Experimental Investigations on Packed Bed Solar Air Heater

M.K. Lalji1 * , R.M. Sarviya2 and J.L. Bhagoria2

DOI: http://dx.doi.org/10.12944/CWE.6.1.22

Solar collector is important component of active solar heating systems. It has been observed that the performance of flat plate collector improves appreciably by packing its duct with blackened wire screen matrices and this improvement is a strong function of bed and operating parameters. In this paper an experimental test setup is designed and fabricated. Performance evaluation of packed bed Solar air heater using wire mesh screen matrices and its comparison with conventional design has been done. Data collection at different mass flow rates for a number of configurations has been done. Further suitable recommendations have been made accordingly.

Copy the following to cite this article:

Lalji M.K, Sarviya R.M, Bhagoria J.L. Experimental Investigations on Packed Bed Solar Air Heater. Curr World Environ 2011:6(1);151-157 DOI:http://dx.doi.org/10.12944/CWE.6.1.22

Copy the following to cite this URL:

Lalji M.K, Sarviya R.M, Bhagoria J.L. Experimental Investigations on Packed Bed Solar Air Heater. Curr World Environ 2011:6(1);151-157. Available from: http://www.cwejournal.org/?p=1307

Download article (pdf)

Citation Manager

Publish History

Select type of program for download

| Endnote EndNote format (Mac & Win) | |

| Reference Manager Ris format (Win only) | |

| Procite Ris format (Win only) | |

| Medlars Format | |

| RefWorks Format RefWorks format (Mac & Win) | |

| BibTex Format BibTex format (Mac & Win) |

Article Publishing History

| Received: | 2011-04-25 |

|---|---|

| Accepted: | 2011-05-29 |

Introduction

Solar air heaters have been observed to have generally poor convective heat transfer coefficient from absorber plate to the air. This low heat transfer coefficient results in relatively higher absorber plate temperature leading to higher thermal losses to the environment and hence lower thermal efficiency. It is therefore, necessary to improve convective heat transfer coefficient to increase the thermal efficiency of flat plate solar air heaters. To enhance the thermal efficiency research attempts have been made by modifying the conventional design of solar air heater. Applications of flat plate solar air heater in heating building drying agriculture products and heating green houses etc

Packed Bed Solar Air Heater

The performance of plate collector improves appreciably by packing its duct with blackened wire screen matrices and this improvement is a strong function of bed and operating parameters. Packed bed can be successfully used for the enhancement of heat transfer coefficient in solar air heaters. The air flows through the porous medium on which the solar radiation is directly incident. The radiation penetrates absorbing medium in depth and in turn gets absorbed. The high heat transfer area to volume ratio promotes heat transfer capability and the turbulence producing air flow path through the bed provide for a rapid increase of heat exchange. Use of packed bed for the improvement of performance of solar air heater has been proposed by several investigators. The materials used for packed bed includes wire mesh screen, matrices, pebble bed, chips of different materials etc.

Literature Review and Objective

Thermo hydraulic investigations on a packed bed solar air heater having its duct packed with blackened wire screen matrices of different geometrical parameters (wire diameter and pitch) has been done by Mittal M.K. et al.,14. Based on energy transfer mechanism in the bed, a mathematical model is developed to compute effective efficiency. A design criterion is also suggested to select a matrix for packing the air flow duct of a solar air heater which results in the best thermal efficiency with minimum pumping power penalty. Resulting values of effective efficiency clearly indicate that the packed bed solar air heater investigated is thermo hydraulically efficient as compared to flat plate collectors.

|

Figure 1: Solar air heater principle Click here to View figure |

An experimental investigation carried out by Varshney L. et al.,20 on heat transfer and fluid flow characteristics of a solar air heater having its duct packed with wire mesh screen matrices. The investigations covered a wide range of geometrical parameters of wire mesh screen matrix (wire diameter, pitch and number of layers). Correlations developed for Colburn j-factor and friction factor indicate that heat transfer coefficient and friction factor are strong functions of geometrical parameters of matrices.

In another experimental investigation carried out by Thakur N.S. et al.,19 on a low porosity packed bed solar air heater covering a wide range of geometrical parameters of wire screen matrix, i.e. wire diameter 0.795 to 1.40 mm, pitch 2.50 to 3.19 mm and number of layers from 5 to 12. The correlations have been developed for the Colburn j factor and friction factor for a low range of porosities from 0.667 to 0.880 and packing Reynolds number range from 182 to 1168. It is observed that both the heat transfer coefficient and the friction factor are strong functions of geometrical parameters of the porous packed bed. A decrease in porosity increases the volumetric heat transfer coefficient.

