Effects of Biodiesel and Engine Load on Some Emission Characteristics of a Direct Injection Diesel Engine

Alireza Shirneshan1 * , Morteza Almassi2 , Barat Ghobadian3 , Ali Mohammad Borghei1 and Gholamhassan Hassan Najafi3

1

Department of Agricultural Machinery Engineering,

Science and Research Branch,

Islamic Azad University,

Tehran,

Iran

2

Department of Agricultural Mechanization,

Science and Research Branch,

Islamic Azad University,

Tehran,

Iran

3

Department of Mechanics of Agricultural Machinery,

Tarbiat Modares University,

Tehran,

Iran

DOI: http://dx.doi.org/10.12944/CWE.7.2.03

Copy the following to cite this article:

Shirneshan A, Almassi M, Ghobadian B, Borghei A.M, Najafi G.H. Effects of Biodiesel and Engine Load on Some Emission Characteristics of a Direct Injection Diesel Engine. Curr World Environ 2012;7(2):207-212 DOI:http://dx.doi.org/10.12944/CWE.7.2.03

Copy the following to cite this URL:

Shirneshan A, Almassi M, Ghobadian B, Borghei A.M, Najafi G.H. Effects of Biodiesel and Engine Load on Some Emission Characteristics of a Direct Injection Diesel Engine. Curr World Environ 2012;7(2):207-212. Available from: http://www.cwejournal.org/?p=275

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2012-07-12 |

|---|---|

| Accepted: | 2012-09-17 |

In recent years, the demands for energy have grown very quickly due to the rapid development of certain growing economies, especially in Asia and the Middle East. Biofuels such as alcohols and biodiesel have been proposed as alternatives for diesel engines.1,2,3 Especially, the environmental issues concerned with the exhaust gases emission by the usage of fossil fuels also encourage the usage of biodiesel, which has proved to be ecofriendly far more than fossil fuels. In particular, biodiesel has received wide attention as a replacement for diesel fuel because it is biodegradable, nontoxic and can significantly reduce toxic emissions and overall life cycle emission of CO2 from the engine when burned as a fuel.4,5

Biodiesel is known as a carbon neutral fuel because the carbon present in the exhaust was originally fixed from the atmosphere.6 This supply deficit will have serious implications for many non-oil producing countries which are dependent on oil imports. Furthermore, the extensive use of fossil fuels has increased the production of greenhouse gases, especially carbon dioxide (CO2), thus exacerbating the greenhouse effect. The potential to both reduce fossil fuel reliance and the release of CO2 to the atmosphere.

Biodiesel from waste cooking oil is a more economical source of the fuel. Kulkarni and Dalai7 concluded that the engine performance of biodiesel obtained from waste frying oil is better than that of diesel fuel while the emissions produced by the use of biodiesel are less than those using diesel fuels except that there is an increase in NOx.

Lapuerta et al.,8 tested two different biodiesel fuels obtained from waste cooking oils with different previous uses on diesel particulate emissions. They found no important differences in emissions between the two tested biodiesel fuels.

Based on exhaustive engine tests, it can be concluded that bio-diesel can be adopted as an alternative fuel for existing conventional diesel engines without requiring any major modifications in the mechanical system of the engines. Bio-diesel emissions in a conventional diesel engine contain substantially less unburned HC, CO, sulfates, polycyclic aromatic hydrocarbons, nitrated polycyclic aromatic hydrocarbons and PM than conventional diesel emissions.9,10 The NOx emissions from bio-diesel blends of various origins are slightly lower than those of conventional diesel, and the difference is greater for blends with higher percentages of bio-diesel.11 Other researchers have observed the same behavior for all vegetable oil blends of various origins.12,13,14 Various studies have shown that biodiesel made from waste cooking oil can be used in different types of diesel engines with no loss of efficiency15 and significant reductions in PM emissions,16,17,18,19,20 Co emissions17,20 and total hydrocarbon (THC) emissions19,21 when compared with emissions from conventional fossil diesel fuel. The performance and smoke results obtained from an engine used for generating electricity, when fueled with biodiesels of waste cooking oil origin, showed that the smoke reduction was about 60% for B100 and approximately 25% for B20.12 Dorado et al.,22 used waste olive oil in a four-stroke, three-cylinder, and 2.5 L direct injection engine with a power rating of 34 kW through an eight mode test. They achieved 58.9% reduction in CO, 8.6% reduction in CO2 and 57.7% reduction in SO2 emissions. On the other hand, increases of 32 and 8.5% in the NOx emissions and specific fuel consumption were observed in the B100 and B20 mixtures, respectively. Murillo et al. (2007)23 tested a four-stroke diesel outboard engine running on conventional diesel, conventional diesel blended with certain amounts of waste cooking oil biodiesel (10, 30 and 50%), and pure bio-diesel and proved that the bio-diesel blends are environmentally friendly alternatives to conventional diesel. They found some reduction in power of approximately 5% with B10 and B30, and 8% with B50 and B100 with respect to the power obtained from conventional diesel.

