An Experimental Study on Effect of Nano-Materials on Mixing And Compaction Temperature of Limestone Nature HMA

Mohammad Reza Rafiee1 and Navid Javid1 *

1

Manager of Production and Technical Services of Isfahan Municipal Construction Organization,

Isfahan,

Iran

2

Head of Soil Mechanics Engineering Laboratory of Isfahan Municipal Construction Organization,

Isfahan,

Iran

DOI: http://dx.doi.org/10.12944/CWE.10.Special-Issue1.58

Nano- technology is a new field of science that deals with materials in Nano scale. One of the problems that solved by Nano-technology is the problem of striping in silica nature asphalts. Some new products include zycosoil, zycosil and zycotherm was produced to improve this problem. These materials make the aggregate surface hydrophobic by penetration in them and react with their silica content. In this study, we tried to investigate the effect of Nano-materials to quality of limestone asphalts. Compaction temperature reduction is a positive specification of these materials on siliceous asphalts that is investigated in this study on Calcareous asphalts. In this study, many experiments have been done on asphalt binder without additive, asphalt binder with additive, Aggregates, conventional asphalts and zycotherm contained asphalts. Therefore, consequently, in respect to experiments we found that reduction in mixing temperature and compaction temperature would be about 5°C. It is also found that this material will increase asphalt resistance by 5 percent.

Copy the following to cite this article:

Rafiee M. R, Javid N. An Experimental Study on Effect of Nano-Materials on Mixing And Compaction Temperature of Limestone Nature HMA. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). DOI:http://dx.doi.org/10.12944/CWE.10.Special-Issue1.58

Copy the following to cite this URL:

Rafiee M. R, Javid N. An Experimental Study on Effect of Nano-Materials on Mixing And Compaction Temperature of Limestone Nature HMA. Special Issue of Curr World Environ 2015;10(Special Issue May 2015). Available from: http://www.cwejournal.org/?p=9452

Download article (pdf) Citation Manager Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2014-11-16 |

|---|---|

| Accepted: | 2014-03-15 |

Introduction

Nano- technology is a branch in applied sciences that cover a wide field of subjects. The main subject of that is investigation of materials and devices that their dimensions are less that 1micrometeror about 1 to 10 nm. Indeed, Nano-technology can be considered as understanding and applying of new properties of materials and devices in such dimensions that lead to create new physical effects that are due to the effect of quantum properties and classic properties. In the 3rd industrial era, Nano-technology is a hung phenomenon that entered in all scientific fields and it is considered as a new technology that is developing with maximum speed. From the first decade of 1980, designing and building new structures were have been witness of new innovations by more applicable building materials from the aspect of resistance, formability, Durability and being more powerful than conventional materials.

Nano- technology is a completely interdisciplinary field of study and is related to majors include material engineering, Medicine, pharmacist, veterinary, biology, applicable physic, semi-conducted tools, super-molecules chemistry and even mechanical engineering, electrical engineering, civil engineering and chemical engineering. Interpreters believe that the three sciences that have formed 3rd industrial era include Nano-technology, Bio-technology and Information technology (Keramat Azar et al., 2014). Nano–technology can be considered as continuance of contemporary science in Nano- dimension or planning of contemporary science. After countries such as China, USA, Germany and France, Iran is located the 7th country which is working on this field (Mohammadi, 2013).

In this study, we investigate the effect of a Nano-material with the trade name of zycotherm. Manufacturer of zycotherm which is produced by Nano-technology claims that it can improve the coating properties of bitumen on silica aggregate and make it better and more integrated compaction and also eliminate stripping and therefore provide asphalt with better durable properties and lifetime. In 2012, Moghadas Nejad and et al measured the effect of a similar material named zycosil on silica and limestone asphalts (Moghadas Nejada et al., 2012). they found that using of zycosil can increase tensile strength coefficient in siliceous asphalts by 14 percent and of the limestone ones by 3 percent. They also found that zycosil can increase strength of siliceous asphalts by 25 percent by considering their conditions and chemical properties of them and of limestone asphalt by 60%. In this study, we have tried to find the effect of this Nano-material on the quality of limestone asphalts.

