecular weight and density. The Jatropha oil being non edible and most promising source of oil for use as fuel in IC engines was selected for its characterization. In the present investigation, the Jatropha oil was processed i) to remove gums and phophatide present in the raw oil by hot water degumming method and ii) to convert the jatropha oil in to jatropha methyl ester(bio diesel) by trans esterification process using methanol and base catalyst. The raw Jatropha oil (JO), degummed Jatropha oil (DGJO) and Jatropha bio diesel (JBD) were characterized for fuel properties and thermal behaviour i.e. volatility at different temperature to assess the suitability of oil as fuel for CI engines.

Jatropha Carcus

Jatropha carcus is a large shrub commonly found throught most of tropical and subtropical regions of the world. It is a draught resistant perennial plant living up to 50 years and has capability to grow on marginal soils. It requires very little irrigation and grows in all types of soil ( Banapurmath, 2008). The Government, NGO and farmers have shown interest in cultivation of crops in waste land to cater the energy needs of the rural sector. The yield of plant could be 2-3 tonnes per hectare. The average oil content of dry seed was 34.4%. The energy content of karnel, shell and oil were 30.4MJ/kg, 19.4MJ/kg and 39.63MJ/kg respectively (Achten, 2008). The plantation of Jatropha could provide solution to energy and employment in rural areas and finally improve the quality of rural life.

Processing of Jatropha Oil

The process used to make the JO suitable for use as engine fuel are i) Degumming process and ii) Trans esterification process.

|

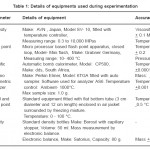

Table 1: Details of Equipments Used During Experimentation Click here to View table |

Degumming Process

The degumming of oil was done by adopting hot water treatment process. The filtered oil was heated up to 70 0C in water bath. The hot water(3% of oil volume basis) was added in hot oil and stirred to get reacted with phosphetides. The reaction was carried out at 70oC for 40 minutes duration. The reacted oil was cooled to ambient temperature and centrifuged at 5000rpm at 10 0C for 30 minute duration to separate the gums and phosphetides from oil. The oil was further dried in oven to remove the traces of water at low temperature at 80 0C. The dried degummed oil is used for its characterization.

Transesterification Process

The JO was transesterified to produce jatropha methyl ester further referred JBD. The process flow chart used for transesterification process is shown in figure1. The material used in transesterification process were 1.2 percent Sodium hydroxide (NaOH) of JO and methanol was in 6:1 molar ratio with JO.

The Jatropha oil was heated up to 65 0C. The solution of methanol with NaOH was prepared and added in hot oil (650C). The mixture of oil and methanol was agitated with stirrer at 25rpm at 65+/ - 1 0C for one hour duration. The reacted oil was kept in settling tank for two hours to separate the glycerol from bio diesel. After two hours of settling time the glycerol was separated from bio diesel. The bio diesel was washed twice in equal amount of water and dried at low temperature. The bio diesel thus produced was used for characterization.

|

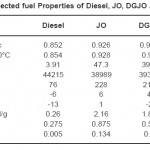

Table 2: Selected Fuel Properties of Diesel, JO, DGJO and JBD Click here to View table |

Oil Characterization

The raw and processed (degummed and trans-esterified) Jatropha oil was used for their characterization. The sufficient quantity of degummed oil and biodiesel were prepared for the study. The fuel parameters characterized were mainly the viscosity, calorific value, flash point, density and thermal decomposition for analysis as fuel for compression engines. The viscosity of oil, which is considered one of the important parameter was determined at different temperature and compared with diesel collected from Indian oil corporation outlet. The equipments used for measurement of various parameters are given in Table-1.

Results and Discussion

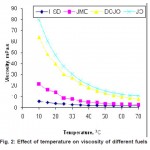

Kinematic Viscosity

The viscosity measured at 10-70 0C for raw jatropha oil(JO), degummed Jatropha oil(DGJO) and jatropha bio diesel(JBD) are presented in Figure 3. As the temperature increase the viscosity of oil reduces and reaches close to diesel fuel. The viscosity of JO reduces by 7.4 times when temperature raised from 10-70 0C. Similarly the viscosity reduction for DGJO and JBD was 8.3 and 7.3 times with increase in temperature from 100C - 70 0C. The pre heating of oil has shown significant effect on reduction in viscosity. The viscosity of JBD was 2.9 cst at 70 0C. The processing of Jatropha oil by degumming and trans-esterification process has shown reduction in viscosity. The reduction in viscosity by degumming and trans-esterification process of JO was 19.8 and 74.8 percent respectively. The viscosity of JO and DGJO was 10.8 cst and 8.4 cst at 70°C respectively where as the ISI limit for Grade B diesel fuel was 2.5 to 15 cst. This indicates that the preheating of JO and DGJO at 70 0C confirms the viscosity of B grade diesel. The results obtained are in line with reported by Parmarik(2003), Gubitz(1999), and Demirbas (2009).