The biodiesel from waste cooking oil was tested by Meng et al.,24 on an unmodified diesel engine, and the results showed that under all conditions, the dynamical performance remained normal. Moreover, B20 and B50 blend fuels created unsatisfactory emissions, while the B20 blend fuel reduced PM, HC and CO emissions significantly. In another study, wasted cooking oil from restaurants was used to produce neat biodiesel through transesterification, and this converted biodiesel was then used to prepare biodiesel/diesel blends. The authors of the study concluded that B20 and B50 are the optimum fuel blends in terms of emissions.25

In this research, the performance of waste frying oil methyl ester blended with diesel fuel in ratios of 20% (B20), 40% (B40), 60% (B60) and 80% (B80) was investigated and compared with that of regular diesel in terms of emissions in diesel engine under four engine loads at an engine speed of 1800 rev/min.

Material and Methods

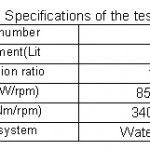

The experiments were conducted on a four cylinders, four-stroke, turbocharged direct injection diesel engine. The engine specifications are given in Table 1.

The test engine was coupled to a hydraulic dynamometer providing a maximum engine power of 110 KW with a ±0.1 KW of uncertainty to control engine speed and load. The test engine was operated at different torques when different fuels were tested. The load on the dynamometer was measured by using a strain gauge load sensor that was calibrated by using standard weights just before the experiments. An inductive pickup speed sensor was used to measure the speed of the engine, and it was also calibrated by an optical tachometer. An AVL DICOM4000 gas analyzer was used to measure CO, CO2, NOx and HC emissions.

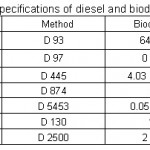

In the experiments, diesel fuel no. 2 and four diesel fuel/biodiesel blends were tested. Waste frying oil methyl ester was blended with diesel fuel in 0%, 20%, 40%, 60% and 80% proportions by volume. The blends were prepared just before the experiments. In the tests, wasted frying oil was supplied from Modares university biodiesel institute. The specifications of the waste frying oil methyl ester are shown in Table 2.

All fuels were tested at 1800 rpm and four engine partial loads (25%, 40%, 65% and 80%). The general testing procedure can be summarized as follows. The engine was run with the diesel fuel. After completion of standard warm-up duration, the engine speed was increased to 3000 rpm. The tests and data collection were performed at four different engine loads. The engine was kept running to flush out the diesel/biodiesel blend from the fuel lines, injection pump and the injectors for a while before shutting down.

Analysis and Results

Experiments were performed at the rated torque speed of 1800 rev/min, and at 25%, 40%, 65% and 80% engine loads.

At each engine load, experiments were carried out for diesel and each blended fuel. In this paper, the effects of engine load and biodiesel on emissions included HC, CO, CO2 and NOx were investigated.

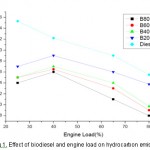

As shown in Fig. 1, for Diesel, the HC emission decreases with increase of engine load, due to the increase in combustion temperature associated with higher engine load. For biodiesel blended fuel, the HC emission is lower than that of diesel and decreases with increase of biodiesel in the fuel. However, for the biodiesel blended fuel, the HC emission, instead of decreasing straightly with engine load, has a peak value at the 40% engine load. The reduced HC emission with biodiesel blended diesel can be accounted for by several reasons as stated in Lapuerta et al. (2008)[8]. However, the lower volatility of biodiesel compared with diesel contributes to the larger difference in HC emission at low engine loads. The maximum concentrations of HC are 35 ppm, 29 ppm, 27 ppm, 26 ppm and 25 ppm, respectively, for diesel, B20, B40, B60, B80, indicating that the maximum HC emission declines with the addition of biodiesel.