Materials

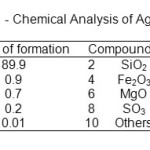

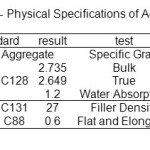

Aggregate: The aggregate that used in this study was angular crushed stone and mined from limestone mountain of Rezvan. This mountain located in the east of Isfahan. More than 90% of used asphalt concrete in the city of Isfahan is produced by these aggregates. Chemical analysis of this material is shown in table 1. Table 2 shows physical properties of this material.

|

Table1: Chemical Analysis of Aggregates Click here to View table |

|

Table2: Physical Specifications of Aggregates Click here to View table |

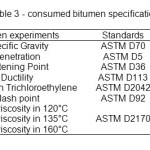

Bitumen: The bitumen which is used in this study is produced by Naft-e-Jey Company and refined in Isfahan refinery plant. The penetration value of this bitumen is 60-70 and table 3 shows its physical properties.

|

Table3: consumed bitumen specifications Click here to View table |

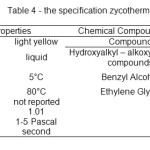

Additive: The additive which is used in this study is Zycotherm that is an improved organosilane compound that is formed from organo groups. Like zycosoil and zycosil, zycothermis introduced by Zydex Company as a water-proof material that forms chemical bond with silica on the surface of aggregate. Table 4 provides specifications and properties of zycotherm. This is a toxic material and cause health risk. In the case of touching with eyes and skin, it should be rinsed for 10 to 15 minutes (Zydex, 2013).

|

Table4: the specification zycotherm Click here to View table |

Experiments

In this study, we compared simple bitumen and bitumen with additive viscosity in different temperatures. Then in respect to appropriate mixing and compaction viscosity, the temperature rate was selected and two kinds of asphalts (The first by simple bitumen and second by bitumen with additives) were produced with three different mixing and compaction temperature with the same mixing designe and three samples from each of them were produced. Then we Measured, calculated and compared different properties of them. The result is given in the next part.

Mixing of Bitumen and Additive: As according to its manufacturer company, the mixing dosage of zycotherm is 0.05 to 0.15 of weight percent of bitumen, we selected the mixing does of 0.1 percent for manufacturing of bitumen with additive. First, we heated 1 kilogram of bitumen in the oven and them according to mixing protocol of zycotherm (Zydex, 2012), 1 gram of that was added to the center of the bitumen. Figure 1 provides the mixing steps of zycotherm.

|

Figure1: Steps of Mixing of Zycotherm Click here to View figure |

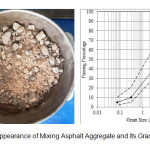

Aggregate Gradation: In respect to the aggregate Gradation in the 4th column of table 1 of INSO-14850 (ISIRI, 2012), the Gradation of compared asphalts was selected according to figure 2. Figure 2 provides also appearance of mixing particles as well as aggregates.

|

Figure2: Appearance of Mixing Asphalt Aggregate and Its Gradation Graph Click here to View figure |

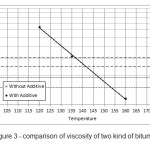

Experiment Design: We first compared and measured viscosity of two samples of bitumen with and without additive in three temperatures of 120, 135 and 160°C. The graphs on figure 3 provide viscosity of these 2 kinds of bitumen. The limits of mixing and compaction are also determined in figure 3.

|

Figure3: comparison of viscosity of two kind of bitumen Click here to View figure |