Further experimental study conducted by Nasri Rabadi et al.,15 on enhancing solar energy collection by using curved flow technology coupled with flow in porous media. Porous media (with 0.1453 porosity) composed of coarse aluminum chips fill the flow channels to provide for further increase in heat transfer performance and for extra energy storage capability. Al housing porous medium will decrease the temperature rise across the collector during sunlight. The maximal outlet temperature reached was 73°C for the collector without porous media at 70 l/h flow rate and 60 °C for the collector backed with porous medium at 50 l/h flow rate.

Study on thermal performance conducted by Paswan M.K. et al.,16 on Wire-Mesh Roughened Solar Air Heaters providing wire-screen mesh (metal) as artificial roughened on the underside of its absorber plate. Instead of comparing the efficiency of the same rate of discharge, the same amount of pumping power was employed so that the unequal frictional losses were also taken into account in the comparison of overall heater efficiency. The rating parameters such as plate efficiency factor, heat-removal efficiency factor, over heat loss coefficient, and the effective absorption coefficient are reported for these heaters.

Based on literature review packed bed solar air heating systems with wire screen mesh is used in the present investigation. In this methodology, the desired numbers of layers of wire mesh screen are stacked on top of each other, parallel to back plate of the collector, at equal distances along the depth to form a matrix., it is desirable that the flow at the heat-transferring surface is made turbulent. This can be done by placing a material in the path of air flow.

It may be recalled that the parameters that strongly influence the heat transfer coefficient and friction factor include porosity, P which is determined by the geometry i.e. diameter and pitch of individual wires in the mesh and number of layers that have been filled into a given space; and the flow rate of air through the bed. Earlier studies have shown that the systems and flow parameters that are considered important to influence the heat transfer and friction characteristics are given below:

- Packed bed Reynolds number, Rep

- Porosity

Material and Methods

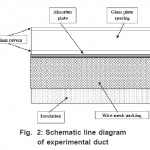

The schematic diagram of experimental set-up used in the present investigation, is shown in Fig. 2 has been designed, fabricated,and used for data collection on heat transfer and fluid flow characteristics of solar air heaters with packed bed and without packed bed. It consisted of a test section having two identical ducts, one smooth duct (like that in a solar air heater in common use) and the other one identical in size but provided with a packed bed using wire screen matrices. Both the ducts had an identical length of 1.60 m, width of 0.62 m, and depth of 0.025 m and were made of softwood, both inclined at an angle of 25° to the horizontal. The smooth (or conventional) duct had an absorber plate of 2 mm GI sheet. It was blackened with black board paint on the side facing solar radiation. It had a 3 mm thick glass sheet cover fixed 20 mm above the absorber plate. The sides and bottom of the duct were insulated with thermocol sheet. (Thermocol is a commercial insulation of foamed polystyrene having a thermal conductivity 0.037 W/m/K). The reason for using two ducts in the present set-up was to compare the performance at the same operating conditions such as mass flow rate, insolation and inlet fluid temperature. The packed bed duct had a 2 mm GI sheet having several layers of wire mesh screens arranged one above the other on the upper side of the GI sheet while below it there was 50 mm of thermocol and 12 mm plywood. The sides were made of softwood, 25 mm thick. A glass cover was provided on the upper side which rested on batons fixed adjacent to the sidewall at a height of 25 mm. Another glass cover was fixed at a height of 20 mm above the first one and supported on the frame, leaving a stagnant air gap of 20 mm between the two glass covers. A wooden exit section was provided at the outlet of the test duct, which was followed by a mixing device, namely baffles for mixing the air. The exit section reduced the effect of sudden change on the test section. The mixing device enabled measurement of the bulk mean temperature at the outlet of the test section. The length of the exit section was 0.5 m and the cross section area matched with that of the test duct. Three equally spaced baffle plates which spread over 100 mm length beyond the exit section were provided for the purpose of mixing the hot air coming out of the solar collectors to obtain a uniform temperature of the air at the outlet. The mixing section was connected to the Mild Steel pipefitting through a transition piece and flexible pipes. A 2.2 kW (3.0 h.p.) centrifugal blower was used for drawing air through the duct. A standard set of inlet and outlet pressure taps were provided at a distance of 25.4 mm on each side of the orifice plate. The temperature distribution in the bed and temperature of the air at the inlet and outlet of the test section were measured by means of pre-calibrated copper constantan thermocouples.

A digital micro-voltmeter was used to indicate the output of the thermocouples in mili-volts. The temperature measurement system was calibrated to yield the correct temperature values. The pressure drop across the test section was measured by using a calibrated micro-manometer.