The characteristics of CO emission are shown in Fig. 2. For each fuel, there is a decrease of Co emission on increase of the engine load. The peak concentrations at the 25% engine load are 0.04%, 0.037%, 0.036%, 0.035% and 0.035%, respectively, for diesel, B20, B40, B60, B80. The higher combustion temperature at higher engine load contributes to the general decreasing trend. With the addition of biodiesel, CO emission also decreases. It is possible that the oxygen contained in the fuel enhances complete combustion in the cylinder and reduces CO emission.26,27 Fig.3 compares the CO2 emissions of various fuels used in the diesel engine. The CO2 emission increases with increases in load, as expected. The lower percentage of biodiesel blends emits very low amount of CO2 in comparison with diesel. B20 emits very low level of CO2 emissions. Using higher concentration biodiesel blends as the fuel, CO2 emission is found to increase. But, its emission level is lower than that of the diesel mode. B80 emits more amount of CO2, as compared to that of biodiesel blends. More amount of CO2 in exhaust emission is an indication of the complete combustion of fuel. This supports the higher value of exhaust gas temperature.

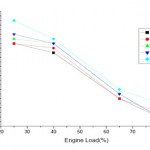

Fig.4 shows the variation of NOx emission with engine load. The NOx concentration increases with increase of engine load for all the fuels. Compared with diesel, NOx emission of the biodiesel blended fuel increases slightly at all tested engine loads and the increase is more obvious at higher engine loads. From diesel to B80, the NOx emission increases. The peak concentrations at the 80% engine load are 670 ppm, 640 ppm, 640 ppm, 620 ppm and 600 ppm respectively, for diesel, B20, B40, B60, B80.

|

Table 1: Specifications of the test engine Click here to View table |

|

Table 2: Specifications of diesel and biodiesel fuels Click here to View table |

|

Figure 1: Effect of biodiesel and engine load on hydrocarbon emission Click here to View figure |

|

Figure 2: Effect of biodiesel and engine load on CO emission Click here to View figure |

|

Figure 3: Effect of biodiesel and engine load on CO2 emission Click here to View figure |

|

Figure 4: Effect of biodiesel and engine load on NOx emission Click here to View table |

Conclusion

Experiments have been conducted on a diesel engine using diesel, diesel-biodiesel blended fuels. Biodiesel used in the present study was manufactured from waste frying oil. Blended fuels containing 20%, 40%, 60% and 80% by volume of biodiesel, were used in the tests. The effect of engine load and fuel mix on emissions was investigated. The use of diesel blended with biodiesel, compared with diesel on the emissions; in general, HC and CO emissions are higher at low engine loads and lower at high engine loads while NOx increase with engine loads. Also the CO2 emission increases with increases in load, as expected. The lower percentage of biodiesel blends emits very low amount of CO2 in comparison with diesel. After the addition of biodiesel in the blended fuel, HC and CO emissions decrease due to improved combustion with oxygen enrichment of the fuel. However, NOx emissions increase due to the higher combustion temperature and the increased oxygen level in the combustible mixtures.

References

- Agarwal AK. (2007), Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines. Prog Energy Combust Sci ;33:233–71. http://dx.doi.org/10.1016/j.pecs.2006.08.003

- Demirbas A. (2005). Biodiesel impacts on compression ignition engine (CIE): Analysis of air pollution issues relating to exhaust emissions. Energy Sources, 27(6):549-558. http://dx.doi.org/10.1080/00908310490449207

- Ribeiro NM, Pinto AC, Quintella CM, Rocha GOD, Teixeira LSG, Guarieiro LLN, et al. (2007), The role of additives for diesel and diesel blended (ethanol or biodiesel) fuels: a review. Energ Fuel ;21:2433–45. http://dx.doi.org/10.1021/ef070060r

- Cvengroš J, Považanec F. (1996), Production and treatment of rapeseed oil methyl esters as alternative fuels for diesel engines. Bioresour Technol ;55:145–52. http://dx.doi.org/10.1016/0960-8524(95)00190-5

- USEPA. (2002), A comprehensive analysis of biodiesel impacts on exhaust emissions; EPA. 420-P-02-001.

- Srivathsan VR, Srinivasan LN, Karuppan M. (2008), An overview of enzymatic production of biodiesel. Bioresour Technol ;99(10):3975–81. http://dx.doi.org/10.1016/j.biortech.2007.04.060

- Kulkarni MG, Dalai AK. (2006), Waste cooking oil—an economical source for biodiesel: a review. Ind Eng Chem Res;45:2901–13. http://dx.doi.org/10.1021/ie0510526

- Lapuerta M, Rodriguez-Fernandez J, Agudelo JR. (2008), Diesel particulate emissions from used cooking oil biodiesel. Bioresour Technol ;99:731–740. http://dx.doi.org/10.1016/j.biortech.2007.01.033

- Cherng-Yuan L, Lin H-A. (2007). Engine performance and emission characteristics of a three-phase emulsion of biodiesel produced by peroxidation. Fuel Processing Technol. 88(1): 35-41. http://dx.doi.org/10.1016/j.fuproc.2006.07.008