|

Figure 1: Process chart for bio diesel Production Click here to View figure |

|

Figure 2: Effect of Temperature on Viscosity of Different Fuels Click here to View figure |

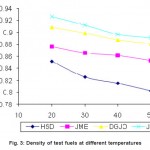

Density and Specific Gravity

The density of diesel fuel, jatropha oil, degummed jatropha oil, and jatropha oil methyl ester were found to be 0.852, 0.926, 0.909 and 0.875 g/cc respectively at 20ºc temperature. The variation in densities at different temperature for JO, DGJO, JBD and HSD are shown in figure 4 The results indicated that temperature have significant effect on the density of the test fuels. The densities and specific gravities of the test fuels decreased with increase in temperature. This is in agreement with the finding of many researchers including Shyam et al.,(1987), Ali et al (1995), Gupta etal (1997) and Verma etal (1998). The density of JO, DGJO and JBD were observed to be 8.7, 6.6 and 2.7 percent higher than the diesel fuel. A similar trend was reported by many researchers including Goering et al (1982), Gupta etal (1997), Ali et al (1995). The higher density and specific gravity of the vegetable oil than that of diesel may be attributed for the higher molecular weight of triglyceride molecules.

|

Figure 3: Density of Test Fuels at Different Temperatures Click here to View figure |

|

Figure 4(a): Thermo grams of test fuels Figure 4(b): The derivatives of test fuels Click here to View figure |

Gross Heating Value

The gross calorific value of high speed diesel Jatropha oil, degummed Jatropha oil and Methyl ester of Jatropha oil are presented in the table5. The calorific of JO, DGJO and JBD were 11.81%, 10.98% and 9.7% lower that of HSD respectively. Heating value of fuel determines the heat availability to produce the power. Therefore, higher gross heating values weighed in favour of the choice of an alternate fuel for engine because of lower specific fuel consumption. These results are in general agreement with Georing et al., (1982), Altin et al (2001) and Ali & Hana (1995).

Cloud Point and Pour Point

The cloud point and pour point indicate the cold flow behaviour of a fuel which are poor for JO and DGJO when compared with diesel fuel. The cold point and pour point temperature was 12 0C and 140C for JO and 10 and 11 0C high for DGJO. The results are in line with the finding of Bhatt (1997), Sarin et al.,(2009) and Gupta et al., (2002).

|

Table 5: Distillation properties of JO, DGJO and JBD and fossil diesel fuel Click here to View table |

Flash Point

The flash point of High speed diesel, degummed jatropha oil & jatropha oil are presented in the table 2. The result of flash point of JO, DGJO and JBD was high 1520C, 1400C and 920C as compared to diesel fuel. The result of flash point test was in agreement with the values reported by Georing et al.,(1982) and Gubitz et al., (1999). The flash point is important from the point of view of safe handling and storage of the fuel. Thus, the handling and storage of JBD, DGJO and JO are relatively less hazardous as compared to diesel fuel.

Thermo Gravimetric Analysis of Test Fuel

The thermal analysis of high speed diesel, Jatropha biodiesel, degummed Jatropha oil and Jatropha oil was done in Nitrogen atmosphere with 10°C per minute temperature rise. The graphical presentation of percent weight loss with change in temperature (thermo gram) were presented in Fig 5a. The boiling temperature of test fuel and distillation properties were determined based on thermogram and reported in the table 3. The boiling temperature of JBD, DGJO and JO were 89°C, 218°C, and 219°C higher than the diesel fuel. The test results are in line with Goodrum (2002), and Lang et al (2001). The derivatives of test fuel are shown in figure 5b. The maximum rate of weight loss was observed at 8.0g/min at 250°C for HSD 13.0g/min at 310°C for JBD, 22.5 g/min at 410°C for DGJO and 23.5g/min at 415°C for JO were observed.

Figure 5.8 Derivatives of Jatropha oil, degummed jatropha oil, biodiesel of Jatropha oil and diesel fuel.

The thermo gram indicates that decomposition of JO, DGJO and JBD. Degummed oil and bio diesel fuel starts at 360 0C, 300 0C, 200 0C as compared to diesel fuel of 130 0C. The decomposition completes at 490 0C, for oil, 480 0C for degummed oil and 310 0C is for bio diesel and 305 0C is for diesel fuel. The rate of decomposition was 8.0 g/min at 250 0C whereas the bio diesel was 13.0 g/min at 310 0C for bio diesel, 22.5 g/min at 410 0C for degummed oil and 23.5 g/min at 4150C for raw oil.