Following are the main components of experimental set-up

|

Figure 2: Schematic Line Diagram of Experimental Duct Click here to View figure |

Test Duct

The duct consists of 1.6 m length, 0.62m width and 0.025 m depth made up of galvanized iron sheet and kept inclined at angle of 25° to the horizontal. The bottom surface of the duct is covered with 2mm aluminum sheet below which 3 mm plywood, below which 50 mm thermocol insulation, supported on another plywood of 3 mm. The sun facing side of aluminium sheet is painted black by the black board paint. A 3 mm thick glass cover is fixed above the absorber plate, which rests on frame having a height of 25 mm. Another glass cover is fixed at a height of 20 mm above the first one support on a frame leaving a stagnant air gap of 20 mm between the two glass covers. The solar air heater has a dimension of 1.6 m x 0.62 m x 0.025 m.

Blower Unit

A centrifugal air blower with 3-phases 3 HP motor is provided with one end connected to the mild steel pipe to suck the air through the test duct.

Orifice Meter

For the measurement of rate of air flow through the test ducts orifice plates have been orifice plate is fixed between two flanges fixed with straights M.S. pipe e.g. 80 mm inner diameter. The length of the M.S.pipe upstream of the orifice meter was 800mm and towards the downstream of orifice plate was 400mm.

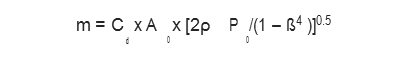

Manometer

A manometer is connected to the pressure taps for the measurement of pressure drop, (ÄP0 ) across each orifice plate. Mass flow rate can be calculated using the following expression:

where,

Cd is the coefficient of discharge

β is the ratio of orifice diameter to pipe diameter

A0 is the orifice area

ρ is the density of air

Both the orifice plates were calibrated using a standard pitot tube.The pitot tube measured the local velocity across the diameter of the pipe having orifice plates.The experimental values of local velocities were used to calculate the average velocity of the air in the pipe. With the knowledge of this average velocity, density of air and cross sectional area of the pipe, mass flow rate of the air were obtained. These values of mass flowrate and reading of manometer yielded the value of the coefficient of discharge.

Pyranometer

A Pyranometer, model No 0052 supplied by M/s National Instruments Ltd Calcutta,India was used to measure the intensity of solar radiation.The Pyranometer was kept at an inclination of 25° with the horizontal, which is also the slope of solar collectors. This way the solar insolation falling on the inclined collector was measured directly from the pyranometer.

Thermometer

Digital thermometer of range 0° to 100°C was used to measure temperatures at the inlet and outlet of air.

Experimental

The experimental data has been collected by following the procedure described in ASHRAE Standard Handbook (1977) for testing the solar air collector operating in open loop mode. Data pertaining to a given mass flow rate was collected between 11 a.m. and 2 p.m. at an interval of 1 hr were taken on a clear sky day. Before starting the experiment, all the joints of duct, inlet section, mixing device and pipe fittings were examined for leakage and leakage was sealed by using glass putty. While recording the temperature, the ice-bath and lead wire for micro-voltmeter were protected from direct solar radiation. The blower was run for an hour and thereafter, the thermocouple readings for wire mesh temperatures at various locations and inlet and outlet air temperatures, pyranometer readings for intensity of solar radiation and manometer readings for pressure drop across the duct were recorded for a particular day. Experimental data were collected for flow rates ranging from 0.0261 to 0.031 kg/s for four set of matrices. First of all a low porosity wire mesh of square shape with 6-layers is used. Afterwards same wire mesh with 5 –layers, 4 & 3 is used and again the above mentioned data was collected.

Results and Discussion

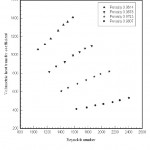

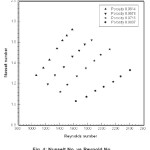

The results have been shown graphically as follows, the data is presented in the form of Nusselt number plot to bring out clearly the effect of parameters and enhancement in heat transfer.

|

Figure 3: Volumetric heat transfer co-efficient vs Reynold No Click here to View figure |

|

Figure 4: Nusselt No. vs Reynold No. Click here to View figure |

From fig 3 & 4 it is seen that heat transfer increases as Renolds no. increase, also from the figure it is clear that as porosities reduces in the duct, heat transfer increase as decrease in porosity increases turbulence and there by increase volumetric heat transfer coefficient and nusselt no.