- Demirbas A. (2007), Progress and recent trends in biofuels. Prog Energy Combust Sci ;33:1-18. http://dx.doi.org/10.1016/j.pecs.2006.06.001

- Rakopoulos CD, Antonopoulos KA, Rakopoulos DC. (2006). Comparative performance and emissions study of a direct injection diesel engine using blends of diesel fuel with vegetable oils or biodiesels of various origins. Energy Conver. Manage. 47(18-19): 3272-3287. http://dx.doi.org/10.1016/j.enconman.2006.01.006

- Ulusoy Y, Tekin Y, Çetinkaya M, Karaosmano_lu F. (2004). The engine tests of biodiesel from used frying oil. Energy Sources, 26: 27-932. http://dx.doi.org/10.1080/00908310490473219

- Kaplan C, Arslan R, Sürmen A. (2006). Performance Charecteristics of Sunflower Methyl esters as Biodiesel. Energy Sources, 28: 751-755. http://dx.doi.org/10.1080/009083190523415

- Çetinkaya M, Karaosmano_lu F. (2005). A new application area for used cooking oil originated biodiesel: Generators. Energy Fuels, 19(2): 645-652. http://dx.doi.org/10.1021/ef049890k

- Hamasaki K, Kinoshita E, Tajima H, Takasaki K, Morita D. (2001). Combustion characteristics of diesel engines with waste vegetable oil methyl ster. The fifth International Symposium on Diagnostics and Modeling of Combustion in Internal Combustion Engines (COMODIA 2001). Nagoya, Japan.

- Lapuerta M, Armas O, Jose RF. (2008), Effect of biodiesel fuels on diesel engine emissions. Prog Energ Combust ;34:198–223. http://dx.doi.org/10.1016/j.pecs.2007.07.001

- Tat ME. (2003). Investigation of oxides of nitrogen emissions from biodiesel-fueled engines. PhD thesis. Iowa State University.http://www3.me.iastate.edu/biodiesel/Technical Papers/Dissertati on_link.htm.

- Çanakçi M, VanGerpen JH. (2003). Comparison of engine performance and emissions for petroleum diesel fuel, yellow grease biodiesel, and soybean oil biodiesel. Trans. ASAE, 46(4): 937-944.

- Mittelbach M, Tritthart P. (1988). Diesel fuel derived from vegetable oils, III. Emission tests using methyl esters of used frying oil. J American Oil Chemists’ Soc. 65(7): 1185-1187.

- Payri F, Macián V, Arregle J, Tormos B, Martínez JL (2005). Heavy-duty diesel engine performance and emission measurements for biodiesel (from cooking oil) blends used in the ECOBUS project. SAE paper. 2005-01-2205.

- Aakko P, Nylund NO, Westerholm M, Marjamäki M, Moisio M, Hillamo R. (2002). Emissions from heavy-duty engine with and without after treatment using selected biodiesels. FISITA 2002 World Automotive Congress Proceedings; F02E195.

- Dorado M, Ballesteros E., Arnal J, Gomez J, Lopez F. (2003). Exhaust Emissions from a Diesel Engine Fueled with Transesterified Waste Olive Oil. Fuel, 82: 1311-1315. http://dx.doi.org/10.1016/S0016-2361(03)00034-6

- Murillo S, Mı´guez JL, Porteiro J, Granada E, Mora´n JC. (2007). Performance and exhaust emissions in the use of biodiesel in outboard diesel engines. Fuel, 86: 1765-1771. http://dx.doi.org/10.1016/j.fuel.2006.11.031

- Meng X, Chen G, Wang Y. (2008). Biodiesel production from waste cooking oil via alkali catalyst and its engine test. Fuel Processing Technol. 89: 851-857. http://dx.doi.org/10.1016/j.fuproc.2008.02.006

- Lin Y, Wu YG, Chang CT. (2007). Combustion characteristics of waste oil produced biodiesel/diesel fuel blends. Fuel, (86): 1772-1780. http://dx.doi.org/10.1016/j.fuel.2007.01.012

- Ullman, T.L., Spreen, K.B., Mason, R.L. (1994), Effects of cetane number, cetane improver, aromatics and oxygenates on 1994 heavy-duty diesel engine emissions. SAE Tec Pap Ser; No. 941020.

- Ramadhas AS, Muraleedharan C, Jayaraj S. (2005), Performance and emission evaluation of a diesel engine fueled with methyl esters of rubber seed oil. Renew Energy;30:1789–800. http://dx.doi.org/10.1016/j.renene.2005.01.009