Conclusion

- The reduction in viscosity by degumming and trans-esterification process of JO was 19.8 and 74.8 percent respectively. The heating of Jatropha oil from 10 0C to 70 0C has reduced the viscosity by 7.4 times.

- The density of JO, DGJO and JBD were observed to be 8.7, 6.6 and 2.7 percent higher than the diesel fuel.

- The flash point of JO, DGJO and JBD were high by 1520C, 1400C and 920C as compared to diesel fuel.

- The calorific of JO, DGJO and JBD were 11.8%, 11.0% and 9.7% lower lower than the calorific value of diesel fuel.

- The thermo gram has shown that the DGJO would have less carbon residue as compare to JO. The degummed oil has no significant effect on volatization properties as compare to JO, where as JBD has similar volatization characteristics of diesel fuel.

References

- Ali, Y., Hana, M.A. and Borg, JE., Optimization of diesel, methyl tallowate and ethanol blend for reducing emissions from diesel engine. Bioresource Technology 52: 237-243 (1995).

- Achten WMJ, Verchot L, Franken YJ, Mathijs E, singh VP,Aerts R and Muys B; Jatropha biodiesel production and use, Biomass and Bio Energy, 32: 1063-1084 (2008).

- Altin Recep, Cetinkaya C and Yucesu HS; The potential of using vegetable oilfuels as fuel for diesel engines; Energy conversion and Management,42: 529-538 (2001).

- Banapurmath NR,Tewari PG and Hoshmath RS., Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters; Renwable Energy, 33: 1982-1988 (2008).

- Bhatt, Y.C., Use of some non edible oils as a source of energy for CI engines. Unpublished Ph.D. Thesis, IIT Kharagpur India 285 (1987).

- Demirbas, Ayhan, Progress & recent trends in biodiesel fuel, Energy Conversion & Management 50: 14-34 (2009).

- Georing, C.E., Schwab, A.W., Daugherty, M.J., Pryde, E.H. and Heazkin, A.J., Fuel properties of eleven vegetable oils. Transaction. ASAE: 1472-1477 (1982).

- Gupta, P.K., Verma, S.R., Sangha, M.K., Thapar, V.K., Bal, A.S. and Dixit, Annop.,Characterization of selected plant oils and their methyl ester.Paper presented in XXXII annual convention of ISAE held at PAU, Ludhiana during April 16-18, 1997 (1997).

- Gupta, P.K., Panesar, B.S., Kumar, R. and Anupma. Studies and use of selected biodiesel as alternate fuels for compression ignition engines: Brief progress report of ICAR Adhoc Research Project. PAU, Ludhiana (2002).

- Goodrum JW;Volatility and boiling points of biodiesel from vegetable oils and tallow; Biomass and Bioenergy, 22: 205-211 (2002).

- Gubitz, G. M., Helbach, M. M. and Trabi M., Exploitation of the tropical oil seed plant Jatropha Curcus L., Bioresource Technology 67: 73-82 (1999)

- Lang X, Dalai AK, Bakhshi NN, Reaney MJ and Hertz PB; Preparation and characterization of bio diesel from various bio oils; Bio Resource Technology, 80: 53-62 (2001).

- Pramanik, K., Properties and use of jatropha curcus oil and diesel fuel blends in compression ignition engine, Renewable Energy 28: 239- 248 (2003).

- Pugazhvadivu M. and Jeyachandran K.; Investigations on the performance and exhaust emissions of a diesel engine using preheated waste frying oil as fuel; Renewable Energy 30: 2189–2202 (2005).

- Sarin Amit, Rajnish Arora, Singh, N.P., Sarin Rakesh, Malhotra, R.K. and Kundu, K., Effect of blends of Palm, Jatropha, Pongamia biodiesel on cloud point. Energy 34: 2016-2021 (2009).

- Shyam, M., Verma, S.R. and Pathak, B.S., Physico-Chemical properties of plant oils and blends in diesel and kerosine oils, Energy, 12(7): 589-598 (1987)

- Srivastava A, Prasad R, Triglyceride based fuels, Rene Renew Sustain Energy Rev., 4: 111-133 (2000).

- Vasudevan P, Sharma S and Kumar A.2005, Liquid fuel from biomass: an overview. Journal of Science Indian Resarch,64(11),822–31.

- Verma, S.R., Gupta, P.K., Thaper, V.K. and Bal, A.S., Studies on bulk production and use of selected plant oil esters as alternate renewable fuel for diesel engines. Final report on ICAR Adhoc scheme, Dept. of F.P.& M., PAU, Ludiana (1998).