Conclusion

The packed bed type solar air heater can be successfully used to enhance the heat transfer rate. The heat transfer enhancement is a function of Porosity and operating parameters. The Reynolds number has been found to be a strong parameters affecting heat transfer and friction factor for packed bed solar heater. Heat transfer is high for six layer matrix having porosity (P=0.961) and maximum area to volume ratio (av=335m2) within the range of present investigation. Porosity also strongly influences the heat transfer coefficient and hence thermal performance of packed bed solar air heater. It can also be concluded that a considerable enhancement of heat transfer can be obtained from the packed bed solar air heater by lowering the porosity of the bed. The porosity of the bed governs the performance of packed bed solar air heater at a given Reynolds number, the porosity and area to volume ratio are the key parameters for heat transfer. The Reynolds number also has been found to be a strong parameters affecting heat transfer and friction factor for packed bed solar heater. A solar heater with square void matrix having 6 layer of matrix, is found to yield the best performance in almost the entire range of mass flow rate investigated.(mass flow rate=0.0261-0.033kg/s).

Thus the heat transfer enhancement is a function of Porosity as an operating parameters. Also the Reynolds number has been found to be a strong parameters affecting heat transfer and friction factor for packed bed solar heater.

References

- Ahmad A., Saini J. S. and Varma H. K., Thermohydraulic performance of packed bed solar air heaters. Energy Conv. Manag 37: 205-214 (1996).

- ASHRAE Standard 93-77, Method of testing to determine the thermal performance of solar air heater, New York, 1-34 (1977).

- Bhagoria J.L., Saini J.S., Solanki S.C., Heat transfer coef.cient and friction factor correlations for rectangular solar air heater duct having transverse wedge shaped rib roughness on the absorber plate. Renewable Energy, 25: 341–69 (2002).

- Chiou J. P. and El-Wakil M. M., Heat transfer and flow characteristics of porous matrices with radiation as heat source. J. Heat Transfer 88: 69-76 (1966)..

- Chiou J. P., El-Wakil M. M. and Duffie J. A., A slit and expanded aluminium-foil matrix solar collector. Solar Energy 9: 73-80 (1965).

- Collier R. K., The characterization of crushed glass as a transpired air heating solar collector material. In Proceedings of ISES Silver-Jubilee Congress, Boer K. W. and Glenn B. H. (Eds), Atlanta, GA, pp. 264-268 (1979).

- Coppage J. E. and London A. L. Heat transfer and flow friction characteristics of porous media. Chem. Eng. Progr 52: 57F - 63F (1956).

- Choudhury C, Garg HP and Prakash J, Design studies of packed-bed solar air heaters, Energy Conversion Management. 34(2): 125–138 (1993).

- Dhiman P., Thakur N.S., Kumar A. and Singh S., An analytical model to predict the thermal performance of a novel parallel flow packed bed solar air heater, Applied Energy., 88: 2157–2167 (2011)

- El-Sebaii A.A, Aboul-Enein S, Ramadan MRI, Shalaby SM and Moharram BM, Thermal performance investigation of double pass-finned plate solar air heater. Applied Energy. 88: 1727–1739 (2011).

- Gupta M.K. and Kaushik S.C., Performance evaluation of solar air heater having expanded metal mesh as artificial roughness on absorber plate, Thermal Sciences. 48: 1007-1016 (2009)

- Jain A., Bhagoria J.L., Sharma M.C., Thermal Performance of Solar Air Heater by using Shot Peened absorber plate. Proceedings of 9th International Conference on Shot Peening, Paris., 67-74 (2005).

- Jaurker A.R, Saini J.S.,Gandhi B.K., Heat transfer and friction factor characteristics of rectangular solar air heater duct using rib-grooved artificial roughness. Solar Energy, 80: 895-907 (2006).

- Mittal MK and Varshney L, Optimal thermo-hydraulic performance of a wire mesh packed solar air heater. Solar Energy. 80: 1112–1120 (2006).

- Nasri R., On the performance and entropy generation of the double-pass solar air heater with longitudinal fins, Renewable Energy., 30 (2006).

- Paswan MK and Sharma SP, Thermal performance of wire-mesh roughened solar air heaters. ARISER. 5(1): 31-40 (2009).

- Paul B and Saini JS, Optimization of bed parameters for packed bed solar energy collection system. Renewable Energy. 29: 1863-1876 (2004).

- Singh R, Saini RP and Saini JS, Nusselt number and friction factor correlations for packed bed solar energy storage system having large sized elements of different shapes. Solar Energy. 80: 760-771 (2006).

- Thakur NS, Saini JS and Solanki SC, Heat transfer and friction factor correlations for packed bed solar air heater for a low porosity system. Solar Energy. 74: 319-329 (2003).

- Varshney L and Saini JS, Heat transfer and friction factor correlations for rectangular solar air heater duct packed with wire screen matrices. Solar Energy. 62(4): 255-262 (1998).

- Velmurugan P. and Ramesh P., Evaluation of thermal performance of wire mesh solar air heater, Indian Institute of Science & Technology., 4(1), 12-14, (2011).