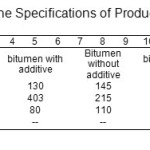

Corresponding 4% air void, the optimum percentage of bitumen is 4.6%. That is according to the experimental mixing design of HMA with and without additive that its results does not bring here. In this study, all the produced asphalt samples have this bitumen percentage. According to this design, 2 series of asphalt samples were mixed and compacted. First one is with bitumen and without additive and second one is with bitumen and additive in different temperatures. Mixing temperature and compaction of samples was selected by considering allowed rates of viscosity and by the aim of increasing of the performance of bitumen. Table 5 provides the specifications of 18 samples.

|

Table5: The Specifications of Produced Materials Click here to View table |

|

Figure4: appearance of produced samples after fraction Click here to View figure |

We measured and calculated specific gravity, air void, Marshall Resistance and Plastic Flow of samples after producing them. Figure 4 shows the samples appearance after their failure. In graphs of figure 5 to 8 we compared asphalts that produced with 2 kinds of bitumen in different temperatures. Figure 5 shows a comparison and change on specific gravity of asphalts. Figure 6 shows the difference of air void of asphalts. While figure 7 also shows the difference of Marshall Resistance and ultimately figure 8 shows Plastic Flow of them.

|

Figure5, 6, 7 & 8: A Comparison between Specific Gravity, Air void, Marshall Resistance and Plastic Flow of Asphalt Produced by Bitumen with and without Additives Click here to View figure |

Result and Discussion

These experiments was done by the aim of investigation of effect of using Nano-material of zycotherm in mix temperature and compaction of asphalts and the main aim was investigation of possibility of reduction in mix temperature and asphalt compaction in the case of using Nano- materials.

As the silanol group of this Nano-material reacts with silicon of the surface of aggregate, not only it makes them hydrophobic, but also reinforces the bond between bitumen and aggregates. And also as the limestone aggregate contains a little siliceous compound (limestone which is used in this study contains 3.7% silica according to table1), so we think these Nano-material has not significant effects on limestone materials. As you can see in figure 6, both kinds of asphalts have reached to 4% air void in temperature about 130°C and temperature difference for the same air void is just about 5°C.

It means that in the case of using this material, we can reduce the temperature of mixing and compaction by 5°C.

Figure 6 shows that although necessary temperature to asphalt compaction does not change Significantly, produced asphalts with bitumen and additive shows better compaction, while compaction changes with temperature in additive contained asphalts is about half of conventional asphalts. In figure 7 it is seen clearly that in the case of using the additive of zycotherm, the asphalt resistance would increase by 5%. In figure 8, there are not clear behaviors in plastic flow of asphalt.

Finally, as the problem of stripping in limestone asphalts is less than siliceous asphalts and by considering slight improvement in specifications of asphalt by using these Nano-materials, and also high cost of them and difficulties in their usage and maintenance of them, producing this kind of asphalt it is not economic.

Acknowledgment

We thank to management of Exir-e-Sharqh Company, the monopole representation of Zydex Industry in Iran, because of their nice cooperation and providing zycotherm sample with scientific and technical documents of Zydex Company.

Reference

- Keramat Azar, Z. Beigi, F and Hajeb,S. Reviews The Status of Self Repair of Smart Materials and Sustainable Architecture. First Iranian National Conference on Architecture, Restoration, Urban Environment and Sustainable. Hamadan (2014).

- Mohammadi, J.Iran and Nono technology. Retrieved 8 Jun 2013 from: http://www.asriran.com /fa/news/278314/. (2013).

- Moghadas Nejada, F.; Azarhooshb, A.R.; Hamedia, GH.H.; Azarhooshc, M.J.; Influence of using nonmaterial to reduce the moisture susceptibility of hot mix asphalt. Construction and Building Materials, 31, 384–388(2012).

- Zydex Industries,. Material Safety Data Sheet of ZycoTherm (Zydex, 2013).

- Zydex Industries,. Laboratory Test Protocol – ZycoTherm – Mixing protocol (Zydex 2012).

- Institute of Standards and Industrial Research of Iran,. Hot Mix Asphalt – Technical Specification. INSO 1485,0 ICS: 93.080. (2012).